Water pump control system and control method for preventing rusting and blocking and realizing small-flow work

A control system and control method technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve problems such as shortening the service life of the motor, service life, and rust quality, so as to improve efficiency and reduce costs. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The parameters of this embodiment are: 1. The rated pressure of the first pressure gauge (101) is the pressure value in the pump (200) of the rust card, and the value is written according to the model of the water pump (200); 2. The anti-rust card 3. The marked pressure of the second pressure gauge (102) refers to the normal pressure value without flow, which is programmed according to the model of the water pump (200); 4. The preset time for small flow control Set the time to 5 seconds. And the anti-rust card module and the small flow automatic detection control module of this embodiment operate as independent control modules. Its specific implementation is as follows:

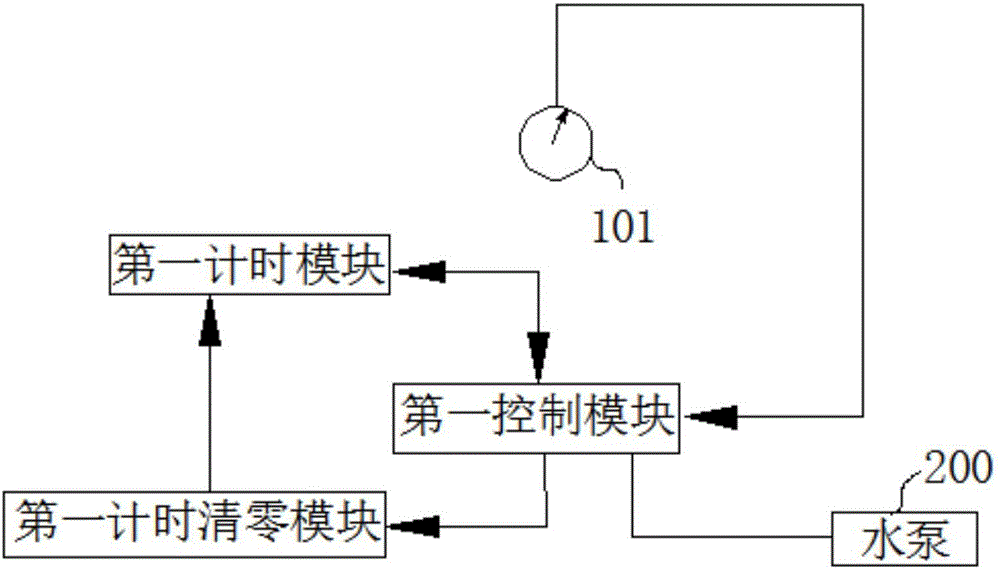

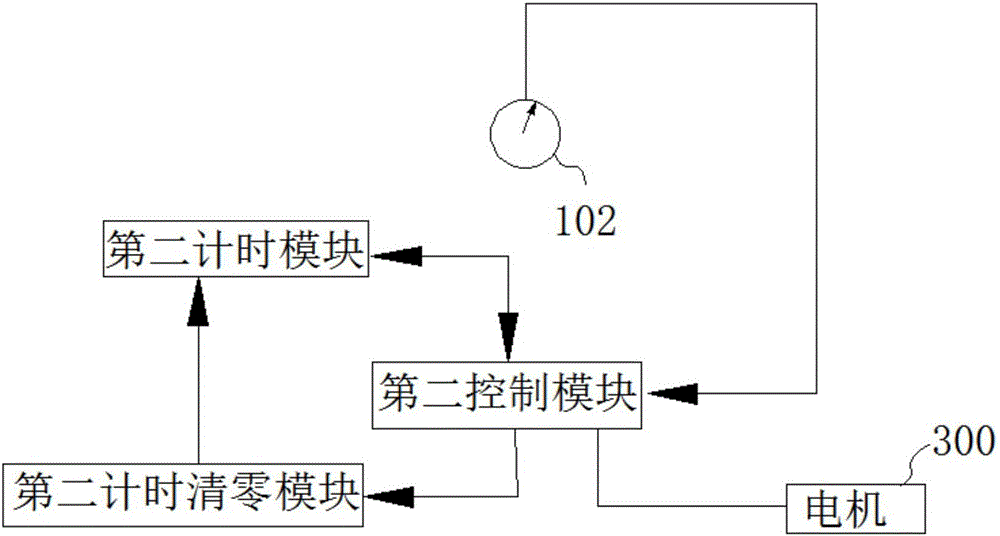

[0026] refer to figure 1 and figure 2 , a water pump (200) control system, including a main control board provided with an intelligent anti-rust card module and a small flow automatic detection control module, the intelligent anti-rust card module includes the internal pressure detection of the pum...

Embodiment 2

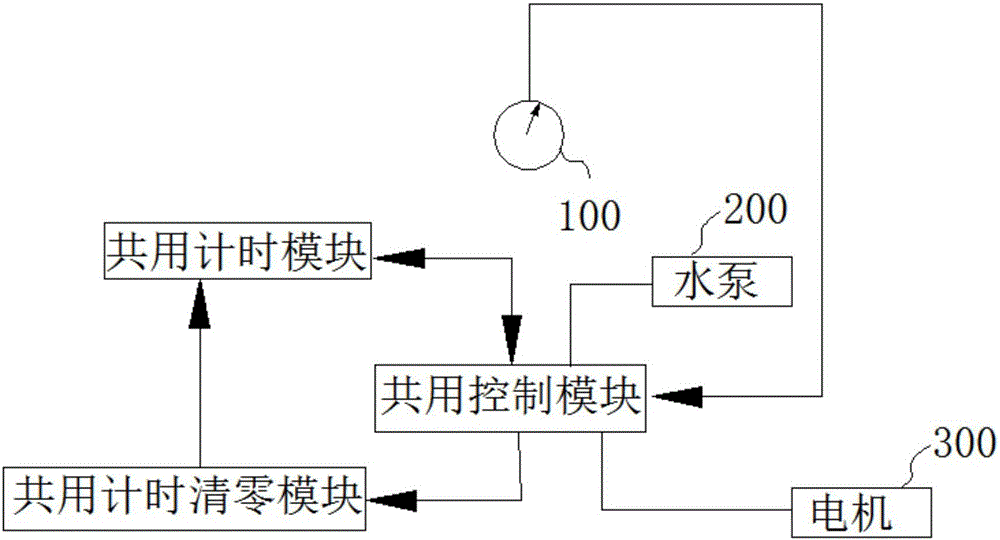

[0038] The parameters of this embodiment are: 1. The rated pressure of the pressure gauge (101) is the pressure value in the pump (200) of the rust card, and the value is input and written according to the model of the water pump (200); 2. The pre-set value of the rust card The setting time is 24 hours; 3. The marked pressure of the pressure gauge (102) refers to the normal pressure value without flow, which is written according to the model of the water pump (200); 4. The preset time for small flow control is 5 seconds. And the anti-rust card module of this embodiment and the small flow automatic detection control module share the pressure gauge (100), the timing module, the timing clearing module and the control module for operation. Its specific implementation is as follows:

[0039] refer to image 3 , the first pressure gauge (101) and the second pressure gauge (102) are the same pressure gauge, the first timing module and the second timing module are the same timing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com