Machinery punching assembly

A technology for mechanical punching and assembly, applied in metal processing and other directions, can solve the problems of low safety, unsuitable for a large number of binding occasions, and low practicability, and achieve the effect of improving work efficiency, improving quality, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

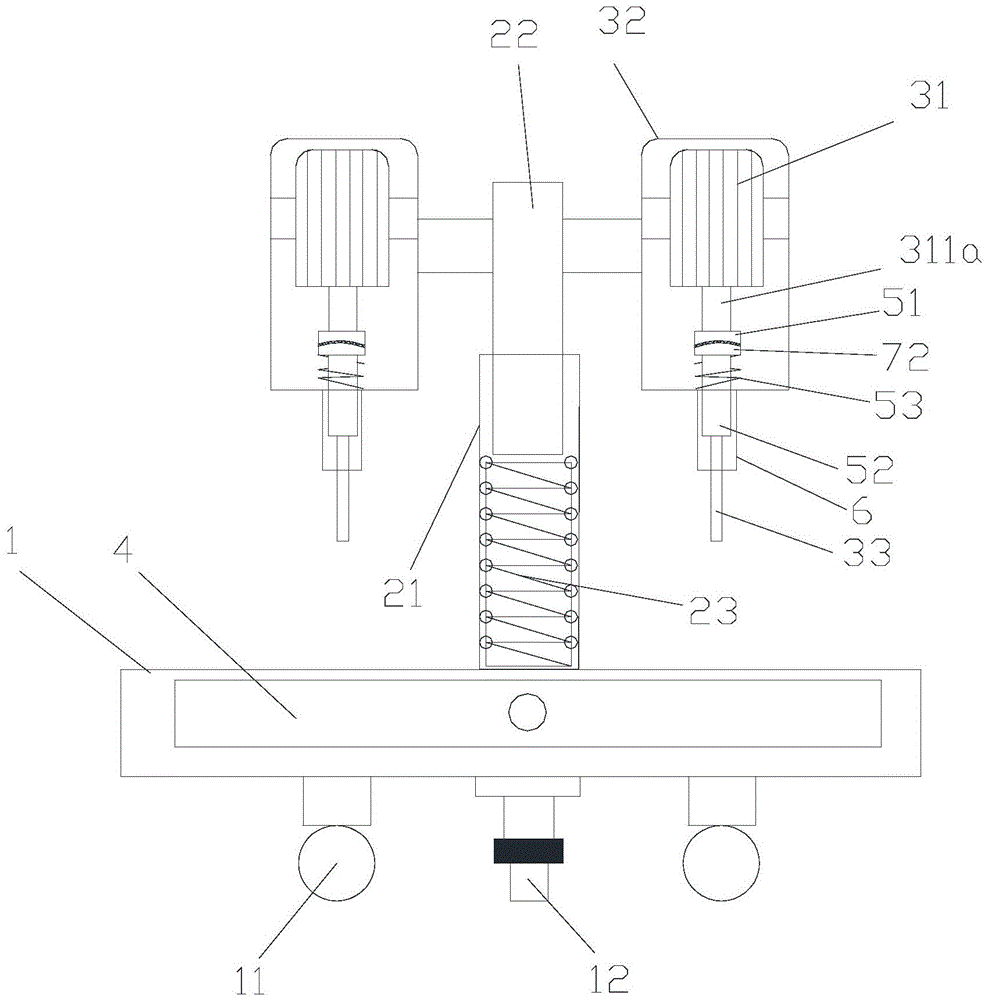

[0012] like figure 1 Shown: In this preferred embodiment, the mechanical punching assembly includes a machine base 1, a lifting mechanism and a punching mechanism, and the lifting mechanism includes a hollow outer rod 21 vertically arranged on the machine base 1, a coaxial The inner rod 22 sleeved in the outer rod 21 and the elastic return member 23 arranged in the outer rod 21 and abutting against the bottom of the inner rod 22; the roller 11 is provided under the base 1; the punching mechanism includes a motor 31. Machine box 32 and drill 33 for punching, the motor 31 is fixed in the machine box 32, the machine box 32 is fixedly connected with the inner rod 22, the crankshaft of the motor 31 faces downward and the crankshaft Pass through machine box 32 and drill bit 33 transmission connection; Described machine shaft comprises upper shaft 311a and the lower shaft 311b that is connected with described upper shaft 311a by slipping mechanism, when the transmission between descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com