Air deflating and inflating packaging machine

A technology of inflatable packaging and casing, applied in packaging, pressurized/gasified packaging, transportation packaging, etc., can solve the problems of air nozzle installation shaking, shortening of torsion spring life, air nozzle damage, etc., to reduce air leakage, Increased stability and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

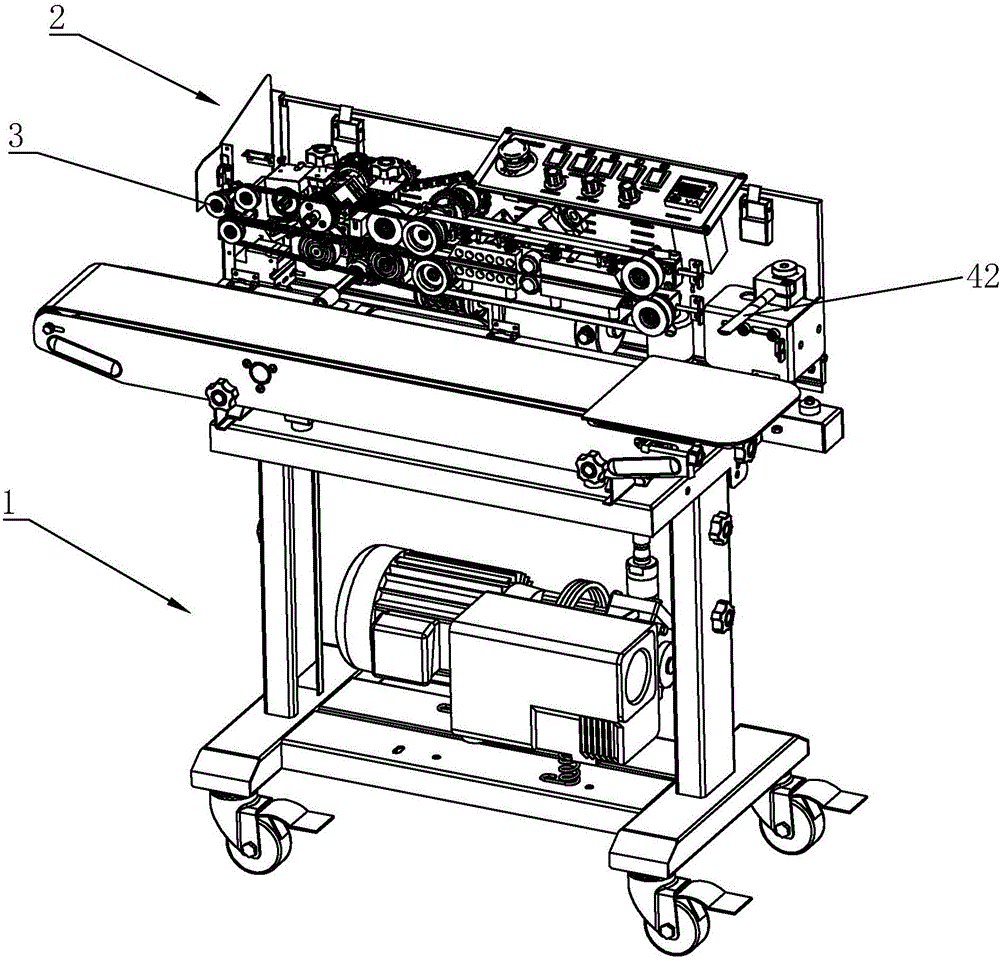

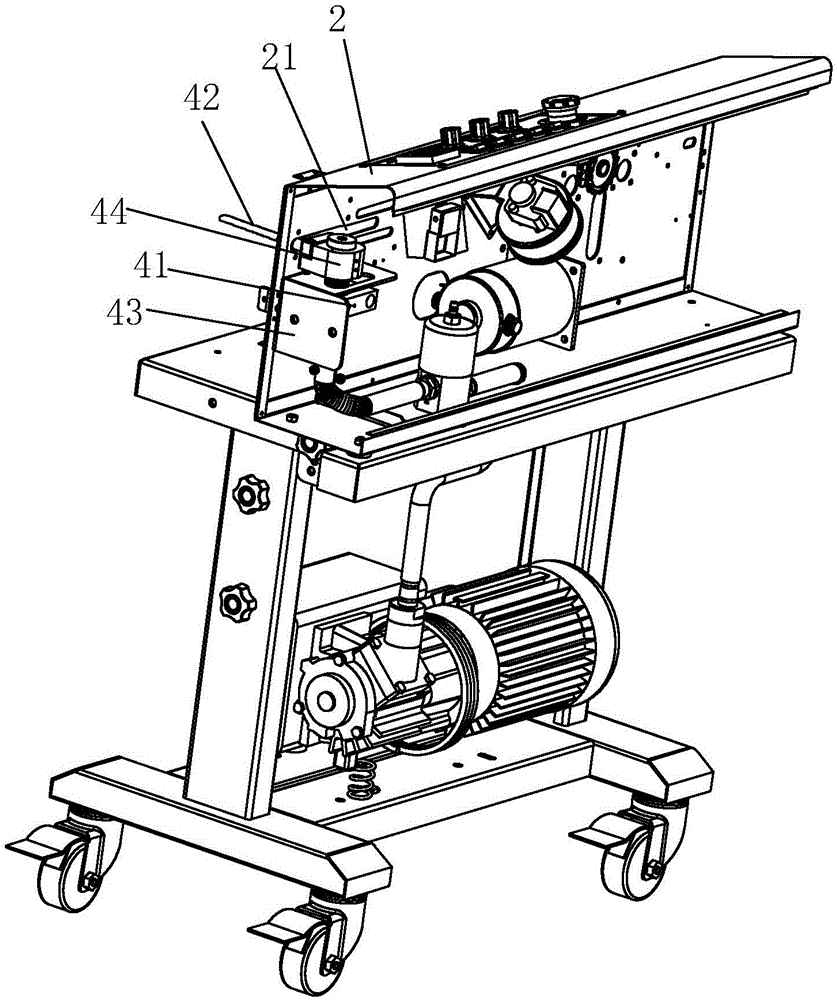

[0039] Embodiment 1: a kind of pumping and filling packaging machine, such as figure 1 with figure 2As shown, it includes a frame 1 and a casing 2. The casing 2 is provided with a heat-sealing device 3 and a composite device for vacuuming and inflating operations. The composite device is located on the inlet side of the heat-sealing device 3. The composite device includes a base 41 and the gas nozzle 42, the base 41 is fixed to the casing 2 through the mounting plate 43, and the casing 2 is provided with a groove 21 through which the gas nozzle 42 passes, wherein the gas nozzle 42 is clamped on the mounting seat 44, and the mounting seat 44 and the base 41 are rotatably connected to realize the rotatability of the air nozzle 42, and a resetting torsion spring for rotating and resetting is provided between the mounting seat 44 and the base 41.

