Universal rotary type oil product filter cleaner provided with differential pressure alarm and replaceable filter element

A filter and alarm technology, applied in the mechanical field, can solve the problem of non-replaceable filter elements, and achieve the effect of increasing the area, improving the oil filtering efficiency, and increasing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

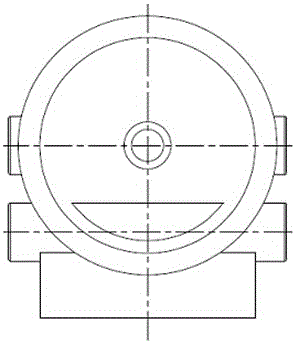

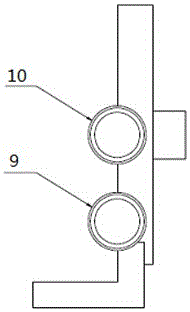

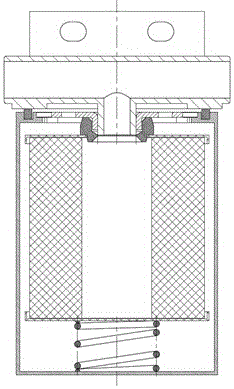

[0038] The oil filter of the present invention is installed in cooperation with the filter seat of the standard filter. figure 1 , figure 2 , image 3 It is a schematic diagram of the filter seat and the assembly of the filter seat and the filter. The filter seat includes an oil inlet channel 9 and an oil outlet channel 10. The oil outlet channel 10 is set at the center of the filter seat and is connected to the center of the filter mouth. The through hole is connected with the butt threaded through hole 15; the oil inlet channel 9 is arranged at the edge of the filter seat and communicated with several oil inlet through holes at the mouth of the filter.

[0039]In order to realize the reuse of the shell, the present invention designs a threaded connecting plate 2, which is detachably connected with the shell 1. In use, the filter element 4 is assembled with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com