A method for measuring the profile of an aeroengine blade

A technology of aero-engine, measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

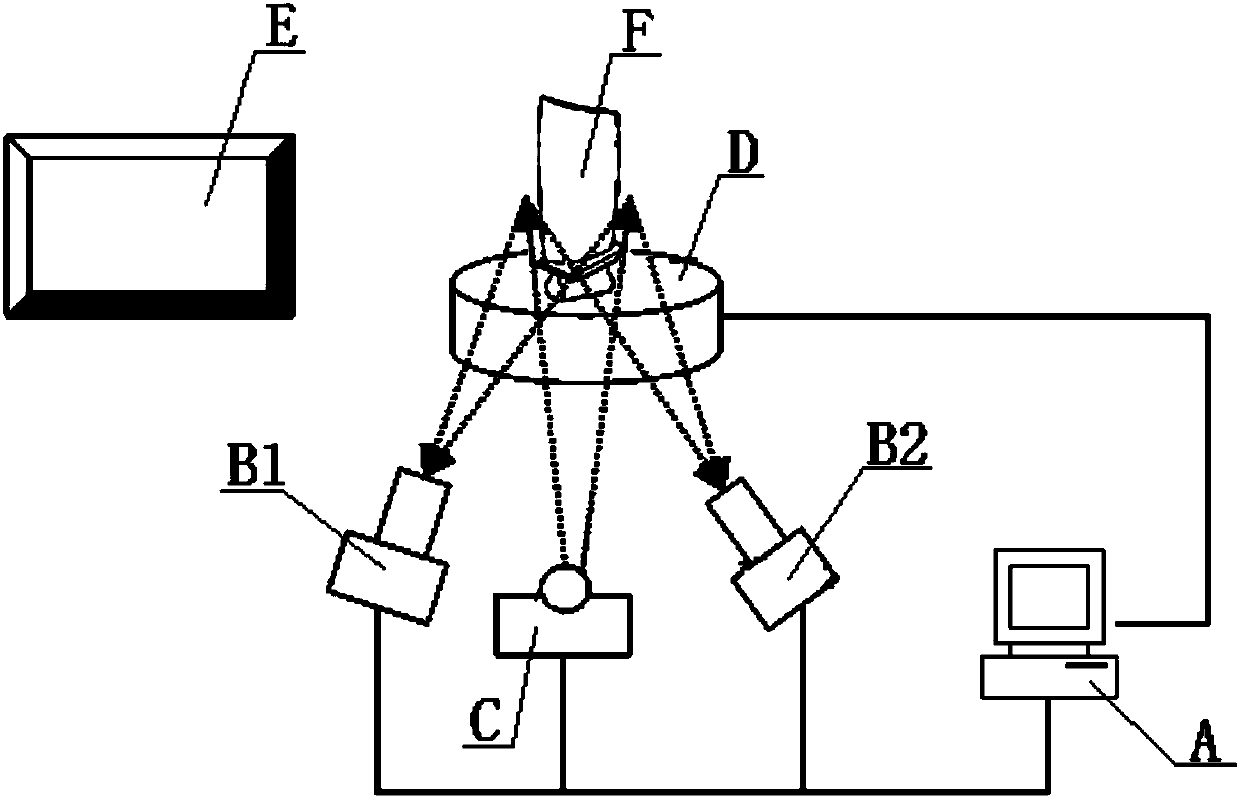

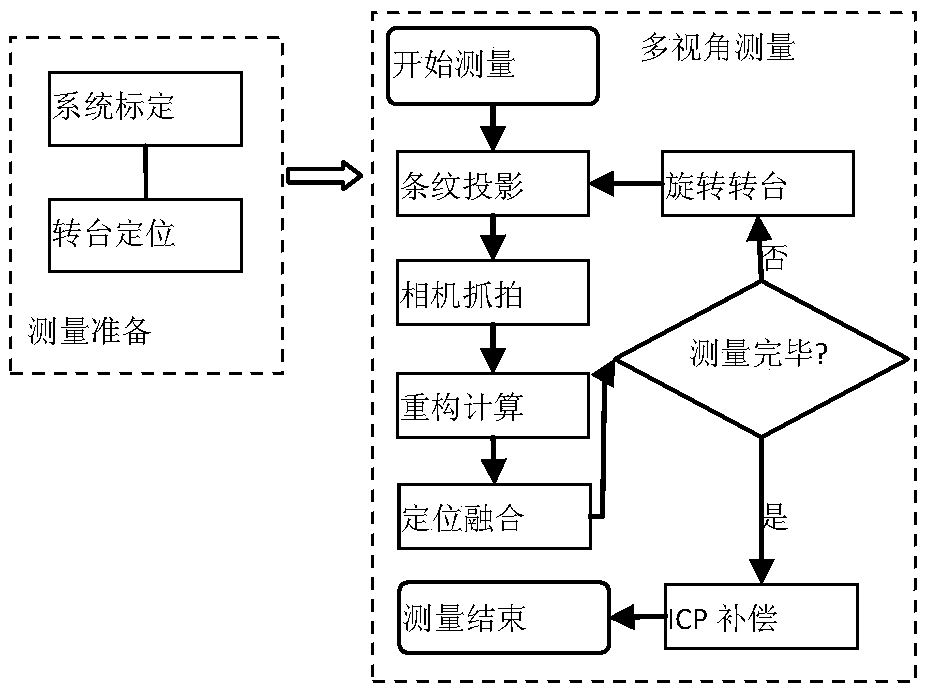

[0059] The present invention is a measurement method of aeroengine blade profile. First, the measurement method is based on a measurement system (disclosed prior art), see figure 1 As shown, the measurement system includes computer A, binocular industrial cameras (B1, B2), projector C, turntable D and positioning plane E. Among them, the computer A is used to control the action of the turntable D, the projector C and the binocular industrial camera (B1, B2), and the computer A is provided with a corresponding data processing program, and the measurement data collected by the scan is processed through the processing program. deal with. The projector C is used to project structured light onto the object to be measured on the turntable D-the blade F (that is, the blade of the aircraft engine). Binocular industrial cameras (B1, B2) are used to capture the deformed fringe pattern generated after the projector C is projected onto the measured object-the blade F. The positioning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com