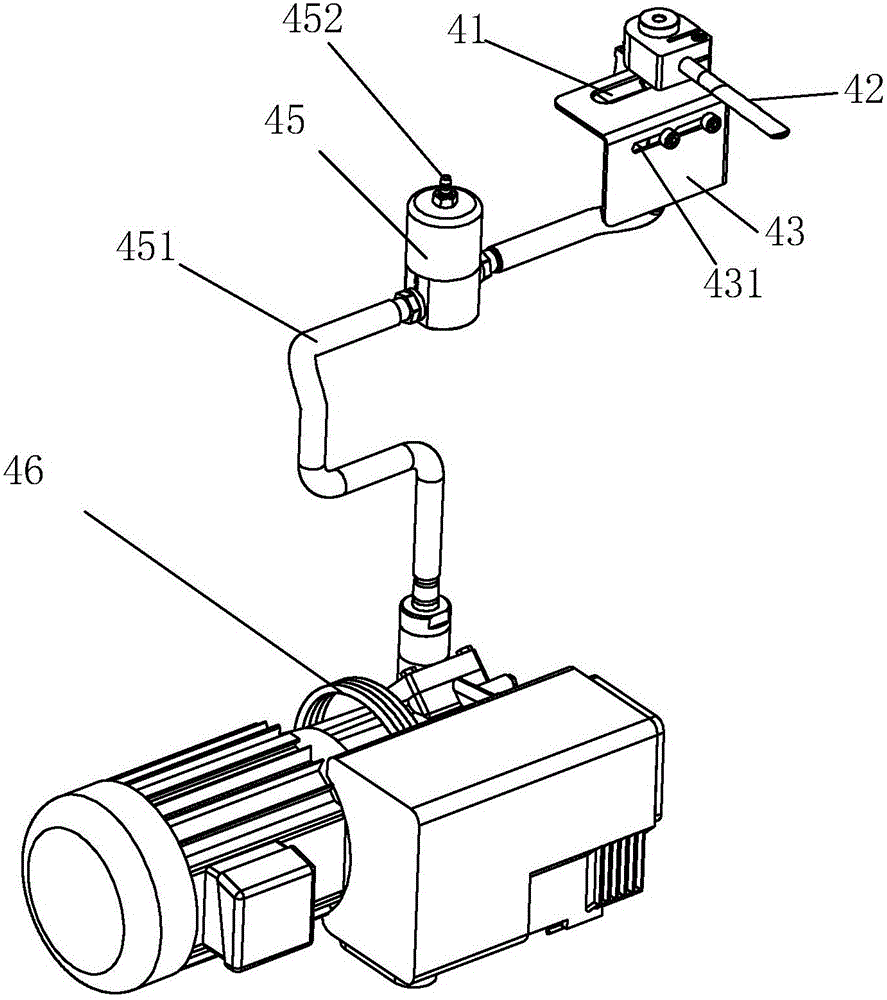

[0040] Such as image 3 As shown, the base 41 is connected with a pipeline communicating with the gas nozzle 42, the pipeline is co...

Embodiment 2

[0045] Embodiment 2: a kind of pumping and inflating packaging machine, such as Image 6 with Figure 7 As shown, its difference from Embodiment 1 is that the magnetic block 51 is an electromagnet, and the inner wall of the bar groove 21 is provided with a magnetic sensor a61 and a magnetic sensor b62; when needed, the electromagnet will generate magnetic force to eliminate The inertia of the rotation makes it stop quickly. When it is not needed, the electromagnet will not generate magnetic force after turning on the power supply and disconnecting the power supply. The subsequent rotation operation does not need to overcome the magnetic force, and this control is realized through the magnetic sensor a61 and the magnetic sensor b62 .

[0046] Such as Figure 8 As shown, the frame 1 is provided with a support platform for supporting the product, the support platform includes a frame body 71, the frame body 71 is provided with a roller body 73 and a support belt 72, and the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com