Distributed optical fiber sensing system and operation method of dam wetting line in complex environment

A distributed optical fiber and complex environment technology, which is applied in the distributed optical fiber sensing system and operation field of dam infiltration line in complex environment, can solve the problems of poor anti-electromagnetic interference ability, lack of monitoring means and technology, short service life, etc., to achieve The effect of real-time perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

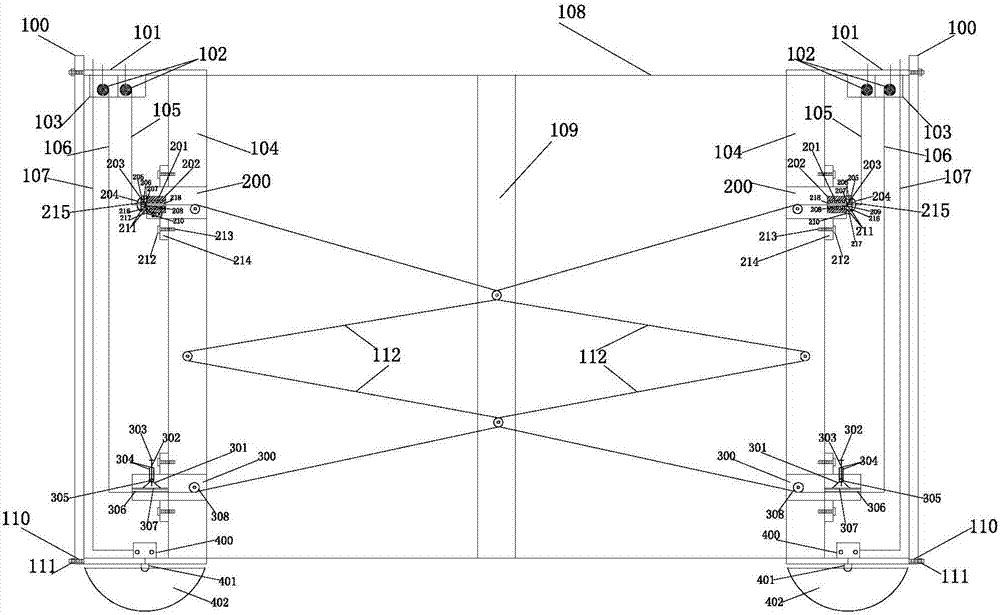

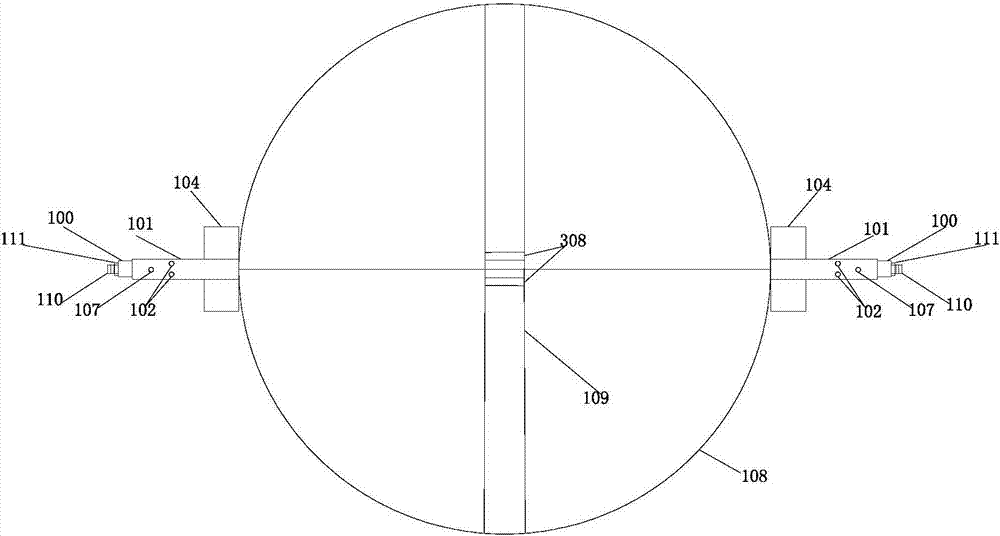

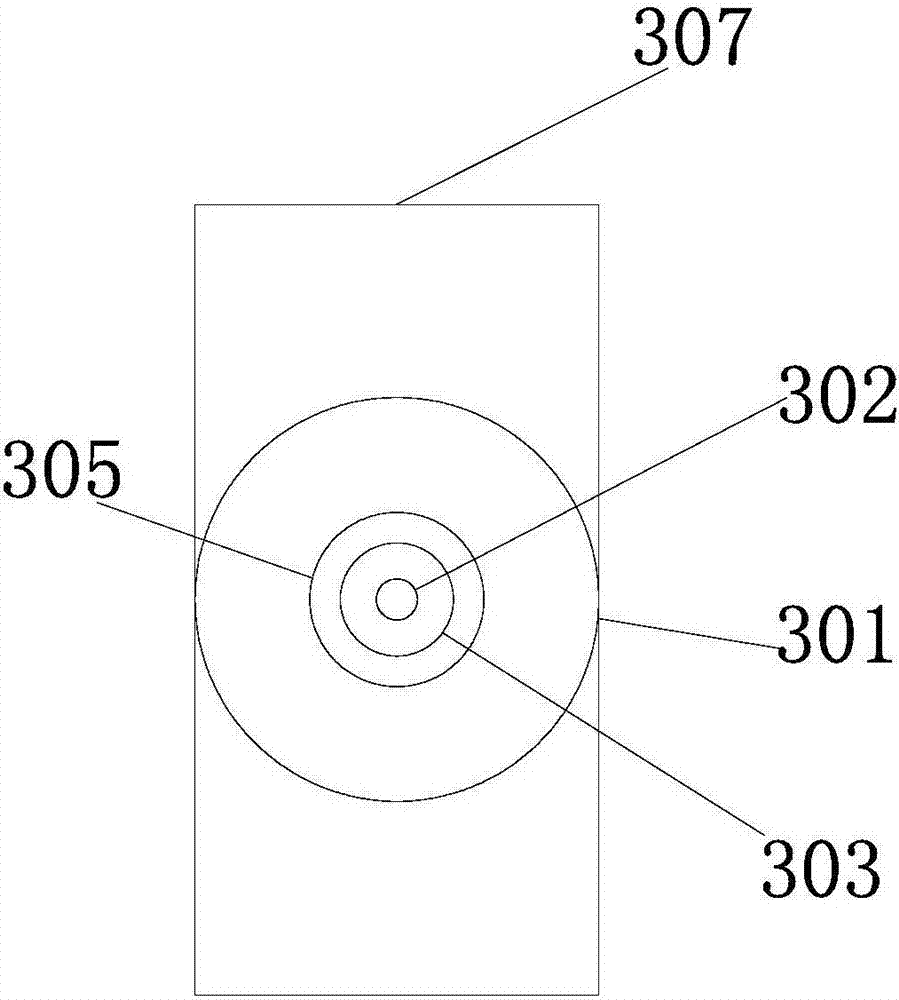

[0031] Such as Figure 1 to Figure 9 As shown, a distributed optical fiber sensing system for dam infiltration lines in a complex environment of the present invention includes a loading end connecting device, an inner frame body device, an output end connecting device, an outer matching body device, and a loading end connecting device The first port station 200 is connected to the inner frame device, the inner frame device is connected to the output terminal connecting device through the second port station 300, and the inner frame device is connected to the outer partner device through a transverse guide rod 101. The input guide device guides the input end 105 of the sensing fiber into the inner frame device. The sensing fiber is a ZTT-GYXTW-4A1a temperature measuring optical cable. The soil is sampled and analyzed in situ, and then the distributed perception of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com