Quick detection method for compaction degree of thick-layer aeolian sand roadbed

A detection method, aeolian sand technology, applied in the field of foundation soil survey, infrastructure engineering, construction, etc., can solve the problems of multiple processes, large deviation of moisture content data, and use, etc., to achieve simple operation method and large detection depth , High detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

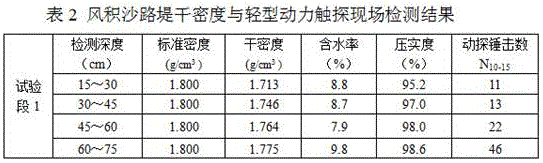

[0034] See Table 1 and Table 2 for the analysis results of aeolian sand particles and the results of dynamic penetrating sounding tests.

[0035]

[0036] For the aeolian sand sample, the content of particles larger than 0.25mm is 40.6%, and the content of particles larger than 0.075mm is 99.6%. The aeolian sand is fine sand.

[0037]

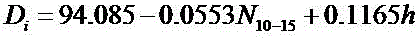

[0038] Compaction D i Number of impacts with dynamic penetration testing N 10-15 The correlation between and detection depth h:

[0039]

[0040]

[0041] R-fit relational correlation coefficient.

[0042] h-detection depth (cm). When the detection depth is 15-30cm, take 15; when the detection depth is 30-45cm, take 30; when the detection depth is 45-60cm, take 45; when the detection depth is 60-75cm, take 60.

Embodiment 2

[0044] See Table 3 and Table 4 for the analysis results of aeolian sand particles and the results of the dynamic penetrating sounding test.

[0045]

[0046] As a result of the analysis of aeolian sand particles, the content of particles larger than 0.25mm is 12.6%, and the content of particles larger than 0.075mm is 98.6%. The aeolian sand is fine sand.

[0047]

[0048]

[0049]

[0050] R-fit relational correlation coefficient.

[0051] h-detection depth (cm). When the detection depth is 15-30cm, take 15; when the detection depth is 30-45cm, take 30; when the detection depth is 45-60cm, take 45; when the detection depth is 60-75cm, take 60.

Embodiment 3

[0053] See Table 5 and Table 6 for the analysis results of aeolian sand particles and the results of dynamic penetrating sounding tests.

[0054]

[0055] As a result of the analysis of aeolian sand particles, the content of particles larger than 0.25mm is 2.8%, and the content of particles larger than 0.075mm is 96.5%. The aeolian sand is fine sand.

[0056]

[0057]

[0058]

[0059] R-fit relational correlation coefficient.

[0060] h-detection depth (cm). When the detection depth is 15-30cm, take 15; when the detection depth is 30-45cm, take 30; when the detection depth is 45-60cm, take 45; when the detection depth is 60-75cm, take 60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com