Friction stir welding tool posture and position calibration device and calibration method

A friction stir welding and calibrating device technology, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as inability to achieve surface welding of complex workpieces, difficulty in ensuring consistency of weld strength, and complex shapes of areas to be welded. Achieve the effects of simple structure, improved welding quality and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

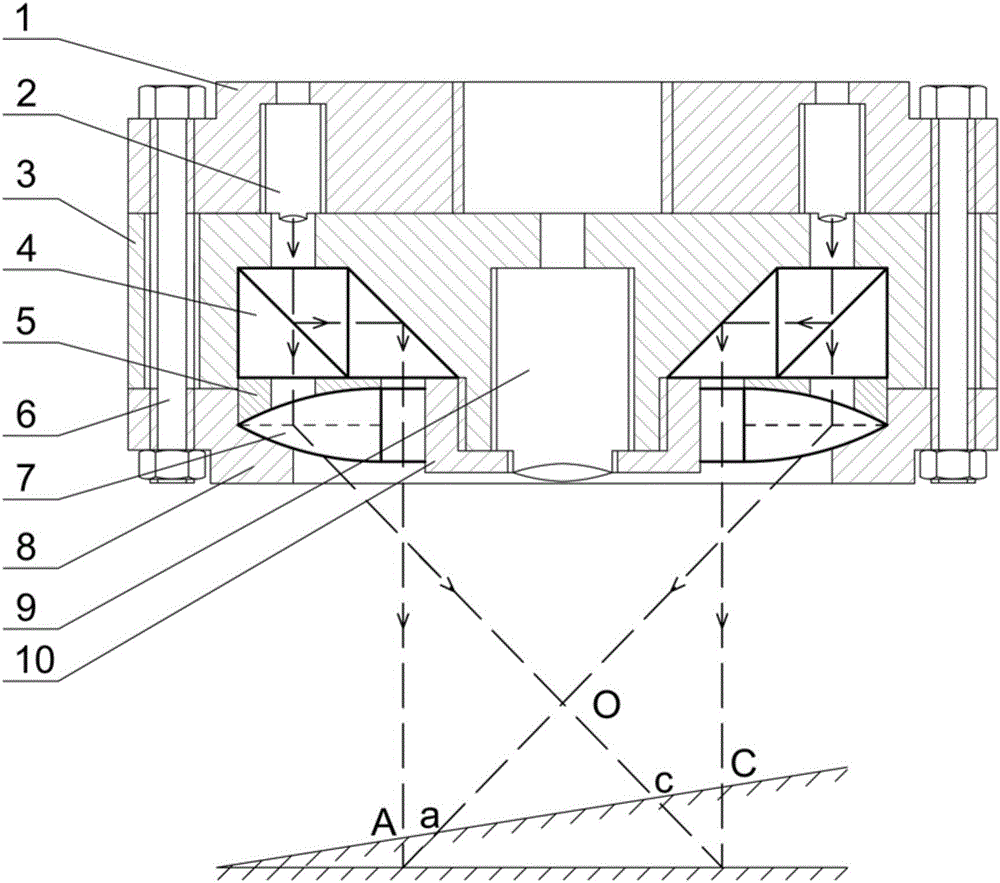

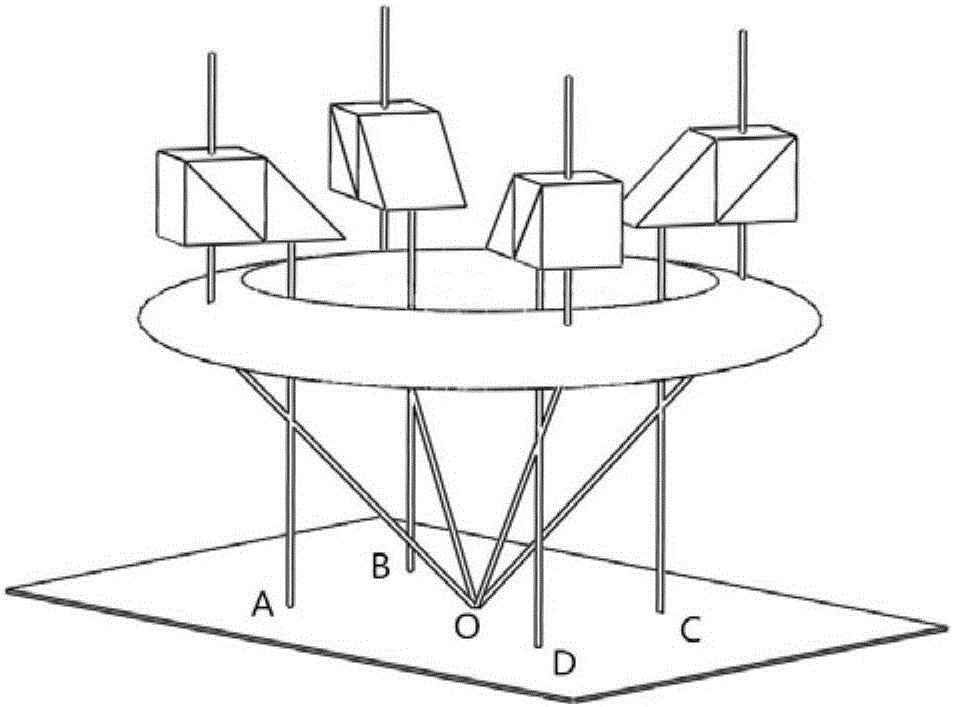

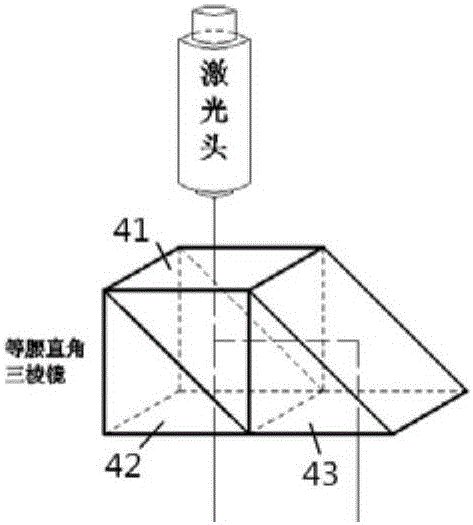

[0023] Such as Figure 1 to Figure 3 As shown, a friction stir welding tool posture and position calibration device of the present invention includes a camera 9, four prism bodies 4 and a convex lens 7, the camera 9 is located at the center of the main body bracket 3, and the camera 9 is fixed on the camera through a camera fixing plate 10 On the main body bracket 3, the camera 9 is connected with the display of the real-time display screen, the center of the convex lens 7 is provided with a through hole, the convex lens 7 is sleeved on the camera fixed plate 10, there is a gap between the inner wall of the convex lens 7 and the camera fixed plate 10, the convex lens 7 is connected with the main body support 3 through the lens fixing plate 5, and the convex lens 7 is installed on the main body support 3 through the base 8. The base 8 is provided with a stepped through hole, and the through hole is provided with a step with a circular arc shape in section, and the circular arc o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com