Fireproof I-shaped high-strength bamboo laminated wood beam and preparation method thereof

A glulam, I-shaped technology, applied in joists, girders, trusses, etc., can solve the problems of imperfect bamboo and wood structure design theory, unfavorable standardized production, fire code restrictions, etc., to break the fire code restrictions, improve The bearing efficiency of beams and the effect of anti-seismic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a fireproof I-shaped high-strength bamboo laminated beam, comprising the following steps:

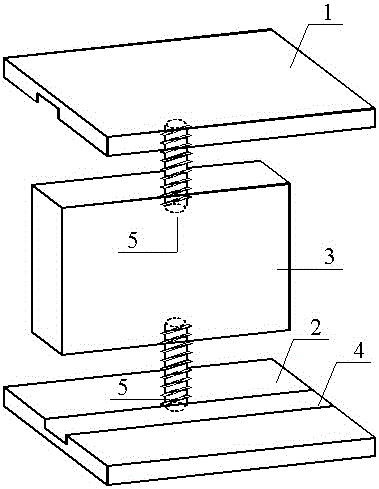

[0027] (1) All components of the fireproof I-shaped high-strength bamboo glulam beam are the upper flange 1 of high-strength bamboo glulam, the lower flange 2 of high-strength bamboo glulam and the web 3 of high-strength bamboo glulam through B low-density glulam for shear resistance Bamboo screws and bamboo pins 5 are assembled together, and at the same time, they are coated with a fireproof, solvent-free and environmentally friendly coating to improve the fire resistance of structural members. The length and width of the I-shaped high-strength bamboo glulam beams are determined by design requirements. The height is adjusted through the height of the web according to the stress;

[0028] (2) High-strength bamboo glulam flange, its manufacturing steps include

[0029] 1) High-strength bamboo glulam is used, and the original bamboo with a bamboo age of 4 ye...

Embodiment

[0048] Fireproof I-shaped high-strength bamboo glulam beam, its structure includes high-strength bamboo glulam upper flange 1 (with slot 4 in the middle), high-strength bamboo glulam lower flange 2 (with slot 4 in the middle), high-strength bamboo glulam Plate 3, low-density bamboo laminated wood shear-resistant bamboo screws and bamboo pins 5, wherein the upper flange 1 of high-strength bamboo laminated timber and the upper part of the high-strength bamboo laminated timber web 3 are connected through the card slot 4 and the shear-resistant bamboo screws and bamboo pins 5, high-strength The lower flange 2 of the bamboo glulam is connected with the lower part of the web 3 of the high-strength bamboo glulam through the card slot 4 and the shear-resistant bamboo screw and bamboo pin 5 .

[0049] The high-strength bamboo glulam refers to the tensile strength along the grain not less than 100MPa, the compressive strength along the grain not less than 50MPa, the modulus of elasticity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap