Alpaca opener

An opener and alpaca wool technology, which is applied to fiber opening and cleaning machines, tooth-shaped tools, etc., can solve the problems of alpaca hair breaking, heavy holding of alpaca fibers, and large fiber damage, reducing the Damage, opening effect is good, the effect of reducing the speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

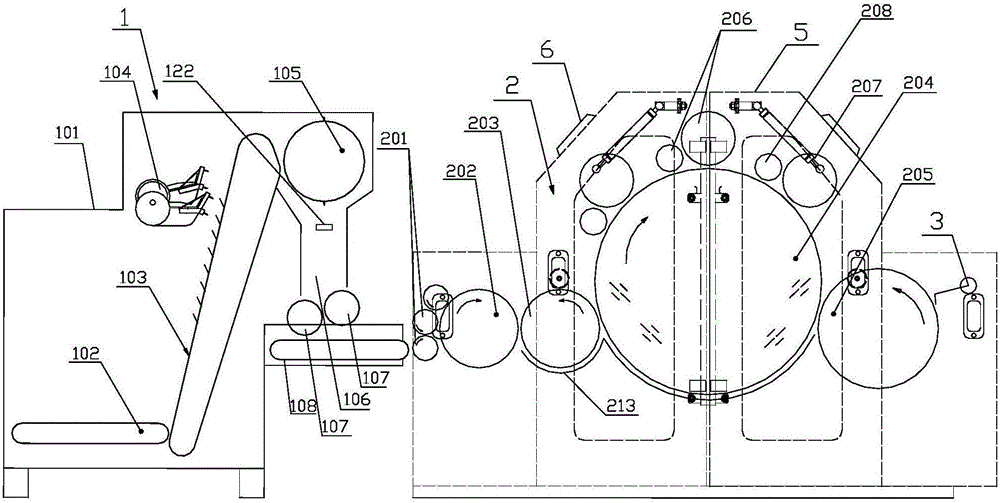

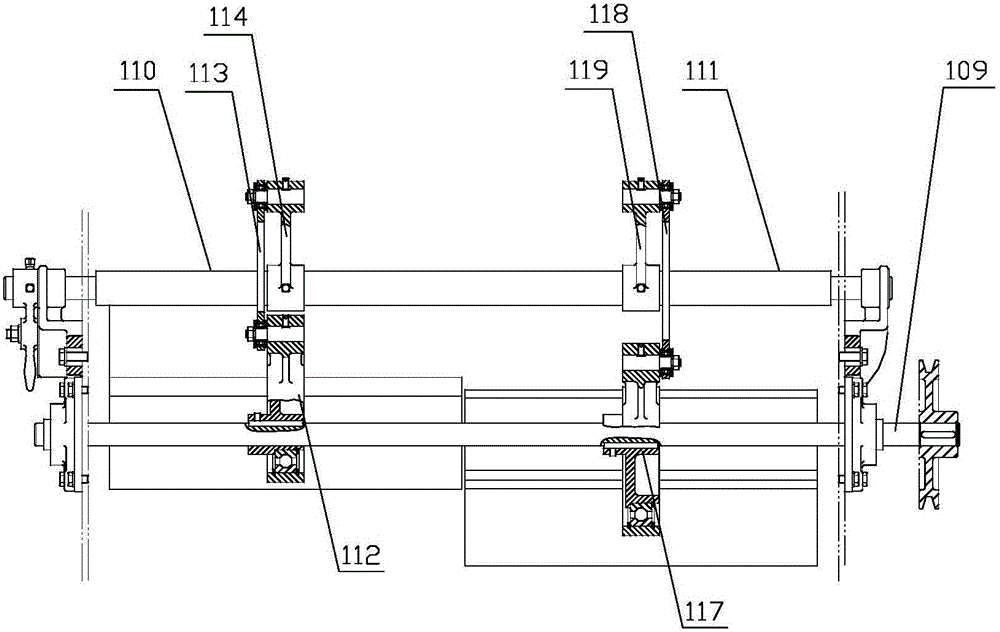

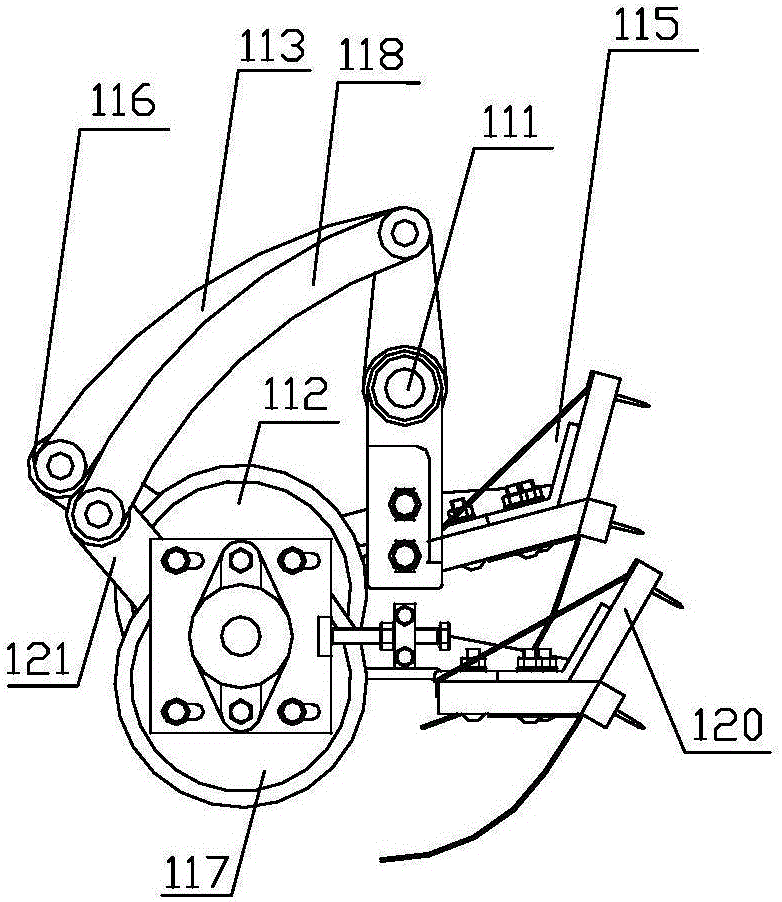

[0025] combine figure 1 As shown, the alpaca hair opening machine includes a feeding mechanism 1, an opening mechanism 2 and a stripping mechanism 3. Wherein, the feeding mechanism 1, the opening mechanism 2 and the stripping mechanism 3 are arranged sequentially from the back to the front.

[0026] The feeding mechanism 1 includes a feeding box 101, in which a bottom flat curtain 102, an oblique nail curtain 103, an even hair rake 104, a peeling roller 105, a volume box 106, a pressing roller 107 and a conveying flat curtain 108 are arranged in the feeding box 101 .

[0027] Wherein, the bottom flat curtain 102 is positioned at the rear side lower part of the feeding box 101, and the bottom of the oblique nail curtain 103 is positioned at the front side of the bottom flat curtain 102 and is inclined towards the front and upward. The even hai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com