Steel structure toilet

A toilet and steel structure technology, applied in the field of the whole toilet, can solve the problems of increasing the workload of installation and maintenance personnel, waste of installation materials, secondary damage, etc., to avoid unevenness of the bottom layer, save manpower and material resources, and ensure the effect of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

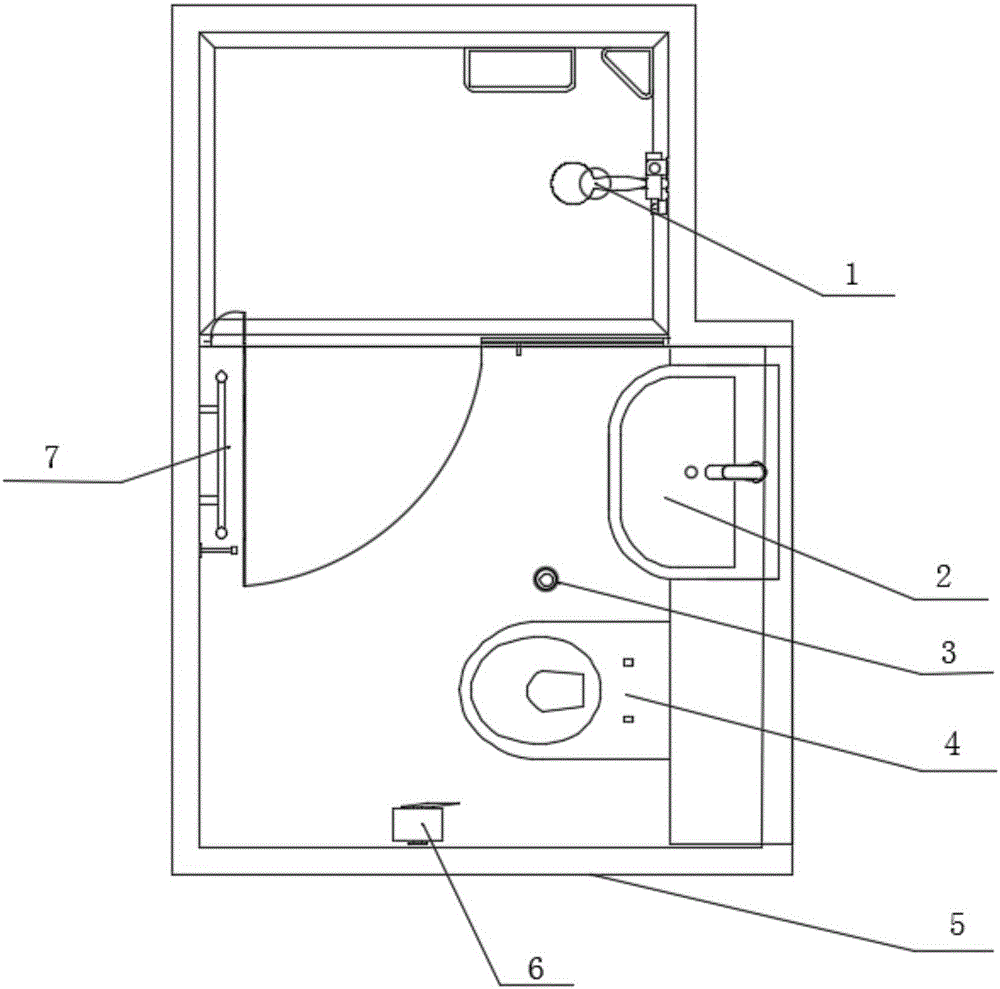

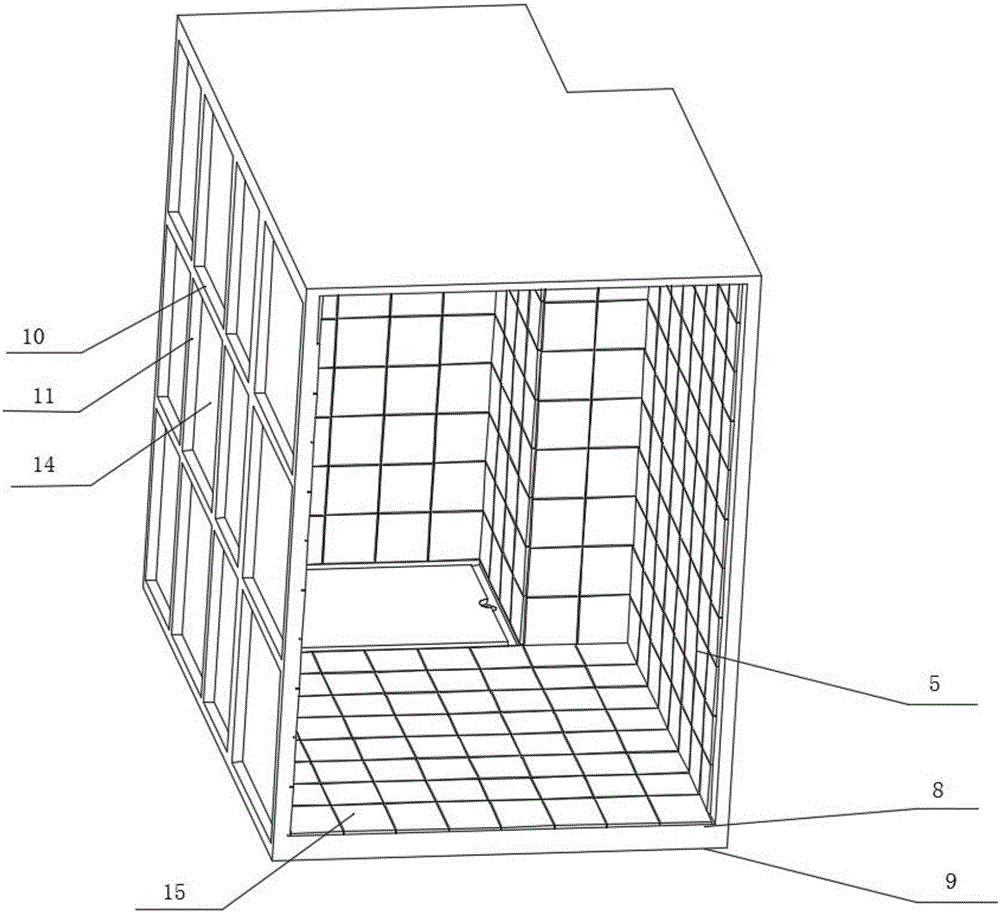

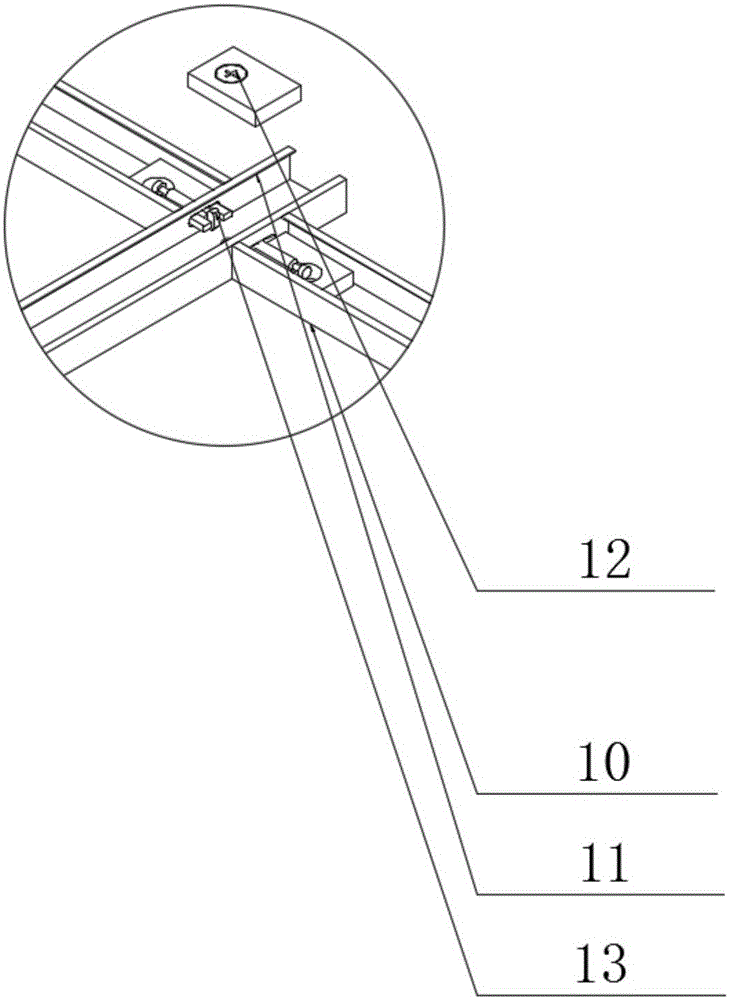

[0015] Embodiment 1: said a kind of steel structure restroom, comprises washing table 2, dresser 7, illuminating lamp 3, toilet paper holder 6, nozzle 1, support structure 5, plate 14, flush toilet 4, floor 15, it is characterized in that: all The support structure 5 of a steel structure bathroom adopts an integrated all-steel structure. The main keel 11 and the auxiliary keel 10 of the support structure 5 are coupled and locked by the rotary latch 13 and the knob lock 12. The plate 14 is equipped with a hanging buckle. system, the plate 14 is directly hung and buckled on the support structure, the floor 15 is equipped with a horizontal support device, and the floor 15 is directly hung and buckled on the support structure. The board 14 and the floor 15 adopt an inorganic decorative integrated board, which has the characteristics of light weight, wear resistance and fire resistance, which not only reduces the workload of the installers, but also ensures the quality effect of the...

Embodiment 2

[0016] Embodiment 2: said a kind of steel toilet, comprises washing table 2, dresser 7, lighting lamp 3, toilet paper holder 6, sprinkler head 1, support structure 5, plate 14, flush toilet 4, floor 15, described a kind of steel The supporting structure 5 of the bathroom adopts an integrated all-steel structure. The main keel 11 and the auxiliary keel 10 of the supporting structure 5 are coupled and locked by the rotary latch 13 and the knob lock 12. The plate 14 is equipped with a hook system, and the plate 14 The floor 15 is directly hung and buckled on the support structure, and the floor 15 is equipped with a horizontal support device, and the floor 15 is directly hung and buckled on the support structure. The board 14 and the floor 15 adopt an inorganic decorative integrated board, which has the characteristics of light weight, wear resistance and fire resistance, which not only reduces the workload of the installers, but also ensures the quality effect of the steel struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com