Pneumatic cam chuck clamping mechanism

A cam chuck and clamping mechanism technology, applied in the direction of the chuck, etc., can solve the problems of complex structure of the jaw driving mechanism, small movable jaw stroke, inconvenient use and maintenance, etc., and achieve simple and reliable structure, firm clamping, automatic The effect of high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

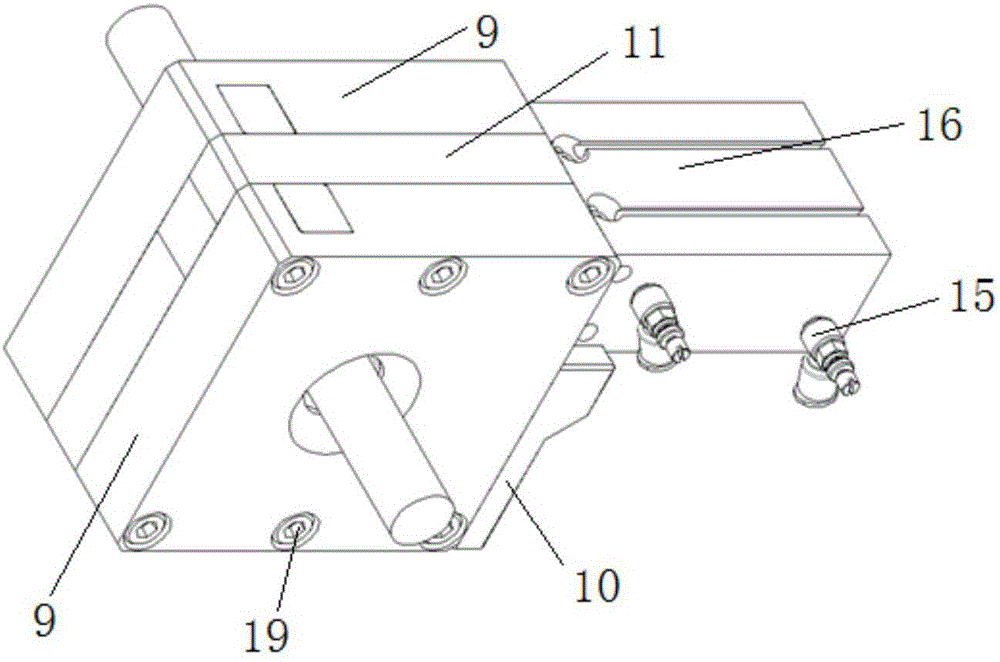

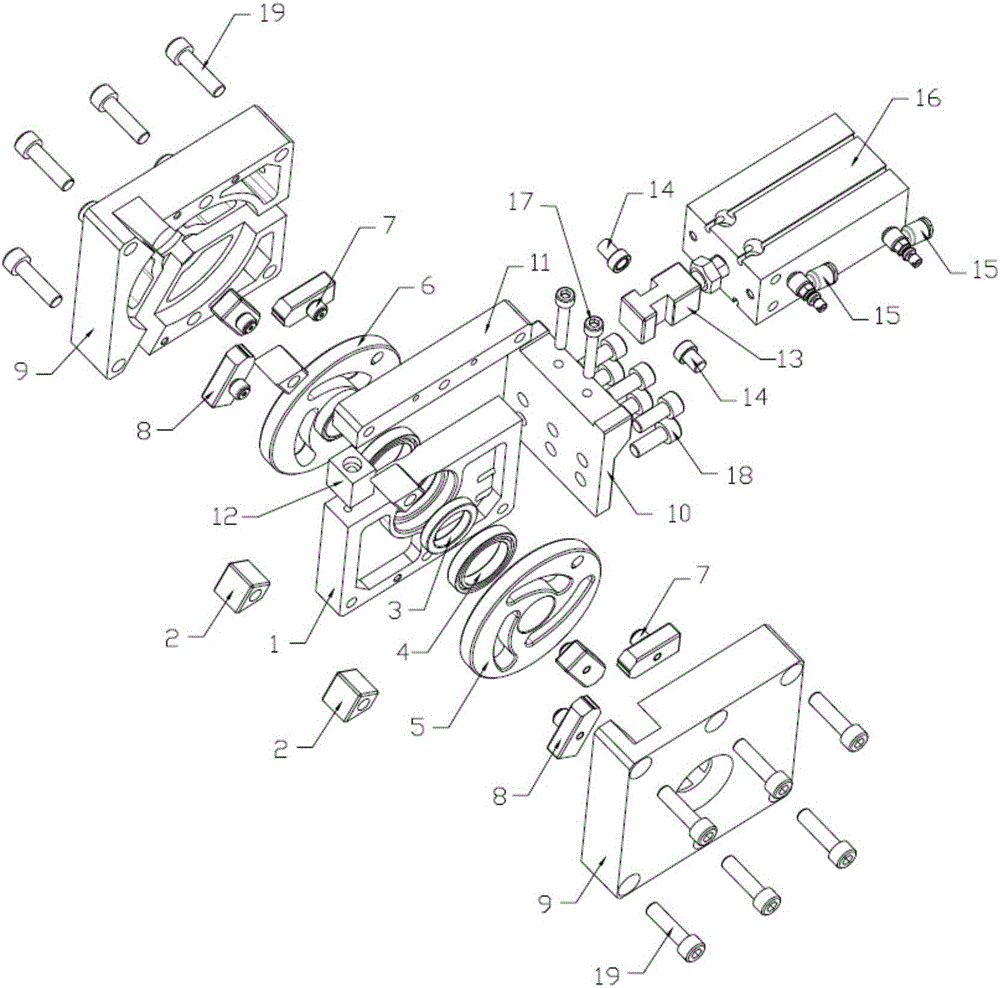

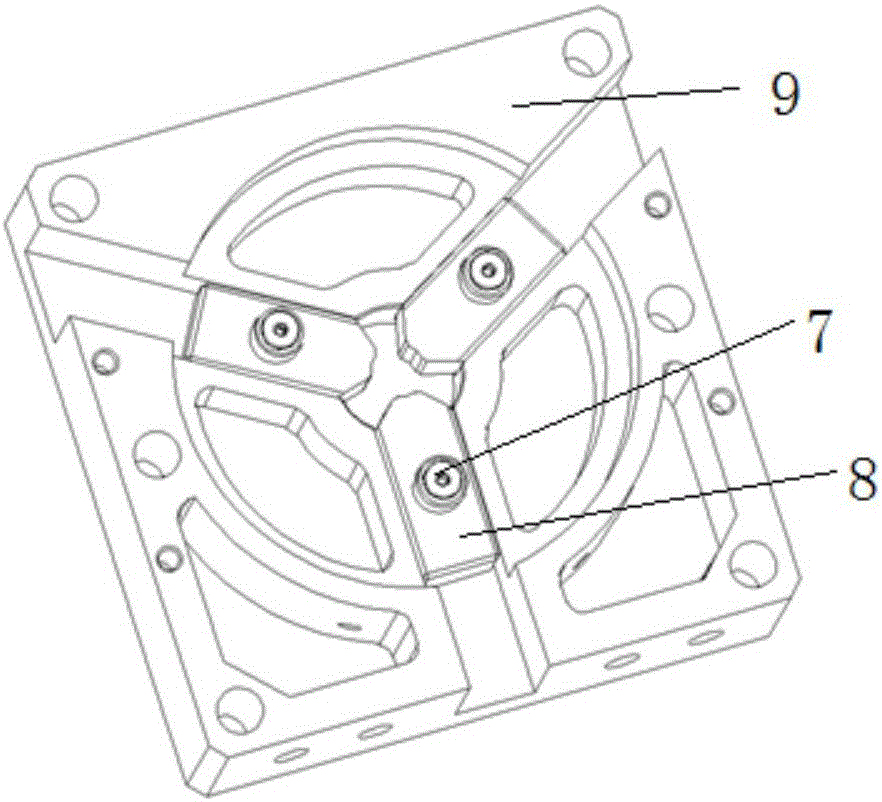

[0019] Such as Figure 1-Figure 5 As shown, a pneumatic cam chuck clamping mechanism includes a pneumatic assembly and a clamping body assembly. The overall structure of the clamping body assembly is square, and the pneumatic assembly is arranged on one side of the clamping body assembly. The pneumatic assembly includes a cylinder 16. The cylinder 16 is provided with a cylinder speed regulating valve 15 and an external pipeline. The clamping body assembly includes a chute plate 9 and a main body plate 1. The accommodation space is formed between the chute plate 9, the main body plate 1 and the splint 11. The cam The chuck is installed on the main body plate 1 through the ball bearing 4, and the high precision and low friction characteristics of the ball bearing 4 are used to ensure that the radial runout of the cam chuck is small during the rotation process, and the slider jaw 8 follows the cam through the cam. The actuator 7 is snapped into the cam chuck and can slide in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com