Novel glue blocking plate of roller glue spreader

A technology of glue baffle and gluing machine, which is applied in the direction of coating and liquid coating on the surface, etc. It can solve the problems of side leakage and waste of glue, difficult cleaning, and incomplete recovery of glue, and achieve the effect of reducing cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and example the present invention will be further described.

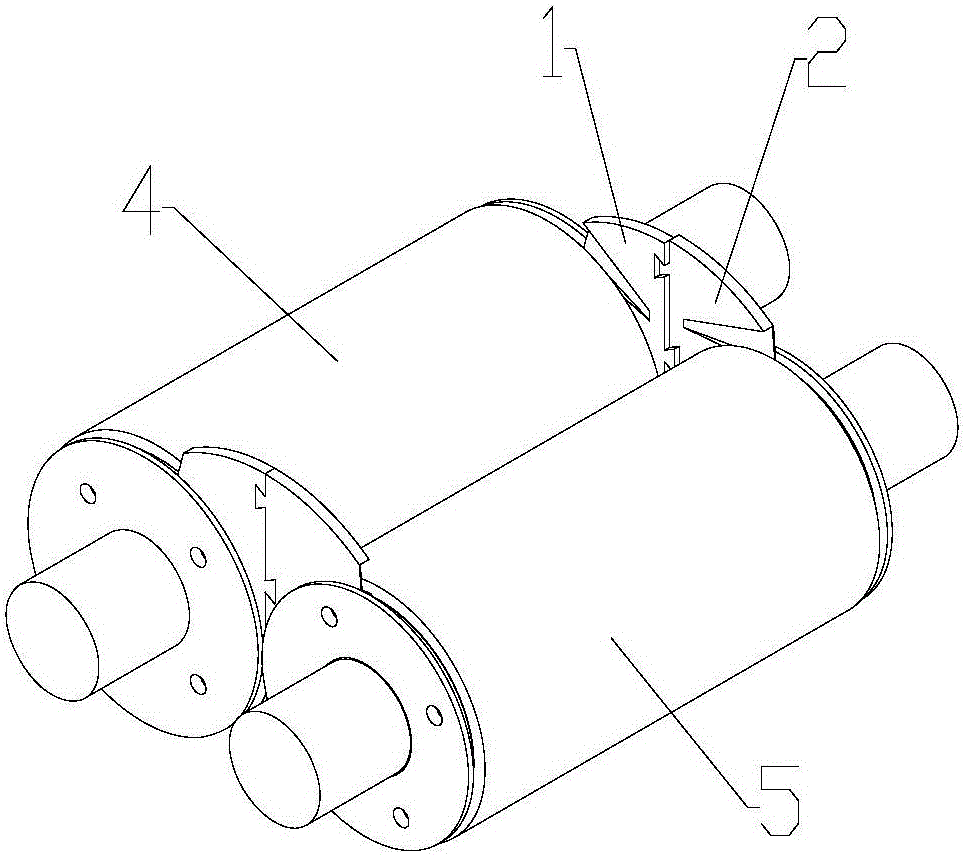

[0020] Such as Figure 1~4 as shown,

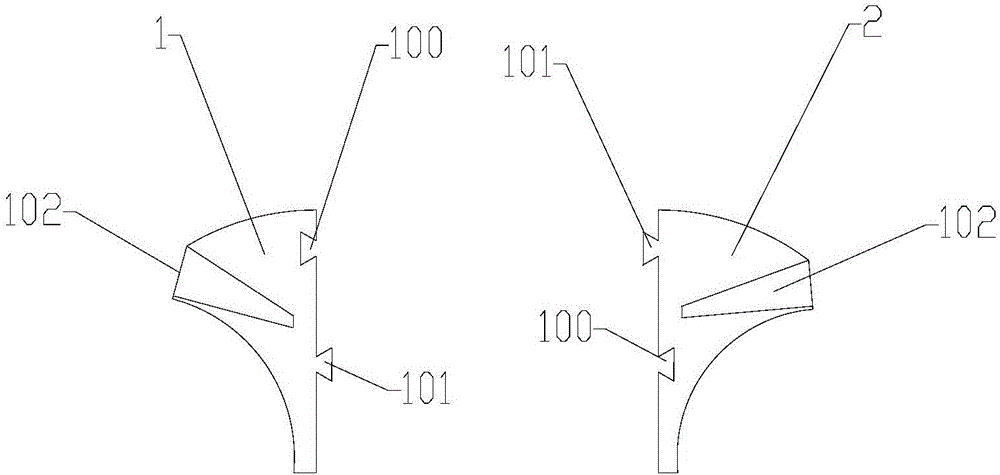

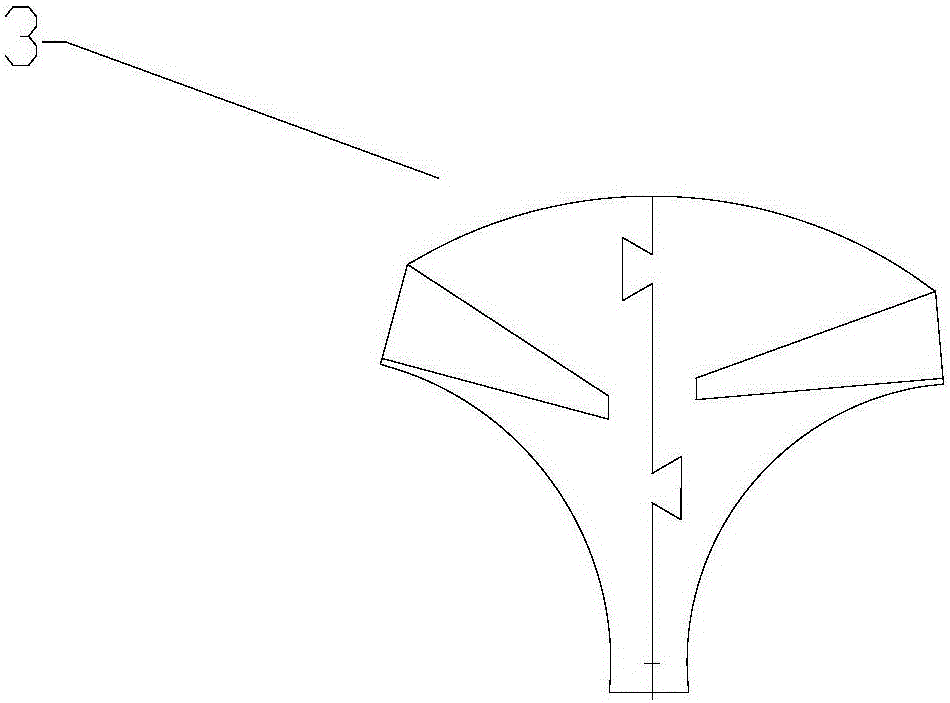

[0021] A new type of rubber baffle for a roller gluing machine, including a first rubber baffle 1 and a second rubber baffle 2, the first rubber baffle 1 is connected to the second rubber baffle 2, and the combination of the two The surfaces can be dislocated and connected; the first rubber baffle 1 and the second rubber baffle 2 are provided with arc-shaped edges that match the grooves of the rubber roller 4 and the rubber control roller 5; the first rubber baffle 1 1. The second rubber baffles 2 are respectively provided with diversion grooves 102 with one end open.

[0022] The joint surfaces of the first rubber baffle 1 and the second rubber baffle 2 are respectively provided with mutually matching bosses 101 and grooves, and the number of the bosses 101 corresponds to the number of grooves, which can be one or more. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com