A kind of plain shaded double-sided jacquard velvet and its weaving method

A double-sided jacquard and shadow technology, applied in the field of velvet fabrics, can solve the problems of lack of beauty, inability to meet customers' pursuit of high-end velvet fabrics, and inability to form jacquard patterns, and achieve the effect of good pile directionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

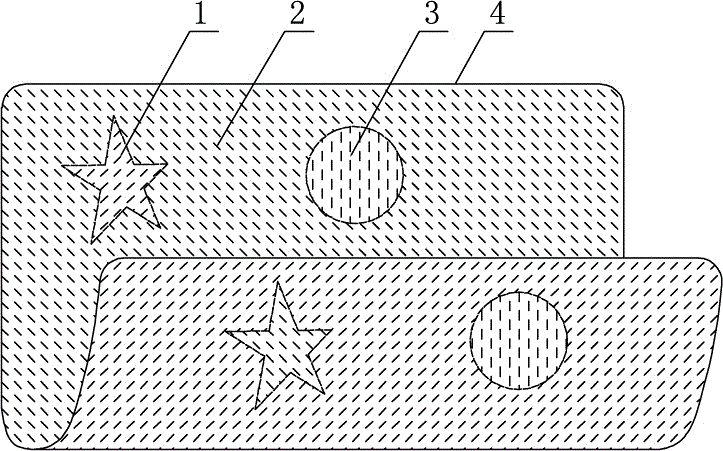

[0046] Such as figure 1 As shown, the plain shaded double-sided jacquard velvet of the present invention comprises a base cloth 4, on both sides of the base cloth are provided with suede made of pile, on the suede surface has a forward pile region 2, a backward slope Plain shaded pattern formed by pile zone 1 and standing pile zone 3.

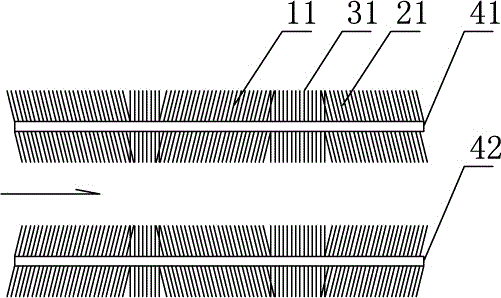

[0047] Such as figure 2 As shown, the piles are divided into forward-leaning piles 21, backward-leaning piles 11, and erect piles 31 according to the direction in which they stand. Pile Zone, Backward Pile Zone and Standing Pile Zone.

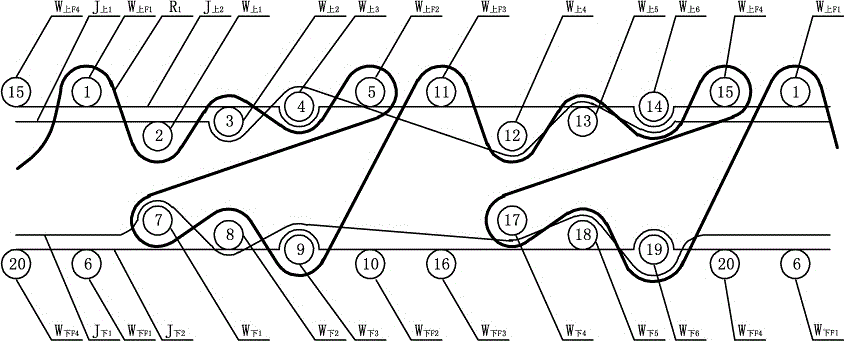

[0048] Such as image 3 — Figure 8 As shown, the base fabric is composed of tight warp yarns, loose warp yarns, and base fabric weft yarns. The tight warp yarns and loose warp yarns are woven together to make the base fabric weft yarns form a group of three in the warp direction and form a ↘ or ↗ shape with the base fabric plane. Or →-shaped arrangement, the pile warp yarns are consolidated on the three b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com