Method for synthesizing melonal

A technology of melon and formaldehyde, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of high COD wastewater, high acid-base unit consumption, complex process flow, etc. High rate, simplified operation, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

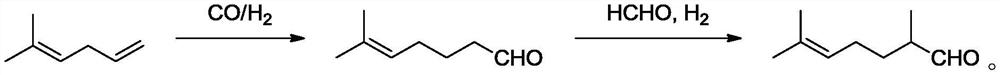

[0041] Rhodium-catalyzed hydroformylation of 5-methyl-1,4-hexadiene to 6-methyl-5-heptenal.

[0042] In the glove box, weigh [Rh(acac)(CO) 2 ] (89mg, 0.25mmol), 1,2-bis(diphenylphosphine)ethane (113mg, 0.28mmol) and tricyclohexylphosphine (154mg, 0.55mmol) were placed in a single-necked flask with a magnetic stir bar , Then add the solvent toluene (30mL), after the single-necked flask is sealed, after stirring and coordinating at room temperature for 20 minutes, take it out from the glove box. Under the protection of a nitrogen balloon, the catalyst solution was pumped into a 250mL autoclave with an advection pump. The autoclave had been replaced with nitrogen and synthesis gas three times in advance. The autoclave was filled with synthesis gas and the pressure was normal pressure. After the catalyst solution is fed, start stirring, then put the raw material 5-methyl-1,4-hexadiene (48.1g, 0.5mol) and the solvent toluene (70mL) into the autoclave, and finally fill the reaction...

Embodiment 2

[0044] Rhodium-catalyzed hydroformylation of 5-methyl-1,4-hexadiene to 6-methyl-5-heptenal.

[0045] In the glove box, weigh [Rh(acac)(CO) 2 ] (21mg, 0.06mmol), 1,2-bis(diphenylphosphine)ethane (72mg, 0.18mmol) and tricyclohexylphosphine (50mg, 0.18mmol) were placed in a single-necked flask with a magnetic stir bar , Then add the solvent toluene (30mL), after the single-necked flask is sealed, after stirring and coordinating at room temperature for 20 minutes, take it out from the glove box. Under the protection of a nitrogen balloon, the catalyst solution was pumped into a 250mL autoclave with an advection pump. The autoclave had been replaced with nitrogen and synthesis gas three times in advance. The autoclave was filled with synthesis gas and the pressure was normal pressure. After the catalyst solution is fed, start stirring, then put the raw material 5-methyl-1,4-hexadiene (57.7g, 0.6mol) and the solvent toluene (70mL) into the autoclave, and finally fill the reaction k...

Embodiment 3

[0047] Rhodium-catalyzed hydroformylation of 5-methyl-1,4-hexadiene to 6-methyl-5-heptenal.

[0048] In the glove box, weigh [Rh(acac)(CO) 2 ] (107mg, 0.3mmol), 1,2-bis(diphenylphosphine)ethane (131mg, 0.33mmol) and tricyclohexylphosphine (93mg, 0.33mmol) were placed in a single-necked flask with a magnetic stir bar , Then add the solvent toluene (30mL), after the single-necked flask is sealed, after stirring and coordinating at room temperature for 20 minutes, take it out from the glove box. Under the protection of a nitrogen balloon, the catalyst solution was pumped into a 250mL autoclave with an advection pump. The autoclave had been replaced with nitrogen and synthesis gas three times in advance. The autoclave was filled with synthesis gas and the pressure was normal pressure. After the catalyst solution is fed, start stirring, then put the raw material 5-methyl-1,4-hexadiene (28.9g, 0.3mol) and the solvent toluene (50mL) into the autoclave, and finally fill the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com