Automatic flight surface cleaning robot for photovoltaic array

A photovoltaic array and surface cleaning technology, applied in the direction of cleaning methods using gas flow, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of high installation track cost, poor adaptability, and low degree of automation, so as to improve dust removal efficiency and reduce requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

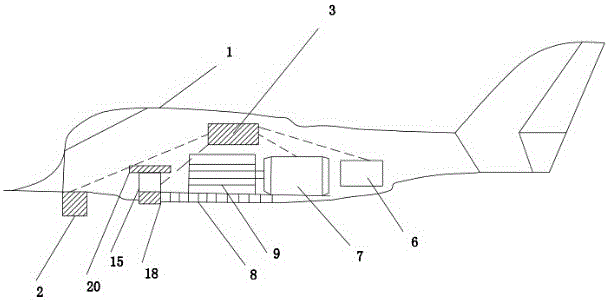

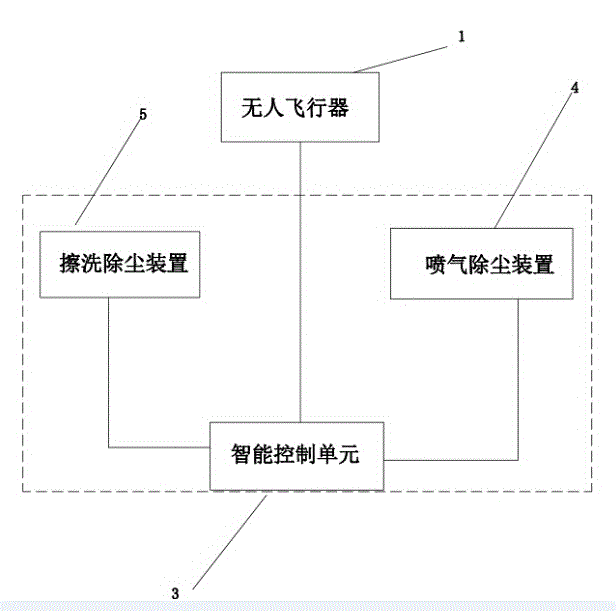

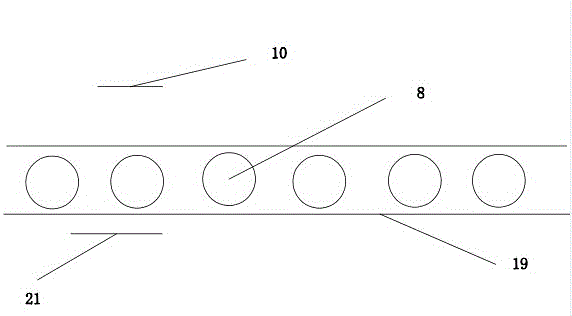

[0026] see as Figure 1-Figure 7 As shown, the technical solution adopted in this embodiment is: an automatic flying photovoltaic array surface cleaning robot, which includes an unmanned aerial vehicle 1, a high-definition camera 2, an intelligent control unit 3, a jet dust removal device 4, a scrubbing dust removal device 5 and a power supply 6 The high-definition camera 2 is arranged on the bottom of the front end of the unmanned aerial vehicle 1, an intelligent control unit 3 is installed on the top of the unmanned aerial vehicle 1, and a jet dust removal device 4 and a power supply 6 are installed on the bottom of the unmanned aerial vehicle 1 interior; the jet dust removal device 4 is powered by a DC motor 7 , an air pump 9 and an air nozzle 10; the DC motor 7 is connected to the power supply 6 and the air pump 9 respectively, and the air pump 9 is connected to an external pipeline 19, and the pipeline 19 is arranged on the brackets 21 on both sides of the unmanned aerial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com