Electromagnetic energy harvesting system based on passive suspension

A passive suspension and energy harvesting technology, applied in the direction of suspension, elastic suspension, electromechanical devices, etc., can solve the problems of increased distance between the car chassis and the road, complex structure, poor reliability, etc., and achieve good vibration reduction effect , good application prospects, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

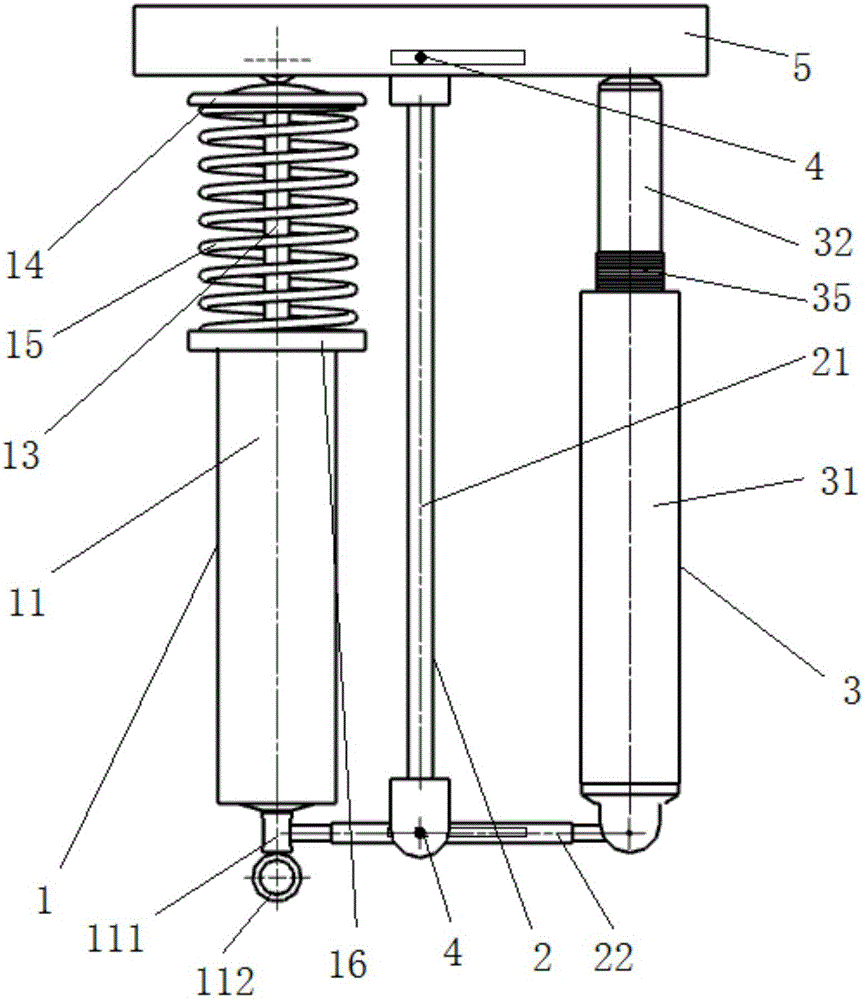

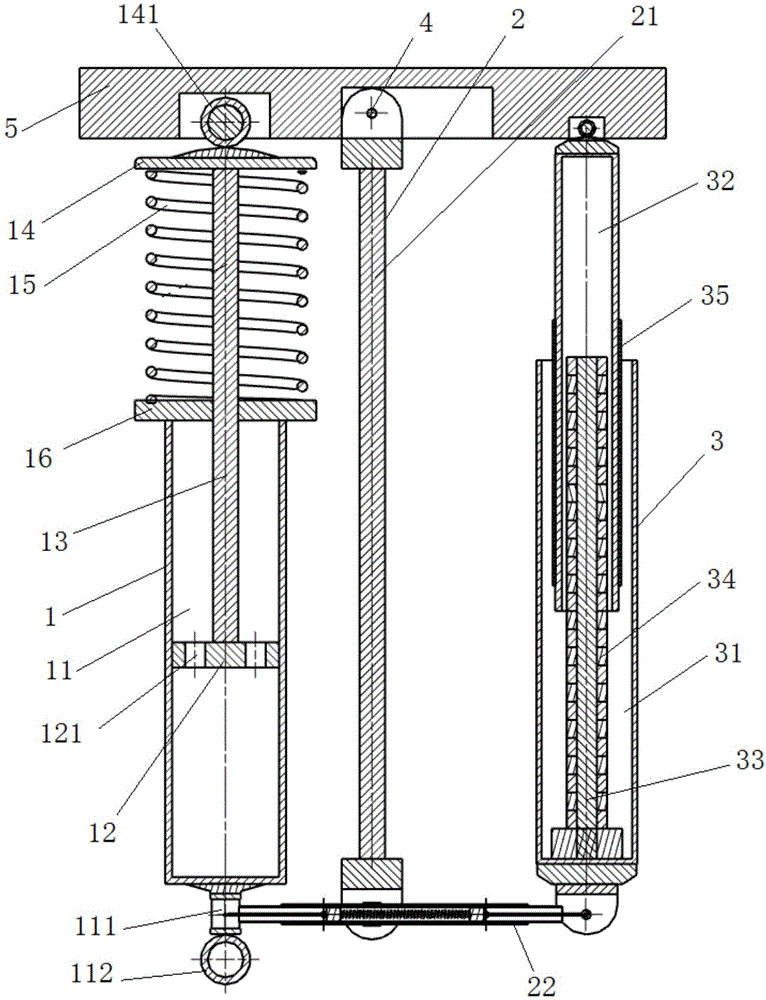

[0028] Such as Figure 1-Figure 8 As shown, an electromagnetic energy harvesting system based on passive suspension includes a hydraulic shock absorber 1 arranged in parallel, a speed amplification mechanism 2 and an electromagnetic energy harvesting mechanism 3, and the speed amplification mechanism 2 is located in the hydraulic shock absorber 1 and between the electromagnetic energy harvesting mechanism 3,

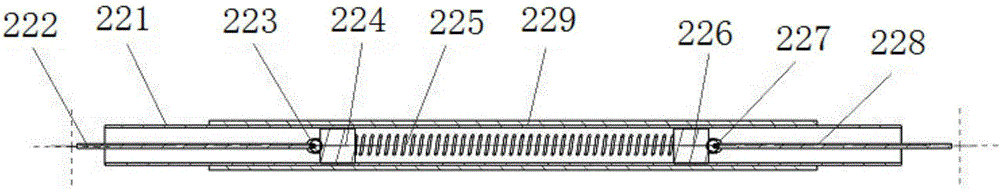

[0029] The speed amplifying mechanism 2 includes support rods 21 parallel to the hydraulic shock absorber 1 and the electromagnetic energy harvesting mechanism 3 respectively, the lower end of the support rods 21 is provided with a speed transmission mechanism 22, and the speed transmission mechanism 22 It includes a guide sleeve 221 and a connecting rod I222, a ball link I223, a slider I224, a spring I225, a slider II226, a ball link II227, and a connecting rod II228 connected sequentially within the guide sleeve 221. The connecting rod I222 The other end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com