Handheld electric pencil sharpener

A pencil sharpener and hand-held technology, which is applied in the field of stationery, can solve the problems that it is difficult to put into the pencil case storage box, the electric pencil sharpener is bulky, and takes up a large volume, and achieves convenient use, simple structure, and reduced processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1, see Figure 1-Figure 12 .

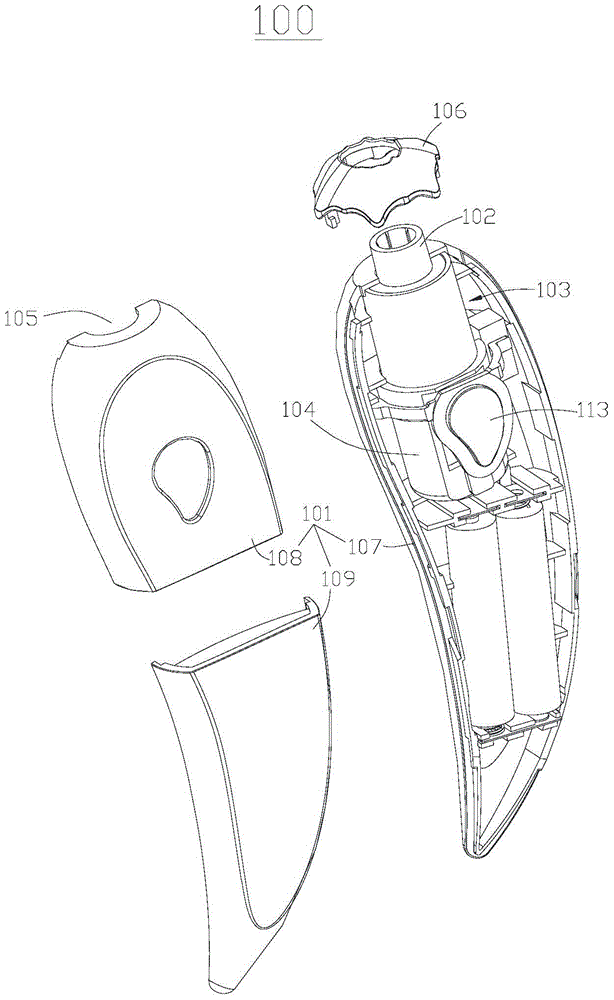

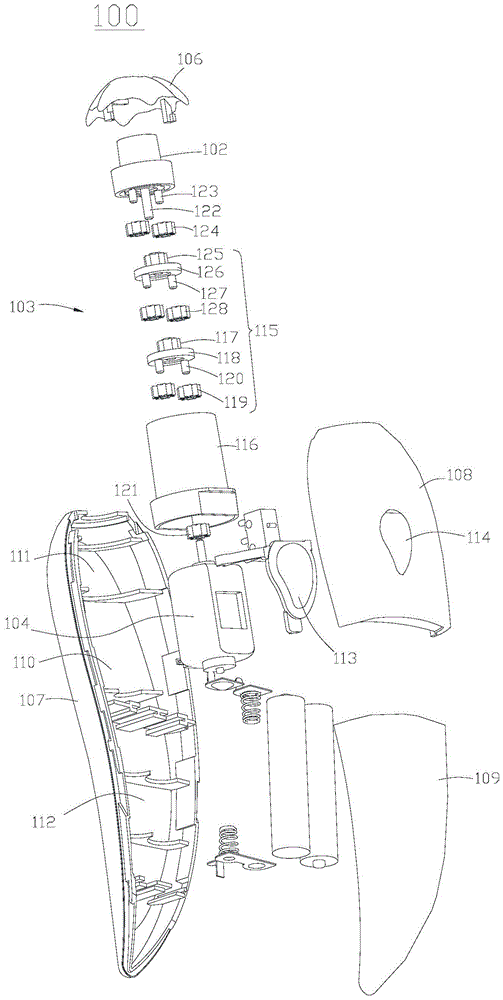

[0041] This embodiment provides a hand-held electric pencil sharpener, such as figure 1 As shown, this handheld electric pencil sharpener includes a housing 101 , a pencil holder 102 , a transmission mechanism 103 and a motor 104 . The casing 101 is in the shape of a strip, and the pencil holder 102 is arranged at the end of the casing 101 , and the pencil holder 102 can rotate relative to the casing 101 .

[0042] Such as figure 1 with figure 2 As shown, the housing 101 is in the shape of a strip, one end of the housing 101 is provided with an opening 105, the pencil chuck 102 is arranged at the opening 105, and the opening 105 is provided with a chuck cover 106, and the chuck cover 106 and the housing 101 are detachable connect. The casing 101 includes a bottom cover 107 , an upper cover 108 and a battery cover 109 . A motor compartment 110 and a transmission compartment 111 are formed between the bottom cover 107 and the ...

Embodiment 2

[0060] Example 2, see Figure 13 .

[0061] This embodiment provides a hand-held electric pencil sharpener. The only difference between this embodiment and Embodiment 1 is the transmission mechanism 103 . Please refer to the description of Embodiment 1 for structures not mentioned in this embodiment.

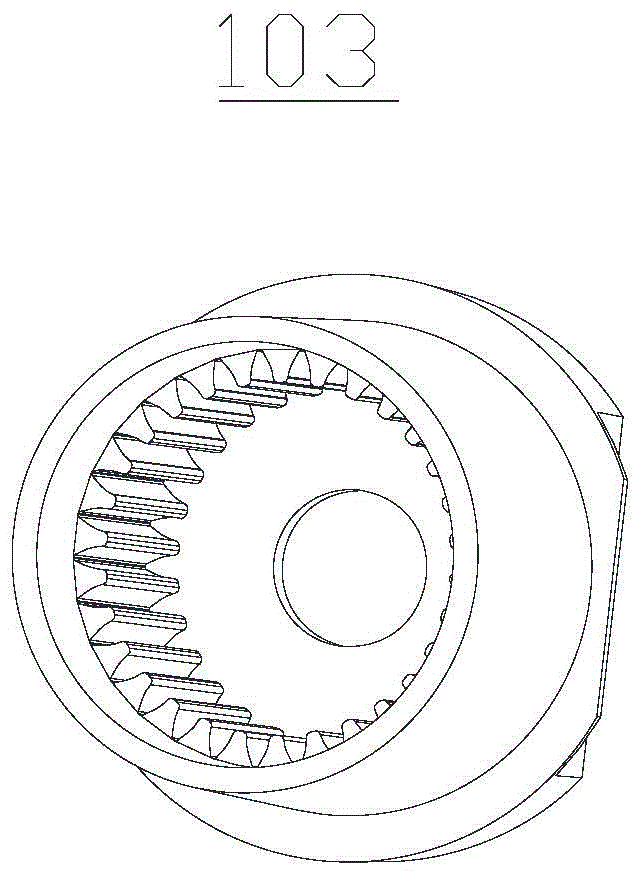

[0062] like Figure 13 As shown, the transmission mechanism 103 includes a planetary gear set 115 and an inner ring gear 116 , and the use of the planetary gear and the inner ring gear 116 as the transmission mechanism 103 can effectively reduce noise. The inner ring gear 116 is fixedly connected with the housing 101 , and the inner wall of the inner ring gear 116 has a plurality of inner teeth distributed along its circumference. The planetary gear set 115 includes a first sun gear 117 , a first planet carrier 118 and two first planet gears 119 .

[0063]The first sun gear 117 is fixedly connected to the first planet carrier 118, the first planet carrier 118 has two first pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap