Tray bearing assembly for machine cabinet, and screen cabinet and prefabricated cabin equipped with same

A technology for pallets and cabinets, which is applied in the field of pallet-carrying components for cabinets, which can solve the problems of multiple rear-end wiring, reduce labor intensity, meet operating requirements, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

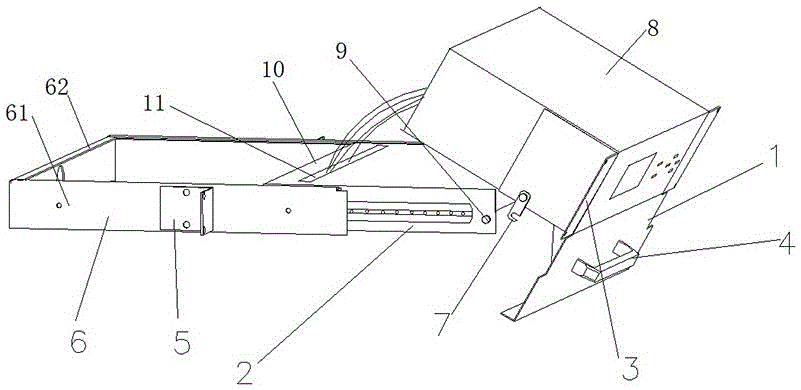

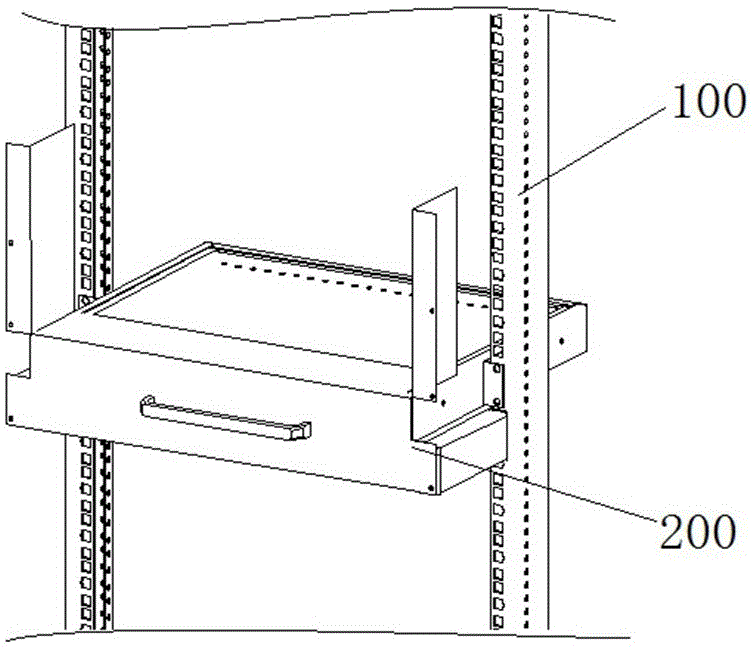

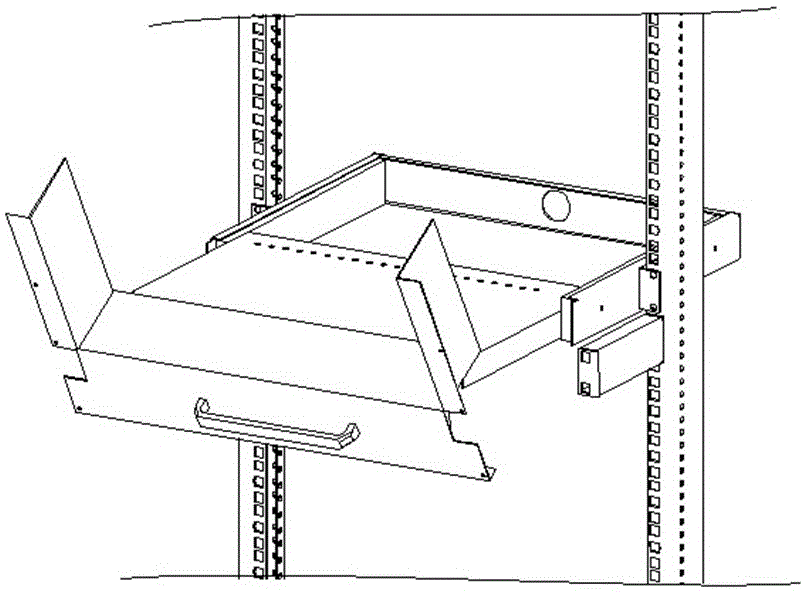

[0024] Such as figure 1 As shown, an embodiment of a tray carrying assembly for a cabinet, the tray carrying assembly for a cabinet in this embodiment includes a fixed frame 6 fixedly mounted on the cabinet body and a frame mounted on the fixed frame 6 guided and moved along the front and rear directions. Moving the guide rail 2, the fixed frame 6 includes rails 61 on both sides extending in parallel along the front-to-back direction and spaced apart along the left-right direction and the middle connecting plate 62 connected to the rear ends of the rails on both sides at both ends, specifically on both sides of the fixed frame 6 The outer side of the track is provided with fixed ears to connect with the cabinet body. The front end of the cabinet body is an open end. The fixed frame 6 is a door-shaped structure with the opening facing forward. Front and rear direction guiding movement is assembled on the cabinet body.

[0025] The front end of the moving guide rail 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com