Aviation engine blade profile measuring method

An aero-engine and measurement method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inability to obtain surface information, unsuitable for blade measurement, and high measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

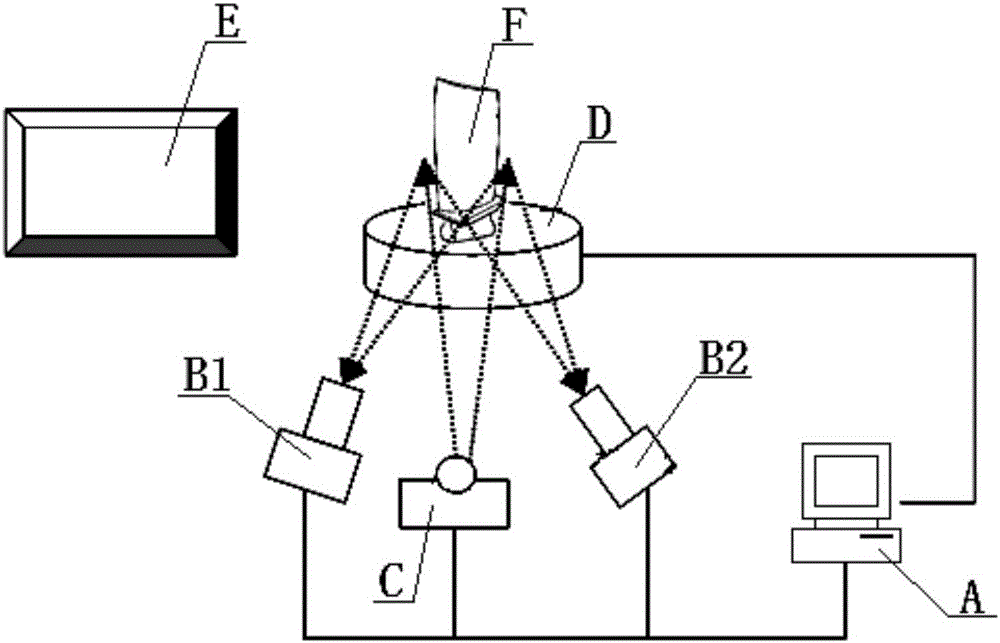

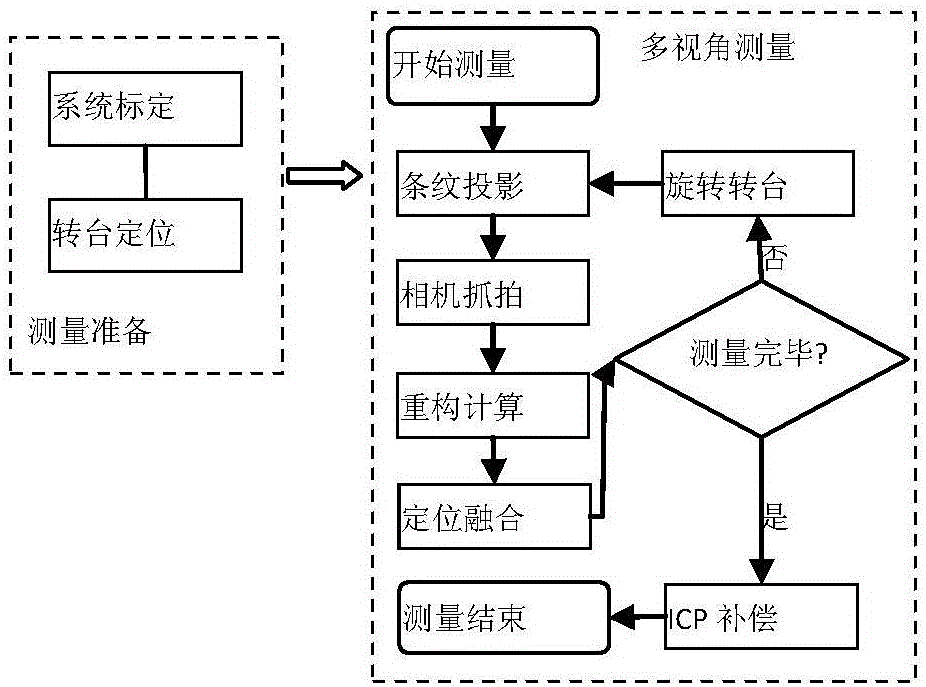

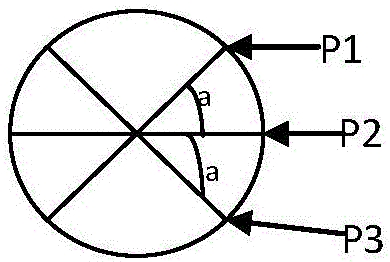

[0059] The present invention is the measurement method of aeroengine blade profile, at first, this measurement method is based on a measurement system (disclosed prior art), see figure 1 As shown, the measurement system includes computer A, binocular industrial cameras (B1, B2), projector C, turntable D and positioning plane E. Among them, the computer A is used to control the actions of the turntable D, the projector C and the binocular industrial cameras (B1, B2), and the corresponding data processing program is provided on the computer A, and the measurement data collected by scanning is processed through the processing program. deal with. The projector C is used to project the structured light onto the object to be measured on the turntable D—the blade F (ie, the blade of the aeroengine). The binocular industrial cameras (B1, B2) are used to capture the deformed fringe pattern generated by the projection of the projector C onto the measured object-blade F. The positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com