Step-type hydraulic bolt lifting mechanism

A lifting mechanism and step-by-step technology, applied in the field of self-elevating offshore platform lifting mechanisms, can solve problems such as plastic deformation of bolts, and achieve the effect of small shape and volume restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

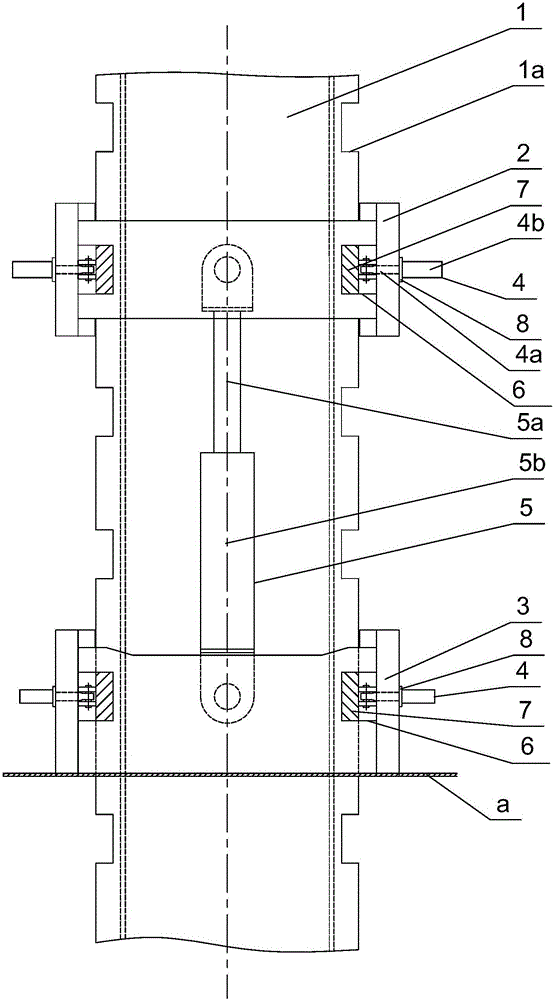

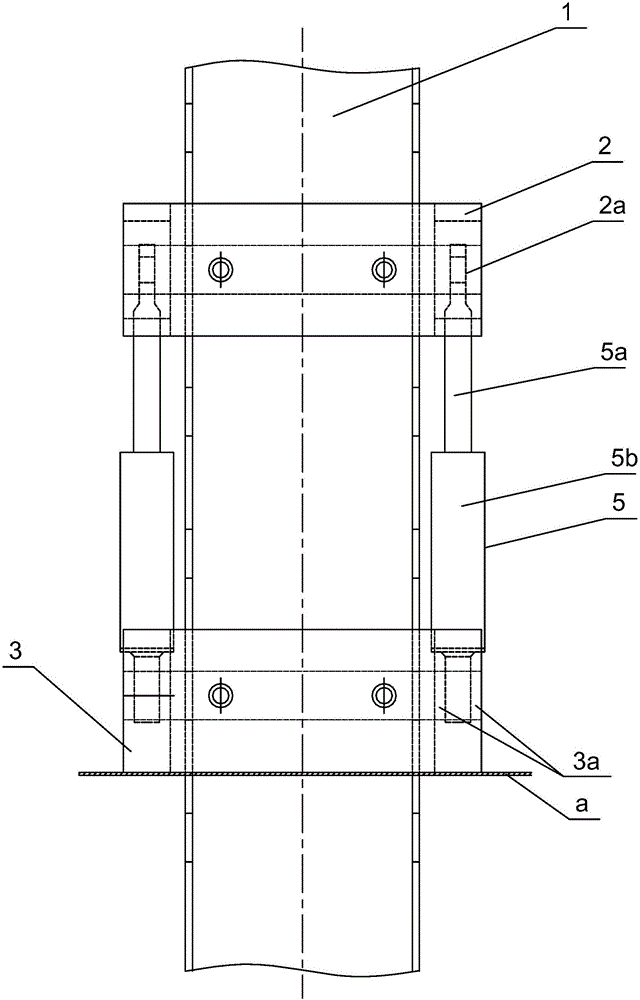

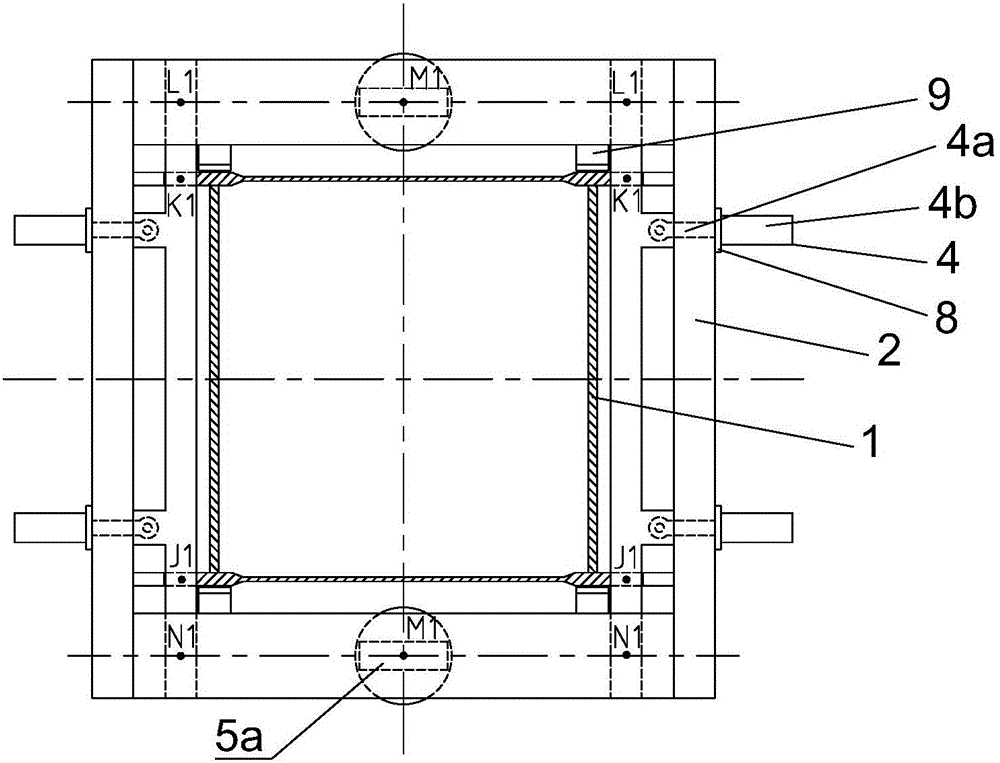

[0022] The embodiment of the present invention provides a step-by-step hydraulic bolt lifting mechanism, such as figure 1 and figure 2 As shown, the step-by-step hydraulic bolt lifting mechanism includes a leg 1, a moving ring beam 2 set on the leg 1, and a fixed ring beam 3 set on the leg 1. The cross section of the leg 1 is rectangular, and the dynamic Both the ring beam 2 and the fixed ring beam 3 are rectangular ring beams matching the pile leg 1; on the two opposite side walls of the pile leg 1, a plurality of horizontally arranged grooves are respectively opened along the length direction of the pile leg 1 1a, the position corresponding to the groove 1a on the moving ring beam 2 and the fixed ring beam 3 is respectively provided with a horizontal chute 6 that can communicate with the groove 1a, and the horizontal chute 6 is horizontally slid and provided with a slot that can be inserted into the groove 1a. The sliding block 7, the sliding block 7 is matched with the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com