Automatic grinding device for outer profile of cast iron pan

A technology of external profile and cast iron pan, which is applied in the direction of grinding drive device, grinding frame, grinding bed, etc., can solve the problems of inconvenient operation, low efficiency, and inability to automatically control etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

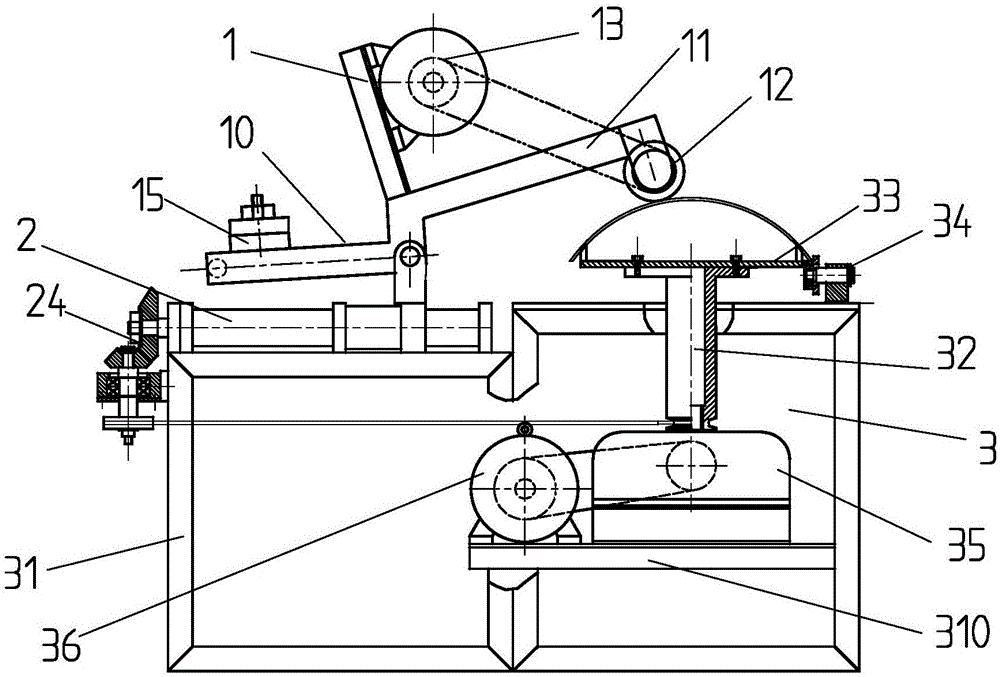

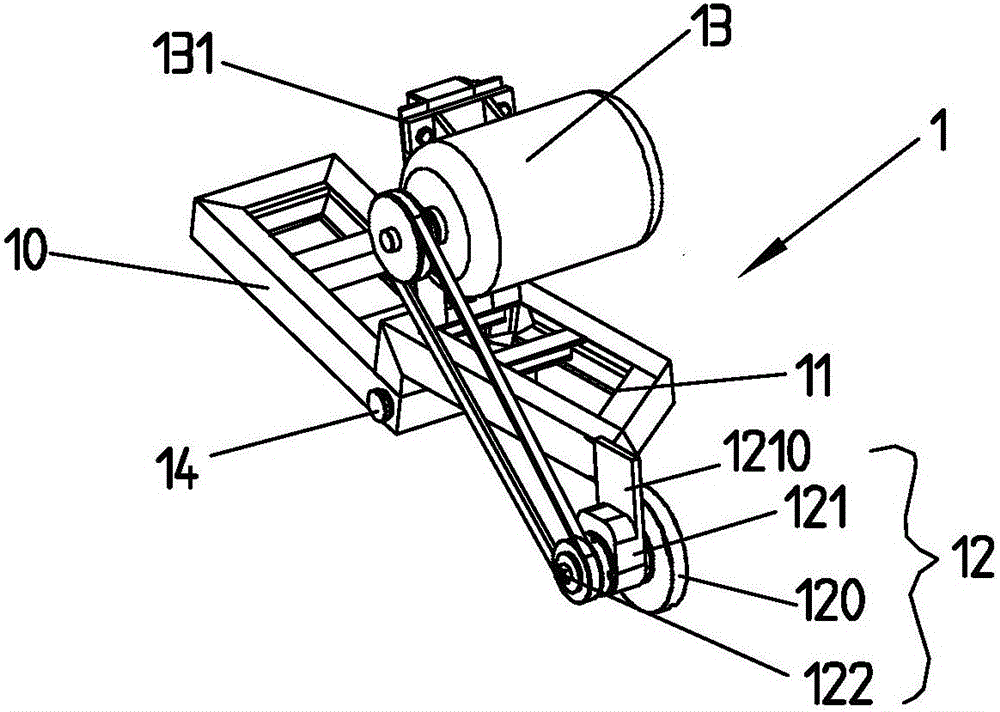

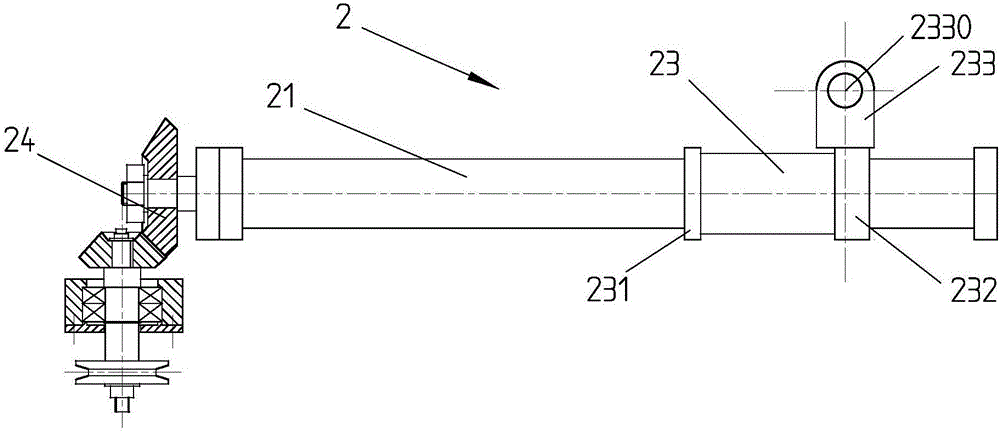

[0026] as attached figure 1 - attached Figure 6 The shown automatic grinding device for the outer surface of cast iron pots includes a support platform assembly 3, a moving mechanism 2 arranged on the support platform assembly 3, and a floating grinder rotatably arranged on the moving mechanism 2. head 1.

[0027] See Figure 5 and Figure 6 , the support platform assembly 3 includes a frame 31, a rotating disk 32 is rotatably installed on the frame 31, a pan tray 33 is arranged on the rotating disk 32, and the rotating disk 32 and the pan tray 33 are formed by the first The motor 36 is driven, and a reduction gear 35 is arranged between the rotating disc 32 and the first motor 36. The reduction gear 35 is a worm gear reducer, and the reduction gear 35 and the first motor 36 are fixed on the inner bracket 310. The inner frame 310 is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com