Weighing and transporting device

A transportation device and weighing technology, which is applied in the direction of transportation and packaging, conveyor control devices, conveyors, etc., can solve problems such as inaccurate weighing data, center of gravity biased to one side, unstable center of gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

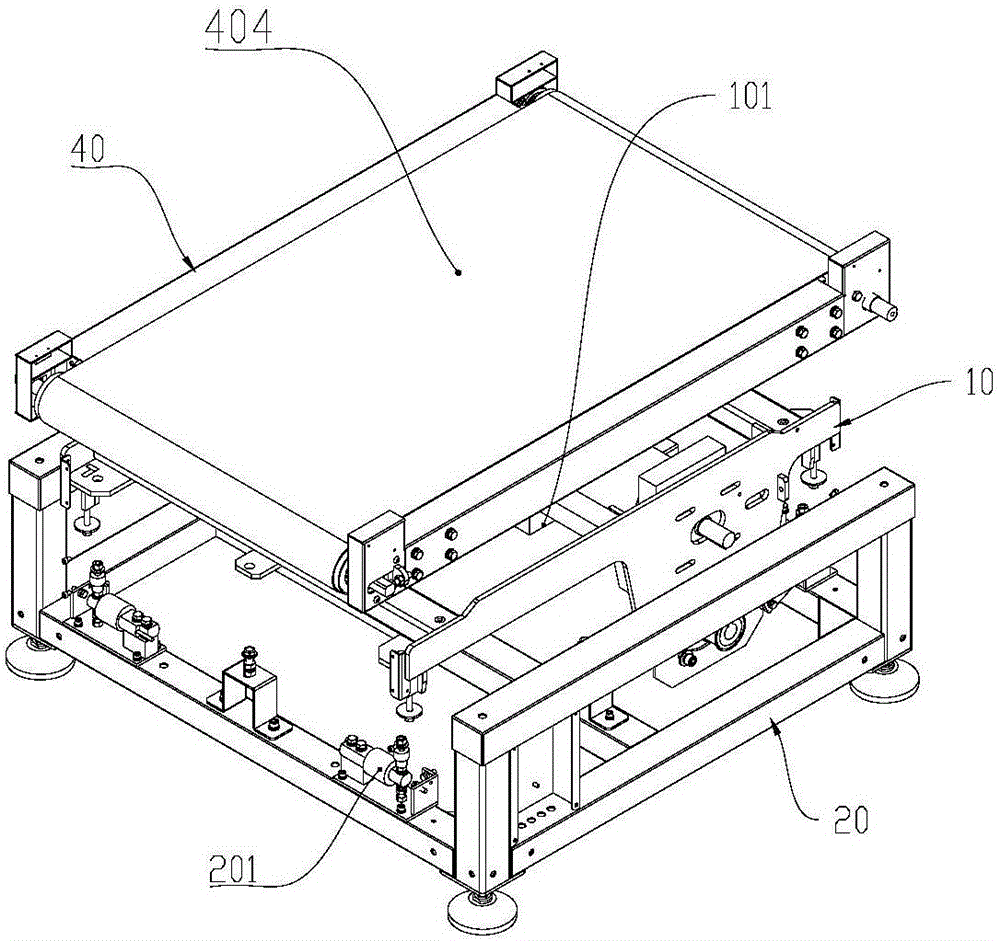

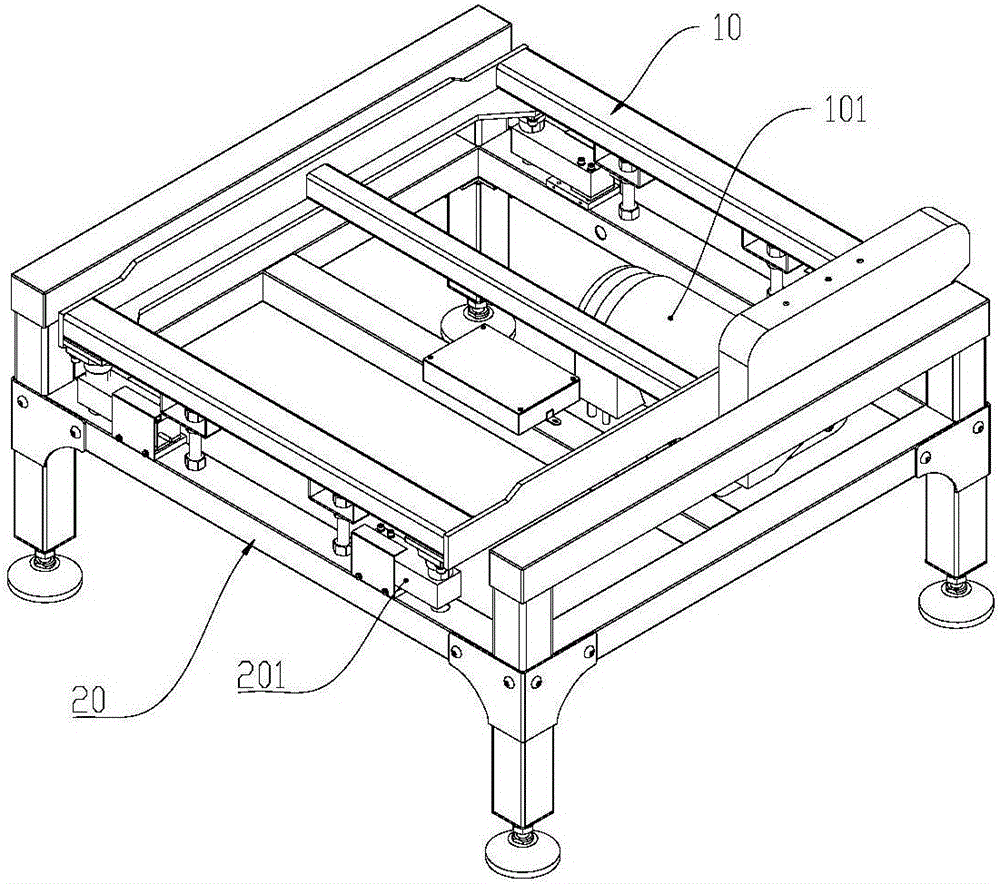

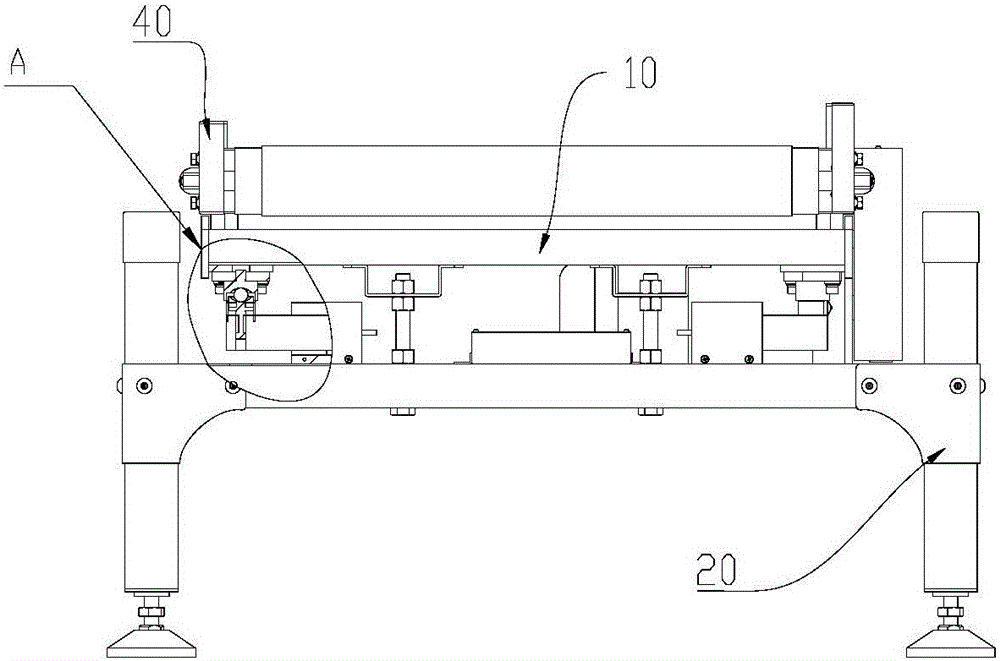

[0021] The first embodiment, such as Figure 1 to Figure 4 Shown, a kind of weighing and transporting device comprises top-level support 40, middle-level support 10 and bottom-level support 20 that are fixedly connected with top-level support 40; The driver 101 that drives the movement of the transmission belt 404, the bottom bracket 20 is fixed with a load cell 201 and an automatic centering assembly 30 fixedly connected with the load cell 201; the automatic centering assembly 30 includes a lower support column fixedly connected with the load cell 201 301, the upper support column 302 fixedly connected with the middle bracket and the steel ball 303 between the lower support column 301 and the upper support column 302; The upper receiving hole 305 of the steel ball 303 , the steel ball 303 is located in the lower receiving hole 304 and the upper receiving hole 305 and freely rotates in the lower receiving hole 304 and the upper receiving hole 305 .

[0022] Specifically, the ...

no. 2 example

[0025] The second embodiment, the difference between this embodiment and the first embodiment is that: the lower support column is provided with a second accommodation groove for accommodating the upper support column, and the bottom of the upper support column is sleeved in the second accommodation groove.

[0026] In other examples, such as Figure 5 with Image 6 As shown, the weighing transport device also includes a first roller assembly 70, a second roller assembly 50 and an adjustment assembly 60; the first roller assembly 70 and the second roller assembly 50 are connected by a transmission belt 404, and the top support 40 is provided with two parallel Side plate 401, one end of side plate 401 is respectively provided with horizontal chute 402, the other end of side plate 401 is provided with support hole 403, and first roller assembly 70 comprises first roller 703 and first roller shaft 701, the first roller shaft The two ends of 701 extend to the support holes 403 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com