Gradient piezoelectric ceramic intelligent cutting tool device with self-sensing cutting force

A technology of piezoelectric ceramics and cutting tools, applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., to achieve real-time perception, simple tool structure, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

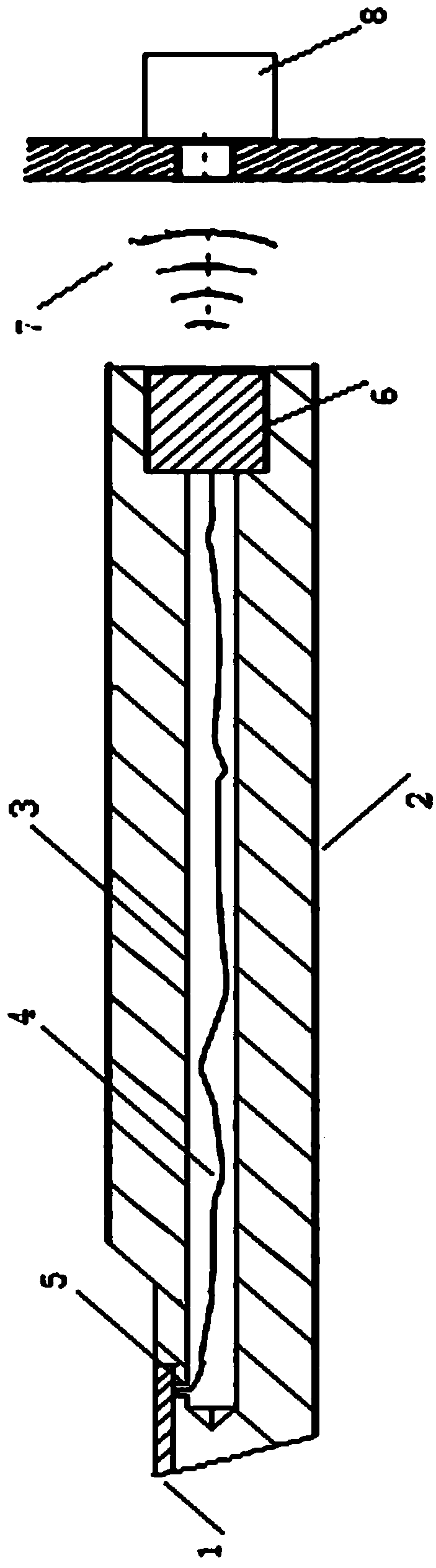

[0009] The gradient piezoelectric ceramic intelligent cutter with self-perception of cutting force of the present invention is fixedly installed on the processing machine tool. When cutting, the dynamic signal generated by the gradient piezoelectric ceramic blade 1 is transmitted to the signal amplification, A / D conversion and wireless transmission circuit integration module 6, the signal processed by signal amplification and A / D conversion is transmitted to signal receiving and processing system 8 through signal wireless transmission 7, and then transmitted to the single-chip microcomputer and host computer connected to it, and the host computer passes through Compensation, decoupling and other calculations are performed on the received data, and then the information of the cutting force in all directions is displayed on the display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com