Quick spheroidal annealing thermal treatment process for Cr12 extruded seamless steel tube

A technology for annealing heat treatment and seamless steel pipes, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effect of shortening the time of spheroidizing annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

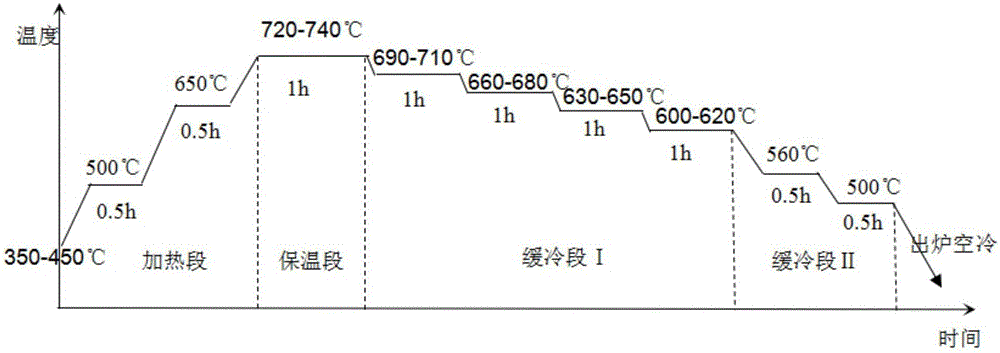

[0021] Continuous heat treatment furnace is adopted, and the spheroidizing annealing process curve is shown in the attachment figure 1 . Cr12 extruded billet size: outer diameter Ф300mm, inner diameter Ф45mm, length 520mm, extruded seamless pipe size is outer diameter Ф196mm, thickness 12mm.

[0022] After extrusion, the temperature of the steel pipe is above 1000°C, air-cooled to 350-450°C, and put into the furnace for spheroidizing annealing. The temperature in the furnace section is 600°C, which plays the role of slow heating. ℃, keep warm for 1~2h, the slow cooling section I is longer, the temperature is controlled in 4 sections, the temperature is 690~710℃, 660~680℃, 630~650℃, 600~620℃, and the temperature drop is guaranteed to be ≤30℃ / h, the slow cooling section II is divided into two sections of temperature control, one section with a temperature of 570°C, and the other section with a temperature of 500°C, and the furnace is air-cooled. The hardness is 230-260HB, whi...

Embodiment 2

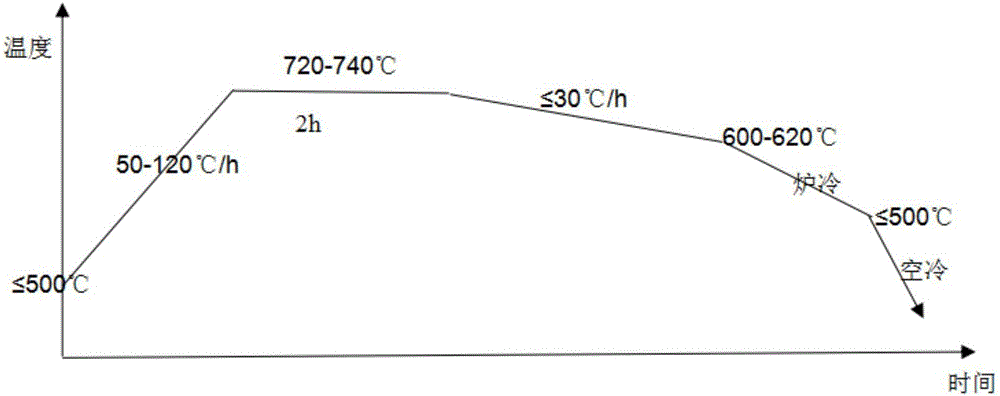

[0024] Periodic heat treatment furnace is adopted, and the spheroidizing annealing process curve is shown in the appendix figure 2 . Due to the fast pace of extrusion production and the slow pace of continuous heat treatment furnace, the above-mentioned Cr12 extruded seamless pipes are air-cooled to 400°C and slowly cooled in a slow cooling pit. During heat treatment, the furnace temperature is 400°C (it can also be put into the furnace at room temperature, the temperature of the front furnace is 500°C, and the furnace temperature is about 400°C after the furnace is discharged and loaded), and the heating rate is controlled at 100°C / h. At 740-720°C, keep warm 1~2h, cooling according to the above-mentioned two-stage cooling rate, cooling down to 600~620°C at a cooling rate of ≤30°C / h, and then adopting furnace cooling, and air cooling when the furnace temperature is not higher than 500°C. The hardness is 220-250HB. It can be seen that the hardness of periodic spheroidizing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com