Pipeline connection structure and application thereof

A technology of pipes and pipe sleeves, which is applied in the field of connection structure of pipes, which can solve the problems of user influence, difficulty in installation, and separation of pipes from each other, and achieve the effects of convenient assembly, good limit function, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

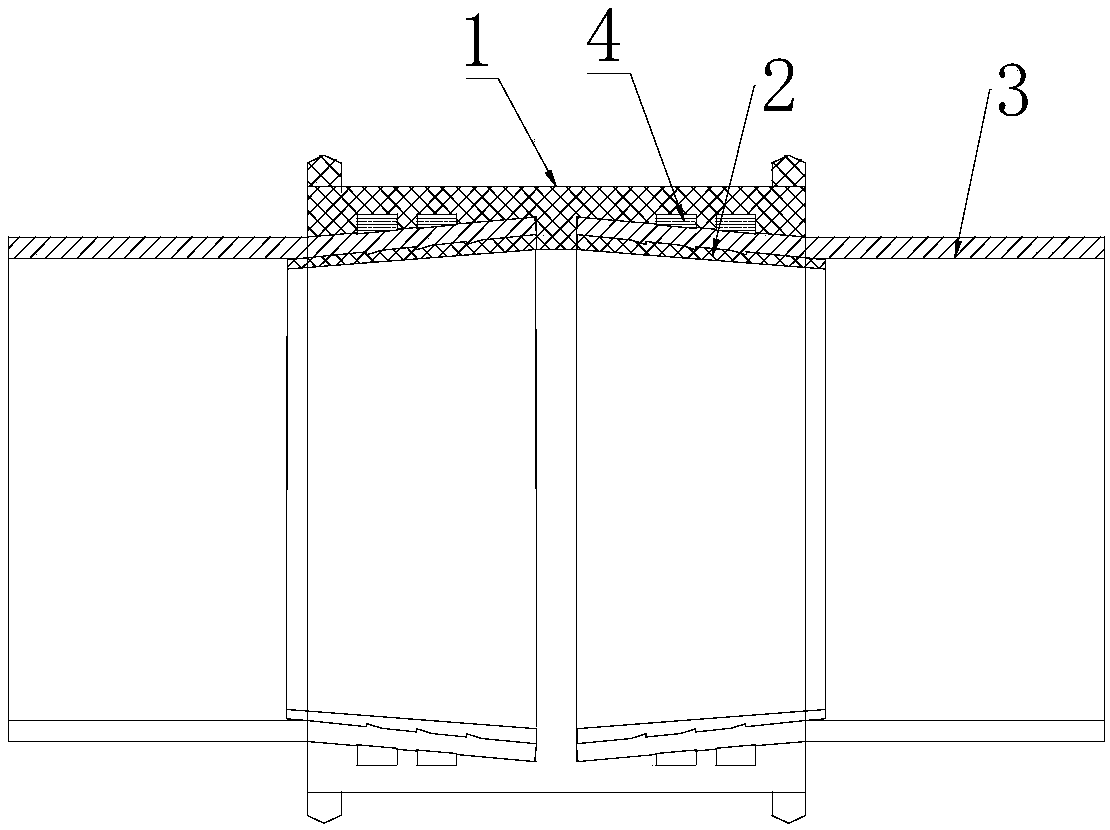

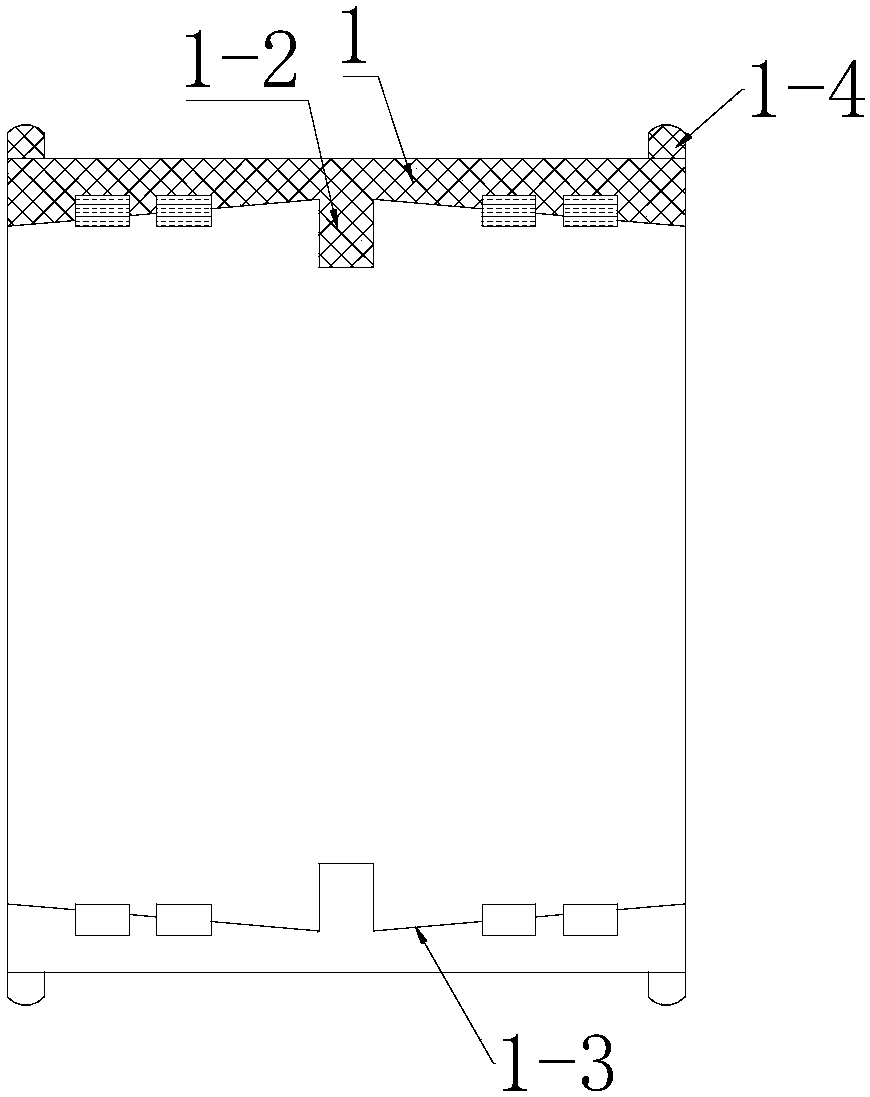

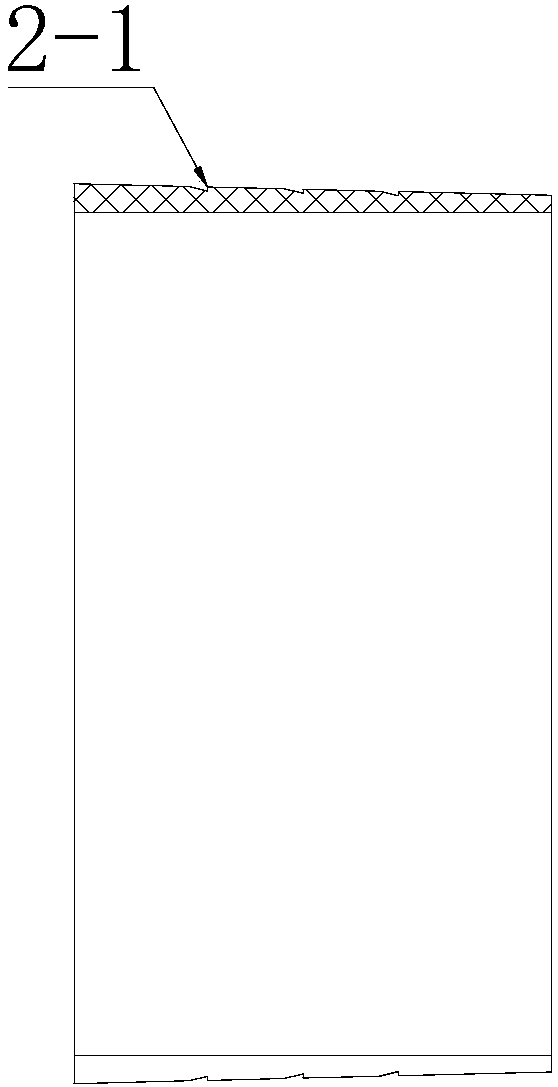

[0034] like Figure 1-Figure 3 As shown, the present invention is a pipeline connection structure, comprising a pipe sleeve 1, a flaring member 2 and two pipes 3 to be connected, the outer diameters of the two pipes are consistent, and the connection of the two pipes is at on the same line. The sleeve 1 is provided with a connection hole 1-1 corresponding to the pipe material 3 and a stop edge 1-2 that is press-fitted with the end of the pipe material. An inclined surface 1-3 is provided inside the connection hole to form a narrow entrance and a wide rear part. The trumpet-shaped structure, the inclined surface is provided with a seal 4, the flared piece is pressed tightly into the connection end of the pipe, and the pipe with the built-in flared piece is inserted into the connection hole. The flaring piece is an annular trumpet-shaped flaring structure, and the side of the flaring piece is provided with a tooth-2-1. It should be noted that the flaring member can also be con...

Embodiment 2

[0039] like Figure 4 As shown, in this embodiment, the pipe sleeve 1 is arranged in the form of an elbow, and the two pipes are correspondingly connected with each other, and the two pipes are connected through the cooperation of the pipe sleeve 1 to form a joint structure perpendicular to each other.

Embodiment 3

[0041] like Figure 5 As shown, in this embodiment, the pipe sleeve 1 is set in the form of a three-way pipe, correspondingly connected to three pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com