Check valve

A technology of check valve and valve body, which is applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of small flow, cannot meet the demand of system flow, and affect the service life of the valve, so as to achieve uniform utilization and loss, and improve Filtration efficiency, effect of reducing cleaning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

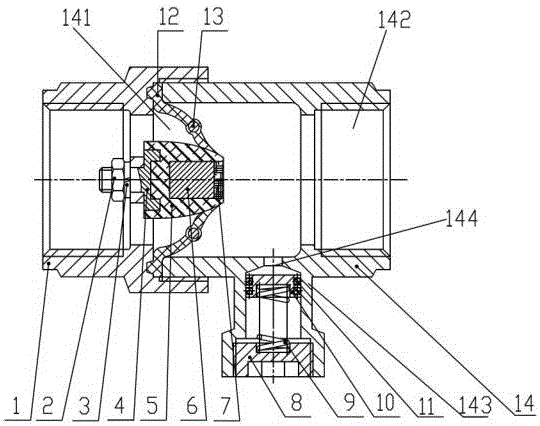

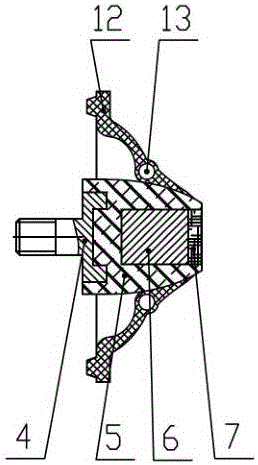

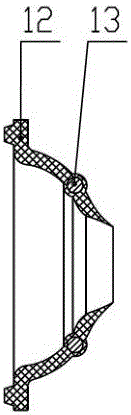

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1 to 5 , A check valve, including a valve body 14, a valve cover 1, and a check component fixed in the valve body 14. The valve 14 body is provided with a water inlet 141 and a water outlet 142, and the valve cover 1 is fixedly connected to the water inlet 141. The non-return component includes a flexible sheet 12 and a body 5, the body 5 gradually shrinks from the water inlet to the water outlet, the body 5 is embedded with a connecting shaft 4, and the connecting shaft 4 is fixedly connected to the valve cover 1 Specifically, the connecting shaft 4 is provided with an external thread, and the connecting shaft 4 passes through the valve cover 1 and is fixed by a nut 2 and an elastic washer 3. The connecting shaft 4 is a copper ridge, the body 5 is a plastic part, the copper material of the connecting shaft 4 can ensure the reliability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com