Combination method of catalytic diesel hydroconversion and catalytic gasoline selective hydrogenation

A technology for catalyzing gasoline and hydroconversion, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., to achieve the effect of reducing hydrogen consumption, reducing carbon deposition and prolonging operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

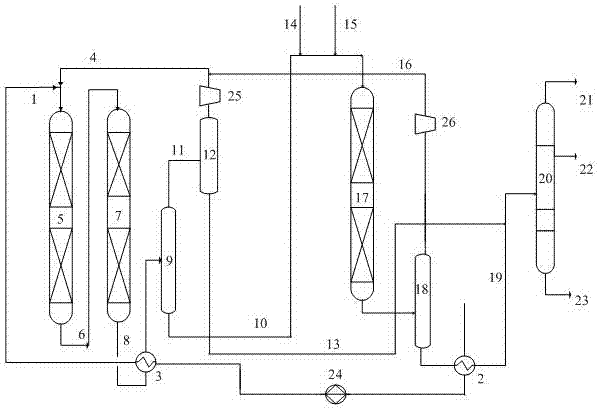

[0040] Embodiment 1-3 adopts flow process of the present invention as figure 1 .

[0041] In the present invention, the pretreatment catalyst used in the partial refining section of catalytic diesel hydroconversion is FF-36 hydrogenation pretreatment catalyst widely used in this field. The non-noble metal catalyst generally exists in an oxidized state before use, and needs to be presulfurized so that the non-noble metal oxide can be converted into a sulfide to be reactive. Therefore, non-noble metal catalysts should remain in a sulfurized state during use. The bulk phase method catalyst that adopts in embodiment 1-3 is the FTX catalyst of industrial application, and cracking agent is the cracking catalyst that adopts conventional method to prepare, and in embodiment 1-3, carry out gradient mixing filling to hydrocracking reactor, in the reactor A total of 3 mixed catalyst beds with the same packing volume are included. According to the order of contact with the reaction mate...

Embodiment 4

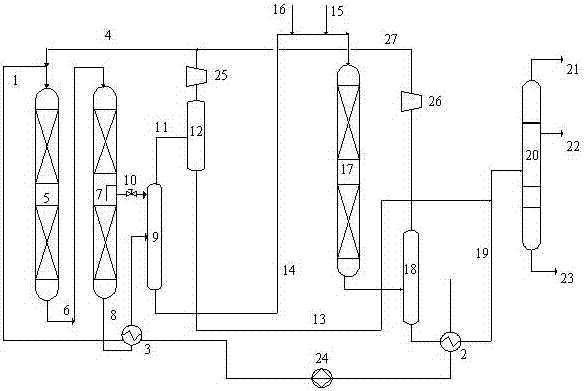

[0043] use figure 2 process shown. Feedstock oil, and catalyst used are the same as embodiment 3. Wherein a gas extraction pipeline is set between the second and third cracking catalyst beds, and the others are the same as in Embodiment 3. The amount of gas phase material drawn from the gas phase extraction pipeline is 30% of the amount of circulating hydrogen.

[0044] The process conditions and results of the examples are listed in Table 3 and Table 4 respectively.

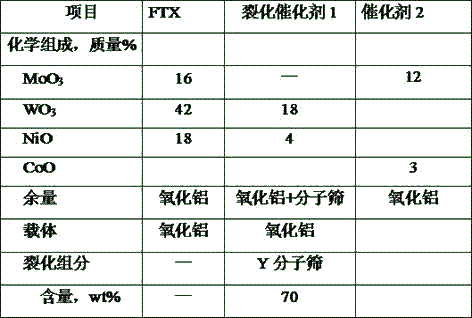

[0045] Table 1 Composition and main properties of the cracking catalyst of the example.

[0046]

[0047] Table 2 Raw oil properties.

[0048]

[0049] Table 3 Operating conditions used in Examples 1-4.

[0050]

[0051] Table 4 Evaluation results of Examples 1-4.

[0052] Example 1 Example 2 Example 3 Example 4 Catalytic Diesel Hydroconversion Section Product distribution, wt% Naphtha fraction fraction ( 39 38 52 54 Diesel Distillate (>21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com