Spiral grille dewatering machine

A technology of dehydrator and grid, which is applied in the direction of filtration and separation, membrane filter, fixed filter element filter, etc. It can solve the problems affecting the normal filtration of water, small filter seams, wear and other problems, and achieve high processing efficiency and space saving compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

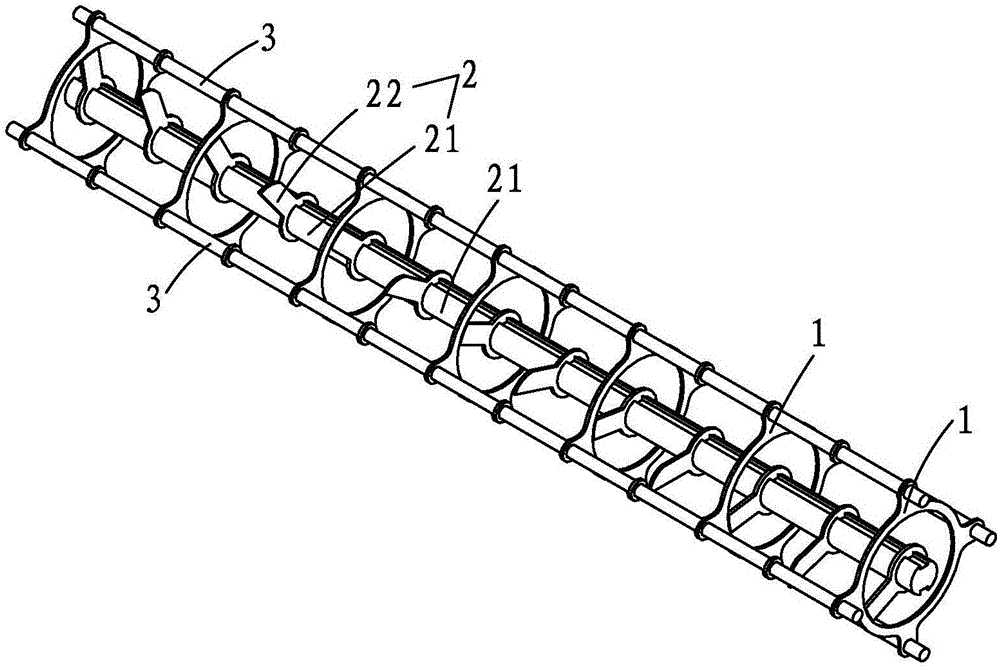

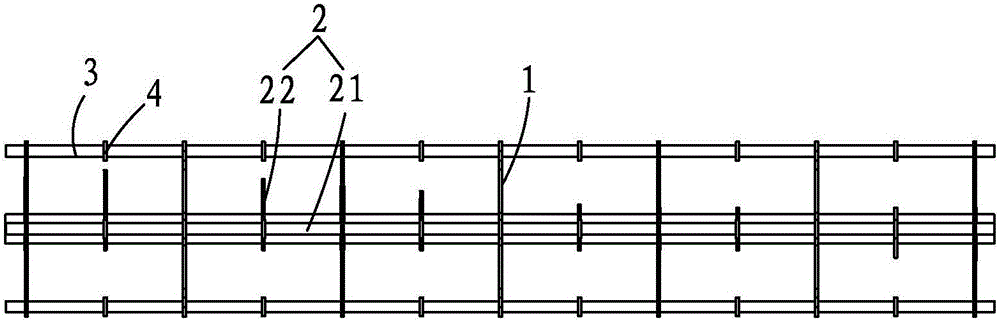

[0030] like Figure 1 to Figure 4 As shown, a spiral grill dehydrator includes a cavity formed by a plurality of adjacent fixed rings 1 and a screw shaft 2 passing through the cavity; the fixed ring 1 is circular, and the fixed ring The periphery of 1 is fixed by pillars 3, and spacers 4 are arranged on the pillars 3 to arrange the fixed rings 1 alternately and form filter seams; the spiral shaft 2 includes a central axis 21, a plurality of stacked rings perpendicular to the central axis The spiral blade formed by the shaft laminations 22; the shaft laminations 22 long-axis laminations at the corresponding positions of the filter seams formed between the fixed rings can be embedded and cleaned; the shaft laminations inside the stationary ring 1 It is a short-axis lamination, and its outer diameter is smaller than the inner diameter of the fixed ring 1.

