An industrial and commercial MW-level transcritical carbon dioxide heat pump oil separator

A carbon dioxide and oil separator technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigerators, etc., can solve the problems of ineffective separation and achieve the effect of simple and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

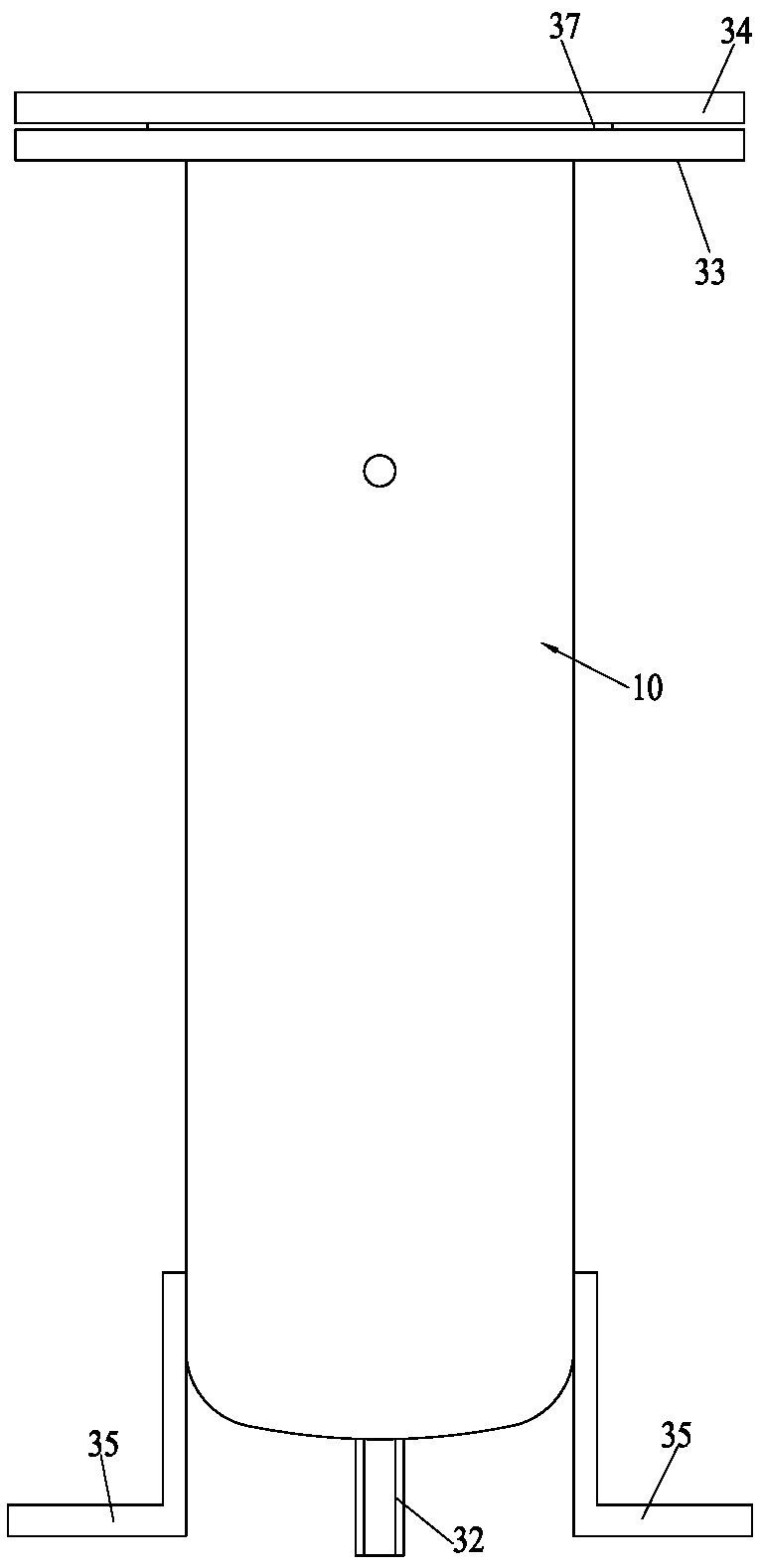

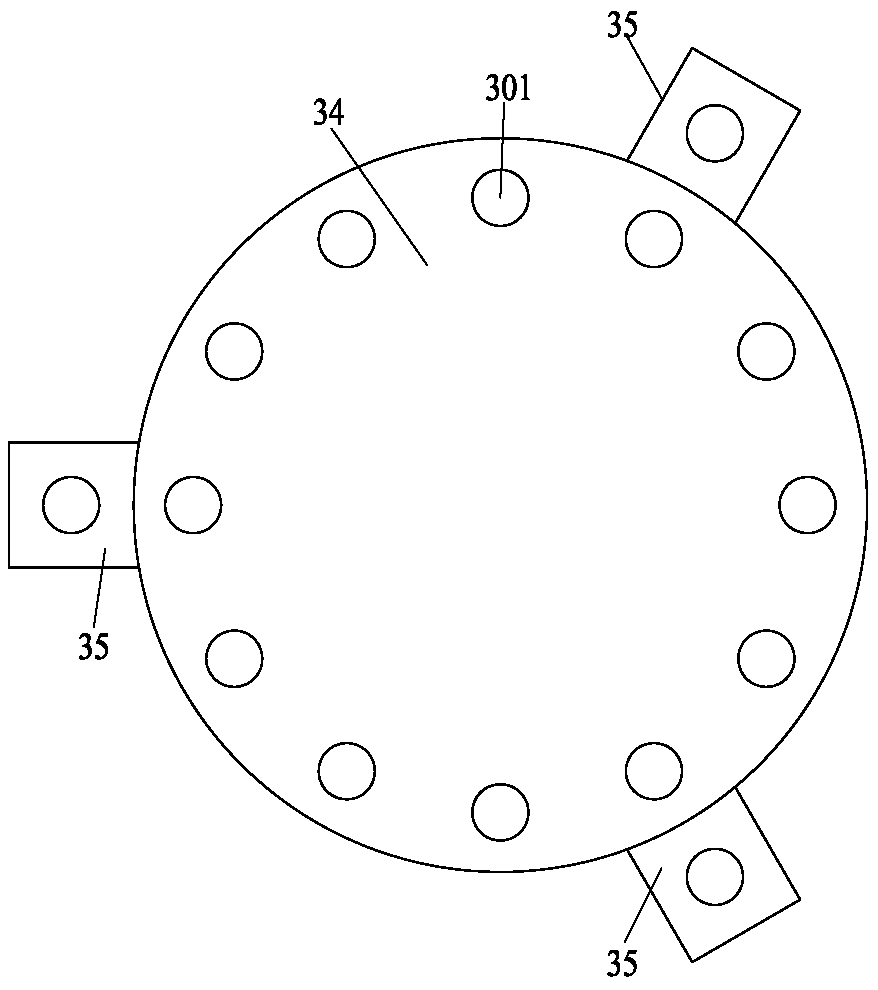

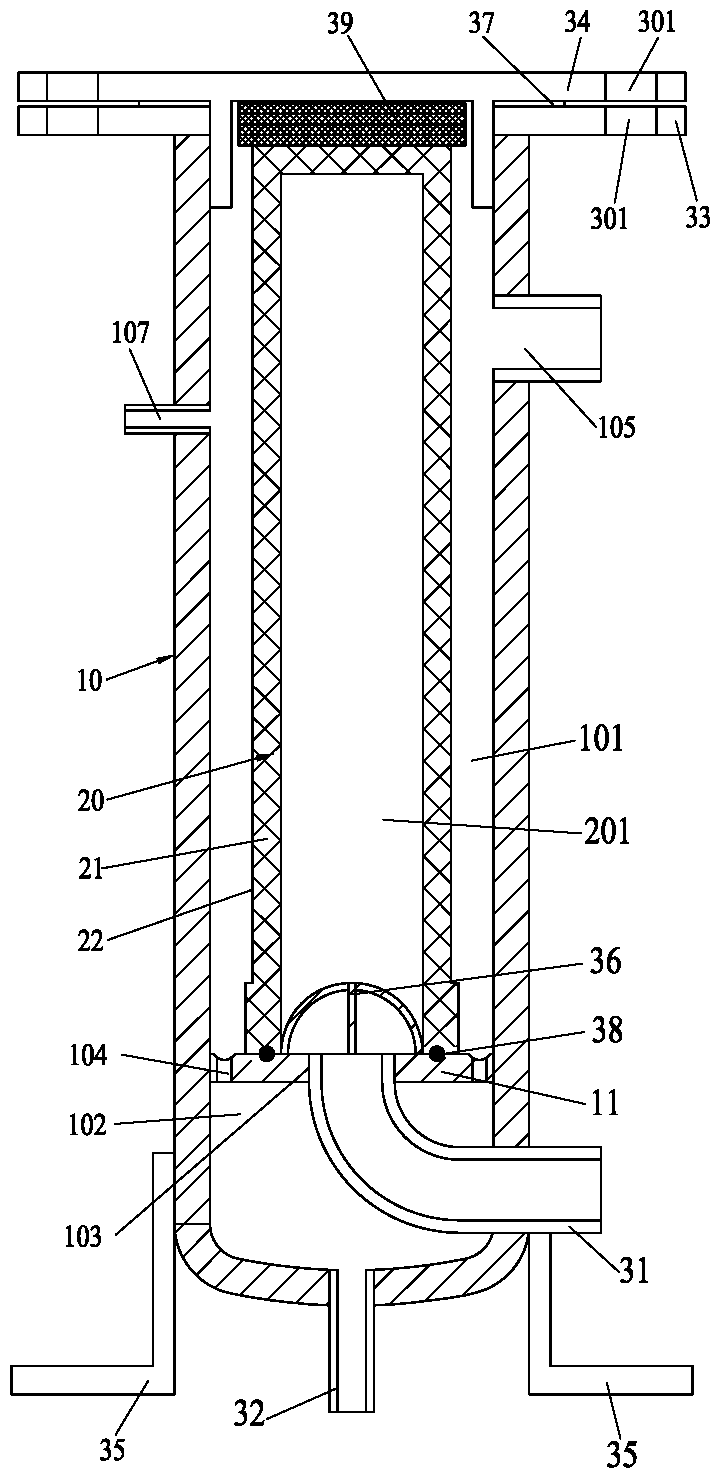

[0034] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including an outer shell 10 and an inner container 20 .

[0035] The lower end of the housing 10 is provided with a supporting platform 11, which divides the interior of the housing 10 to form an upper chamber 101 and a lower chamber 102, and the supporting platform 11 is provided with an air outlet 103 and a communication hole 104. The air outlet 103 is connected with an air outlet pipe 31, the air outlet pipe 31 passes through the lower chamber 102 and extends outwards from the lower end side of the casing 10, the bottom of the casing 10 is provided with an oil delivery pipe 32 communicating with the lower chamber 102, and the top of the casing 10 is provided with The lower flange 33 is sealed with an upper flange cover 34, and the upper side of the housing 10 is provided with an air inlet 105 communicating with the upper chamber 101; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com