Temperature control system of infrared heating ironing roller

A temperature control system and technology for ironing rollers, which are applied in textile and papermaking, fabric surface trimming, etc., can solve the problems of high energy consumption, high energy consumption, and no oil boiler heating system for electric heating ironing rollers, and save energy. The effect of high-power electricity consumption, accelerated heating process, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

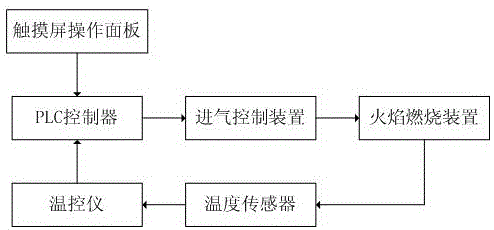

[0020] Such as figure 1 as shown in figure 1 As shown, an infrared heating ironing roller temperature control system includes a flame combustion device, a temperature sensor, a temperature controller, a PLC controller, an air intake control device and a touch screen operation panel; the PLC controller is connected with the temperature controller respectively. The output end, the control end of the air intake control device, and the output end of the touch screen operation panel are connected, and the input end of the temperature controller is connected with the temperature sensor; the temperature sensor is set on one side of the flame combustion device, and the air intake control device is set On the gas supply pipeline of the flame combustion device; wherein, the air intake control device adopts an air intake control solenoid valve.

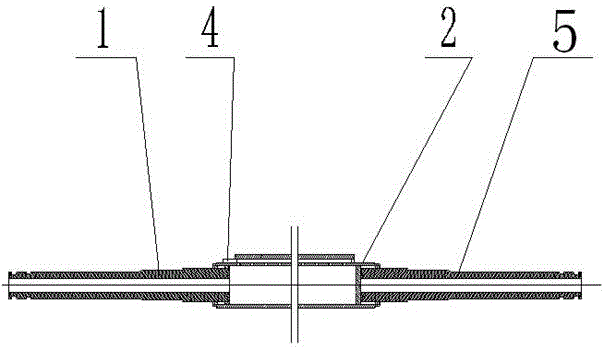

[0021] Such as figure 2 As shown, the flame combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft hea...

Embodiment 2

[0023] Such as figure 1 As shown, an infrared heating ironing roller temperature control system includes a flame combustion device, a temperature sensor, a temperature controller, a PLC controller, an air intake control device and a touch screen operation panel; the PLC controller is connected with the temperature controller respectively. The output end, the control end of the air intake control device, and the output end of the touch screen operation panel are connected, and the input end of the temperature controller is connected with the temperature sensor; the temperature sensor is set on one side of the flame combustion device, and the air intake control device is set On the gas supply pipeline of the flame combustion device; wherein, the air intake control device adopts an air intake control solenoid valve.

[0024] Such as figure 2 As shown, the flame combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft head 5; one end of the le...

Embodiment 3

[0026] Such as figure 1 As shown, an infrared heating ironing roller temperature control system includes a flame combustion device, a temperature sensor, a temperature controller, a PLC controller, an air intake control device and a touch screen operation panel; the PLC controller is connected with the temperature controller respectively. The output end, the control end of the air intake control device, and the output end of the touch screen operation panel are connected, and the input end of the temperature controller is connected with the temperature sensor; the temperature sensor is set on one side of the flame combustion device, and the air intake control device is set On the gas supply pipeline of the flame combustion device; wherein, the air intake control device adopts an air intake control solenoid valve.

[0027] Such as figure 2 As shown, the flame combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft head 5; one end of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com