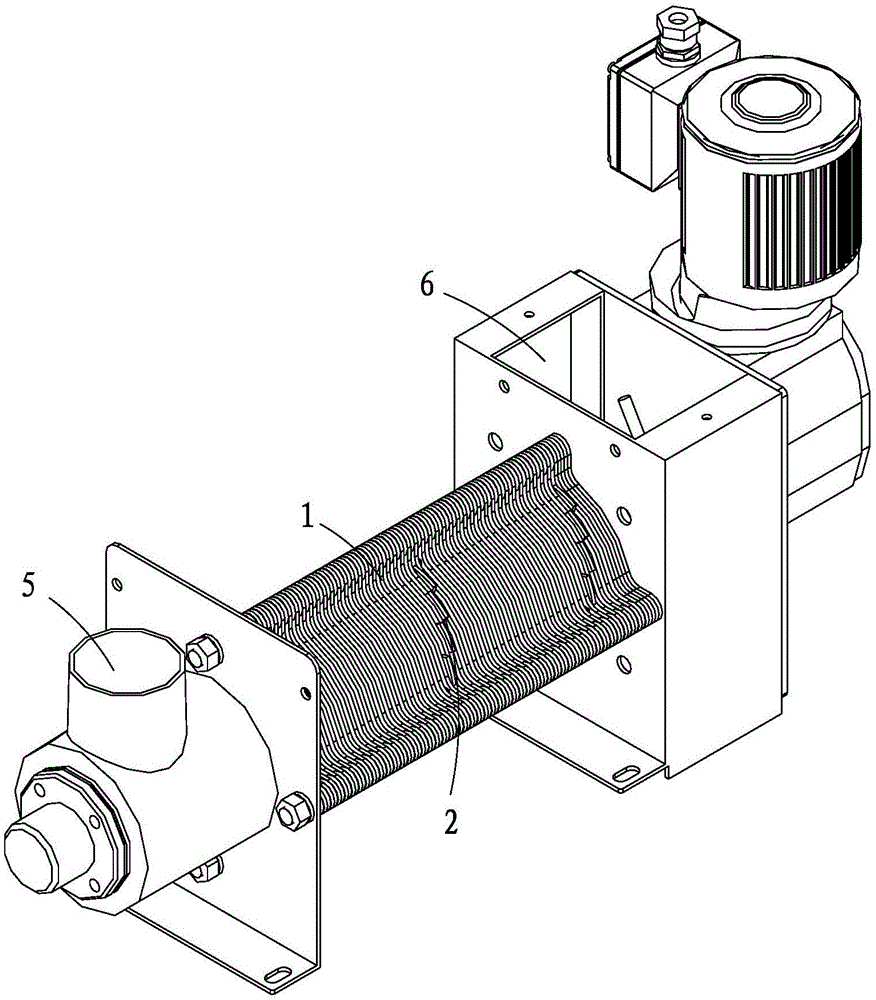

[0031] The two ends of the cavity are respectively provided with a feed port 5 and a discharge port 6 . An adjustable back...

no. 2 example

[0034] like Figure 5 and Image 6 As shown, the fixed ring 1 is elliptical, and the shortest outer radius and the longest inner radius of the ellipse are equal; Slightly larger; the radius of the minor axis laminations 22 located in the fixed ring 1 is smaller than the shortest inner radius of the ellipse of the fixed ring 1 .

no. 3 example

[0036] like Figure 7 and Figure 8 As shown, the screw shaft is a double-ended intermittent screw shaft, and the fixed ring 1 has an inner protruding structure 11 at the position corresponding to the discontinuity of the double-ended intermittent screw shaft, such as Figure 9 As shown, the inner protruding structure 11 in the successively stacked retaining rings 1 forms a wiper shaft protrusion.

[0037] In addition, the structure of the shaft laminations 22 can be adjusted according to the materials to be processed and the functions to be realized, such as Figure 10 Shown is a structural schematic diagram of a shaft lamination of the present invention. like Figure 11 Shown is a structural schematic diagram of another shaft lamination of the present invention.

[0038] The advantages of the present invention are: 1. The integrated design of grid solid-liquid separation and solid conveying and extrusion has compact space. 2. For materials that are not easy to run out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com