Automatic liquid supply brush

An automatic liquid supply and brush technology, applied in the field of brushes, can solve the problems of wasting resources, polluting the working environment, and low efficiency, so as to ensure the quality of coating and reduce the cost of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

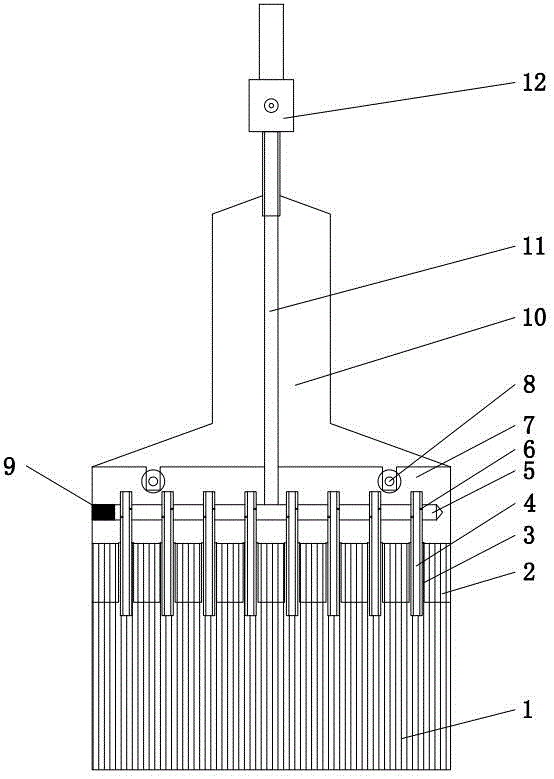

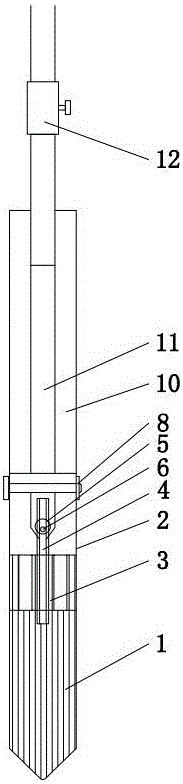

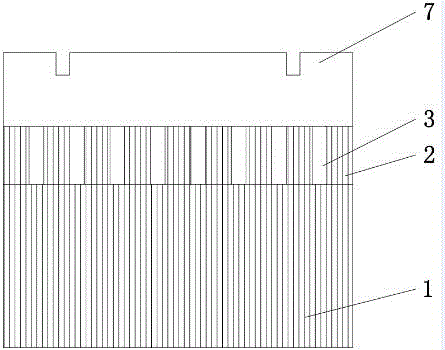

[0020] In order to describe in detail the technical content and structural features of the automatic liquid supply brush of the present invention, further description will be made below in conjunction with the embodiments and accompanying drawings.

[0021] Such as figure 1 As shown in .2.3.4.5.6, the present invention provides an automatic liquid supply brush, comprising bristles 1, iron hoop 2, liquid outlet pipe hole 3, liquid outlet pipe 4, liquid distribution pipe 5, liquid inlet hole 6. Brush head 7, clamping bolt nut 8, plug 9, handle 10, liquid delivery hole 11, flow switch 12, pressure tank 13, liquid coating tank 14, fixed seat 15, movable seat 16, compression bolt 17 , tank cover 18, O-ring 19, coating liquid 20, stirring shaft 21, pressure regulating valve 22, air inlet pipe 23, mixer assembly 24, liquid outlet pipe 25, air release valve 26, safety valve 27, filter screen 28, impeller 29. Fastening screw 30, pressure sleeve 31, sealing ring 32, installation sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com