Hand pulling type propulsion mechanism

A propulsion mechanism and hand-pull technology, which is applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problems of large drawer space, high cost, and inflexible operation, so as to improve the texture and grade and facilitate operation , fashion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

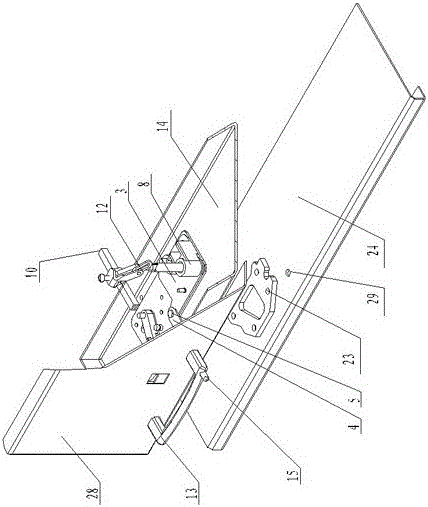

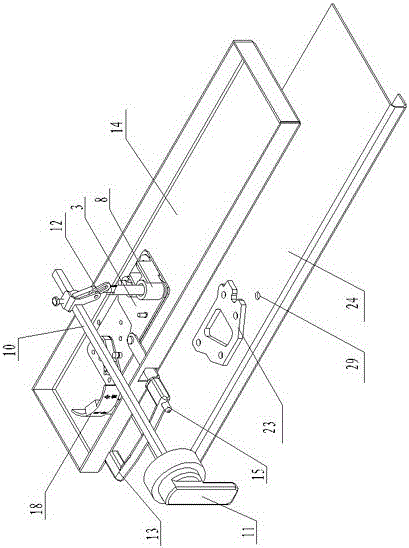

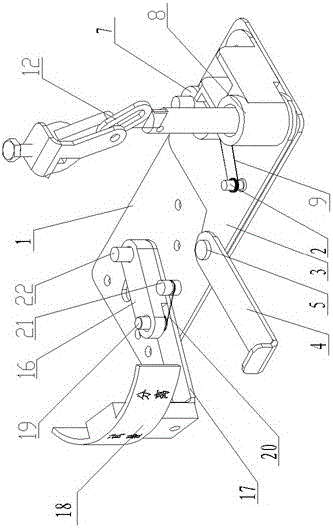

[0011] A hand-pull type propulsion mechanism, refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the interlocking bottom plate 14 is installed in the drawer 28, the interlocking bottom plate 14 is provided with the mechanism bottom plate 1, the interlocking plate 3 is installed above the mechanism bottom plate 1 through the rotating shaft 2, and the connecting plate 4 and the interlocking plate 3 pass through the fixed pin 5 Then, the lower end of the fixed pin 5 extends into the fixed pin hole 26 on the bottom plate of the mechanism for limiting, the torsion spring fixed block 7 is fixed above the interlocking plate 3 through the interlocking positioning pin 6, and the lower end of the interlocking positioning pin 6 extends into The interlocking pin hole 27 on the mechanism bottom plate 1 is limited, the positioning sleeve 8 is installed on the mechanism bottom plate 1 through bolts, and the two arms of the interlocking plate set on the rotating shaft 2 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com