Solid hot material quantitative charging system and control method thereof

A material and solid technology, applied in the quantitative feeding system of solid hot materials and its control field, can solve the problems of energy waste, heat waste, etc., and achieve the effect of omitting energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme of the present invention will be apparent through the detailed description of the specific embodiments of the present invention below in conjunction with the accompanying drawings.

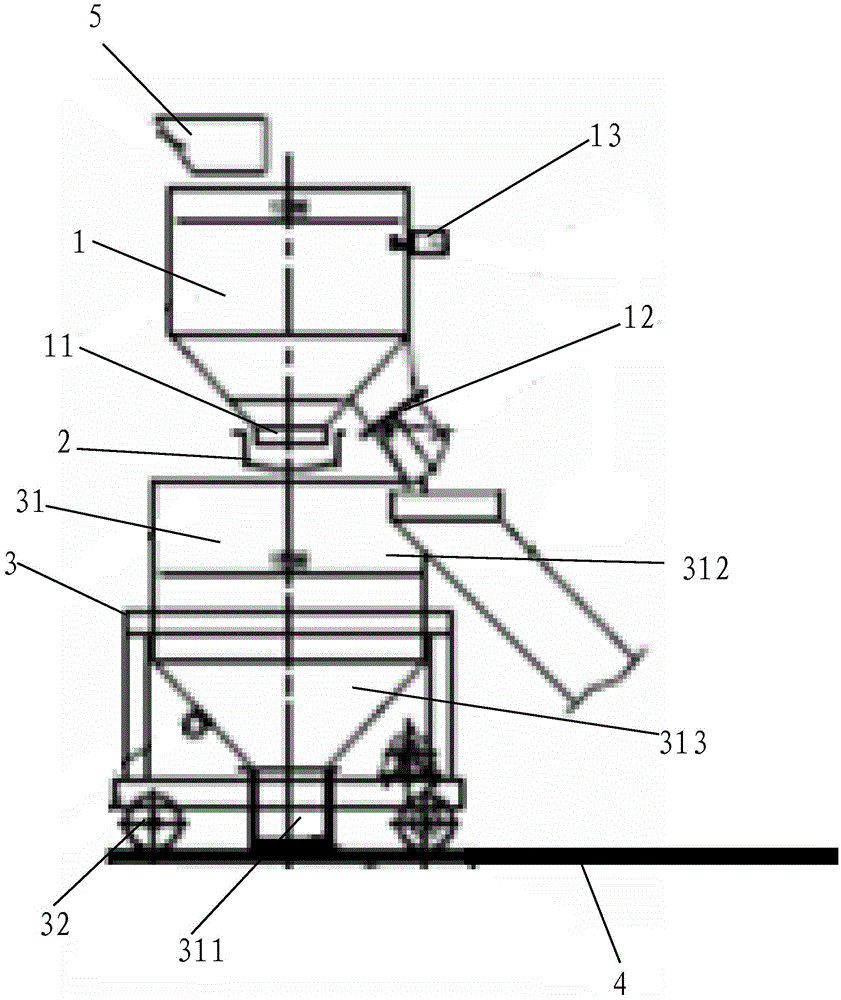

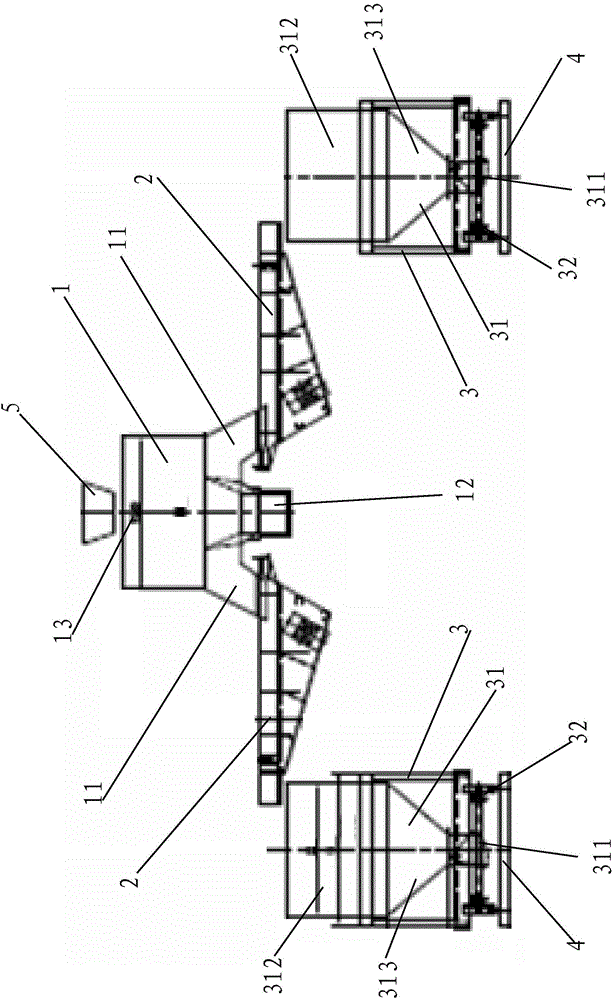

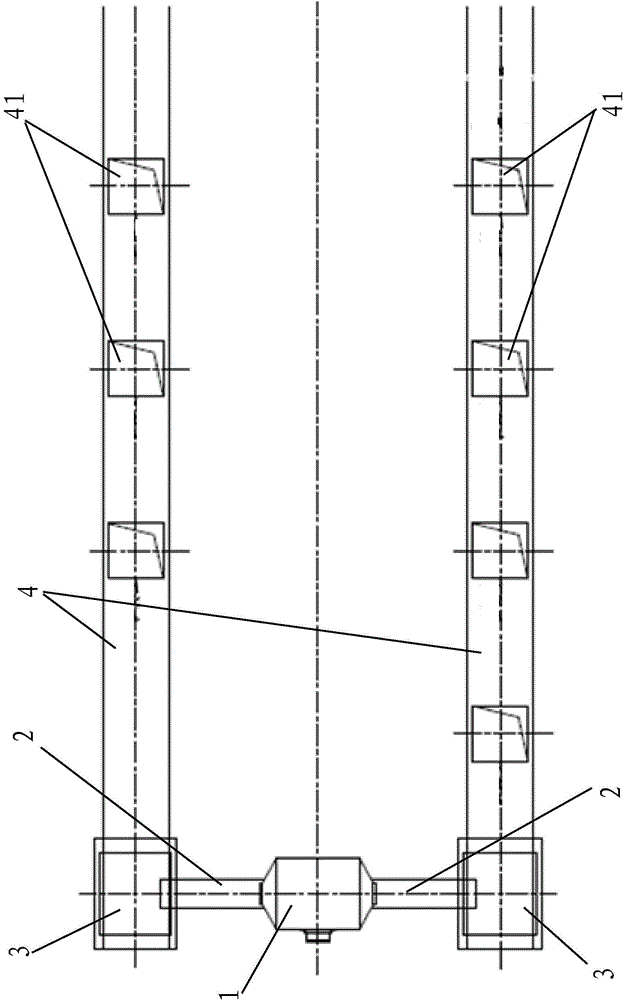

[0037] Such as Figure 1-3 As shown, the present invention firstly provides a quantitative feeding system for solid hot materials (such as cullet with high temperature), which includes a buffer hopper 1, a feeder 2, a feeding trolley 3 and a track scale 4 connected in sequence.

[0038] The buffer hopper 1 is arranged below the material delivery inlet 5, such as the end of the chain conveyor, and is used for accepting materials to be delivered. The bottom of the buffer hopper 1 is provided with a material outlet 11 , and the material outlet 11 is connected to the material inlet of the feeder 2 . The feeding trolley 3 is provided with a storage hopper 31 inside, and the bottom of the feeding trolley 3 is provided with a traveling wheel 32, and the traveling wheel 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com