A feeder waveguide penetration seal assembly

A technology of sealing components and waveguides, which is applied in the direction of sealing shells, electrical components, electrical equipment shells/cabinets/drawers, etc., can solve the problems of inability to achieve sealing effects, reduce efficiency, and take a long time to identify, so as to achieve self-position constancy , Improve the efficiency of maintenance and replacement, and ensure the effect of working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For ease of understanding, the specific structure and working process of the present invention are further described below in conjunction with the drawings:

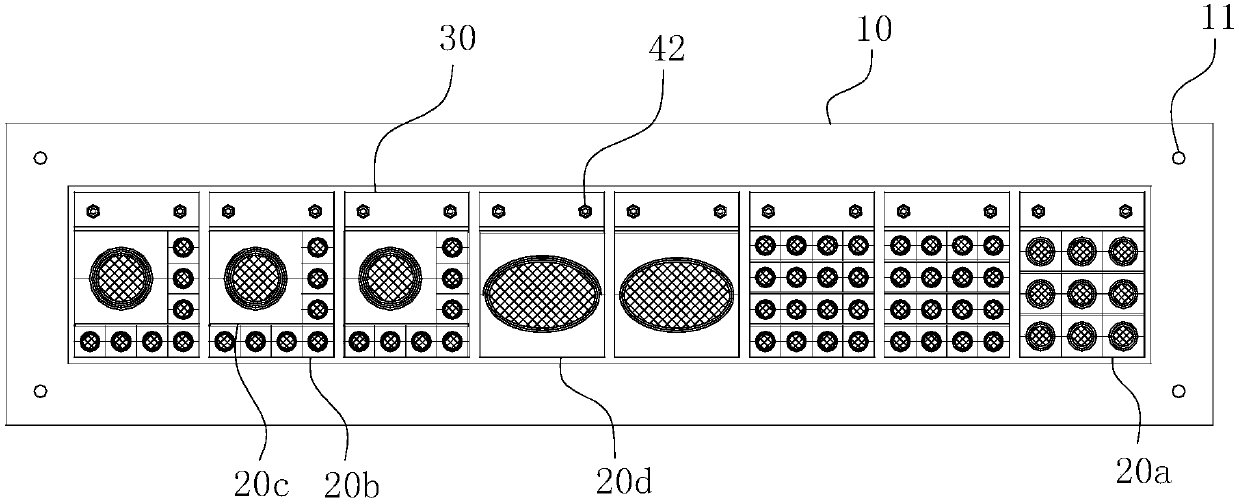

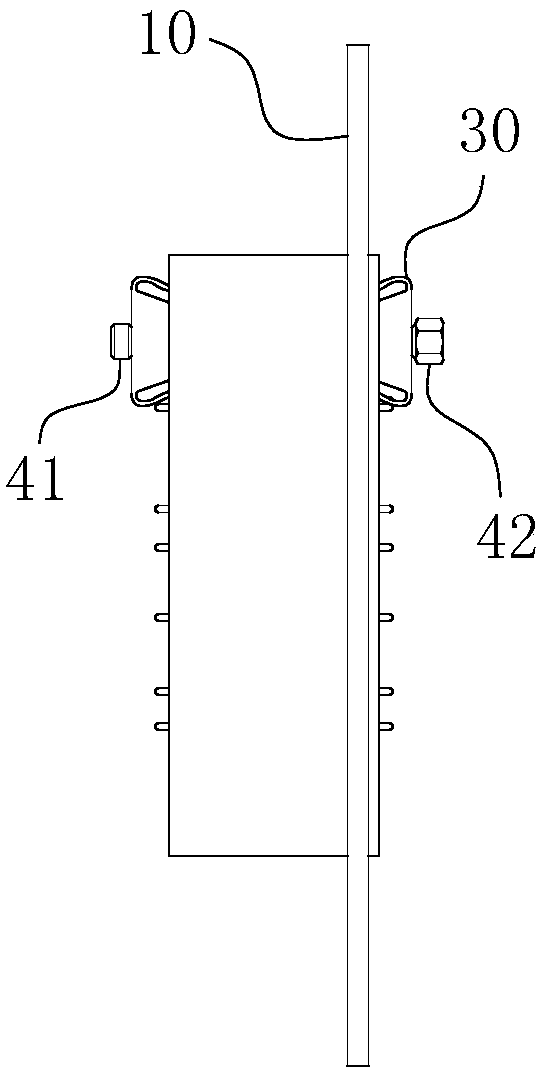

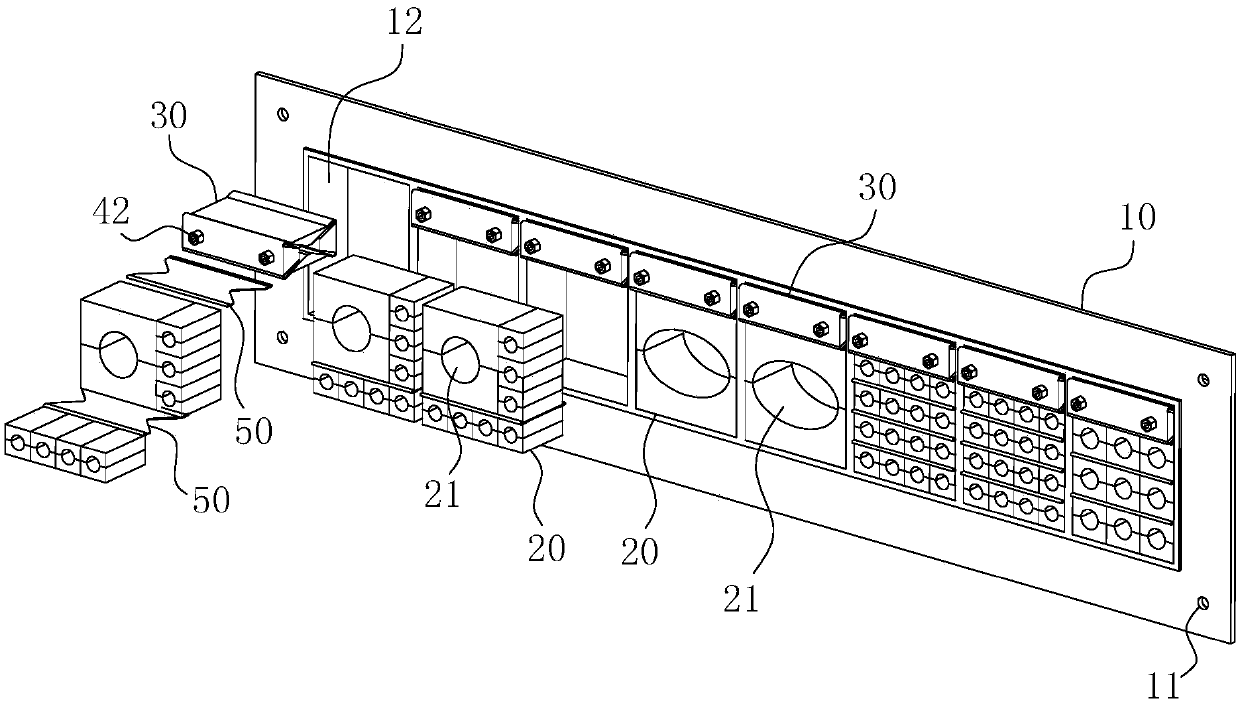

[0036]The specific structure of the present invention is shown in references 1-10, which includes a sealing frame 10 used as a component carrier. The sealing frame 10 is in the shape of a rectangular plate, and a square-hole-shaped fitting frame 12 is recessed through the surface of the plate. The fitting frame 12 has a certain hole depth, so as to fix and insert the filling body. The filling body includes a rubber sealing block 20 formed by overlapping and stacking a plurality of sub-modules in the shape of building blocks, and a tensioning block 30 for filling the gap between the rubber sealing block 20 and the fitting frame 12 . figure 1 , image 3 and Figure 9-10 The rubber sealing block 20 is composed of RM30 cable sealing sub-module 20a, RM40 cable sealing sub-module 20b, RM90 feeder sealing sub-module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com