Prediction method for flowing bottomhole pressure of gas well

A technology of bottomhole flow pressure and prediction method, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc. It can solve the problem of gas well production, casing pressure and bottomhole flow pressure changes, the difficulty of gas well bottomhole flow pressure prediction, and the time-consuming actual measurement And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now the specific embodiment of the present invention in conjunction with accompanying drawing is described in the following.

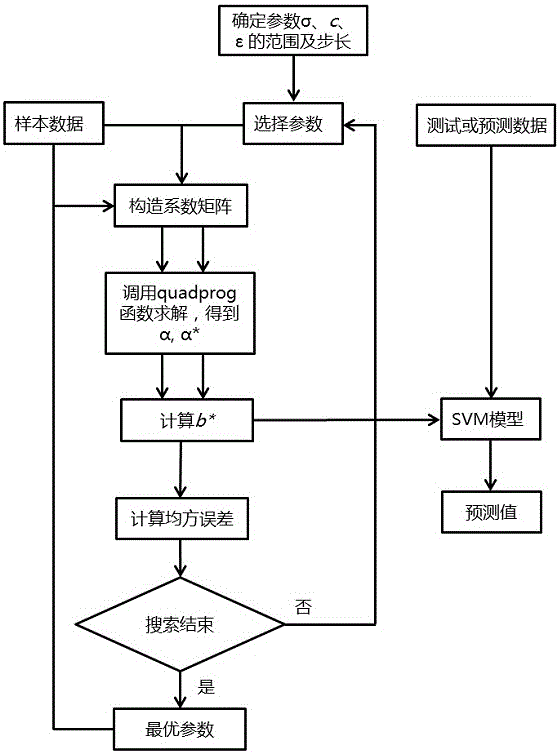

[0031] A method for predicting bottomhole flow pressure of a gas well in this embodiment, the prediction steps are as follows:

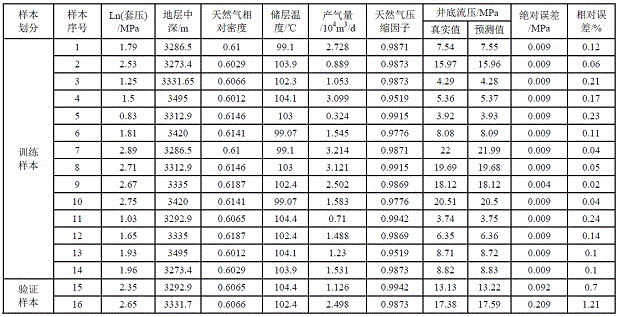

[0032] 1) Measure or collect the casing pressure, formation depth, relative density of natural gas, reservoir temperature, gas production, natural gas compression factor, and measured gas well bottomhole pressure parameters of a certain block. The specific methods include the following two aspects:

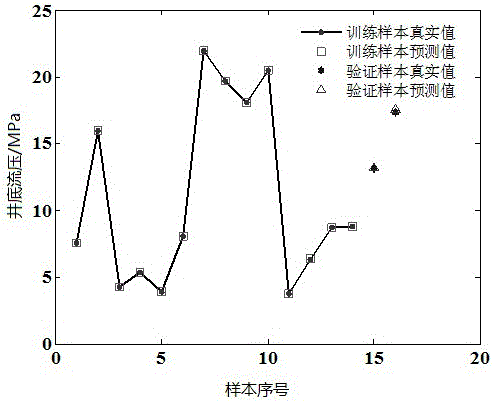

[0033] a Collect the existing production curves of the oilfield to obtain casing pressure and gas production parameters, see image 3 .

[0034] bCollect formation mid-depth parameters, reservoir temperature parameters, and measured well bottomhole flow pressure parameters, measure the relative density of natural gas with a balancer, and measure the compression factor of natural gas with a high-pressure physical property...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com