Construction method for CRTS III plate type ballastless track bed plate

A technology of slab-type ballastless track and construction method, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of difficult to guarantee accuracy, high flatness control requirements, and top elevation, etc., so as to ensure the top elevation and improve construction. Ergonomic, strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

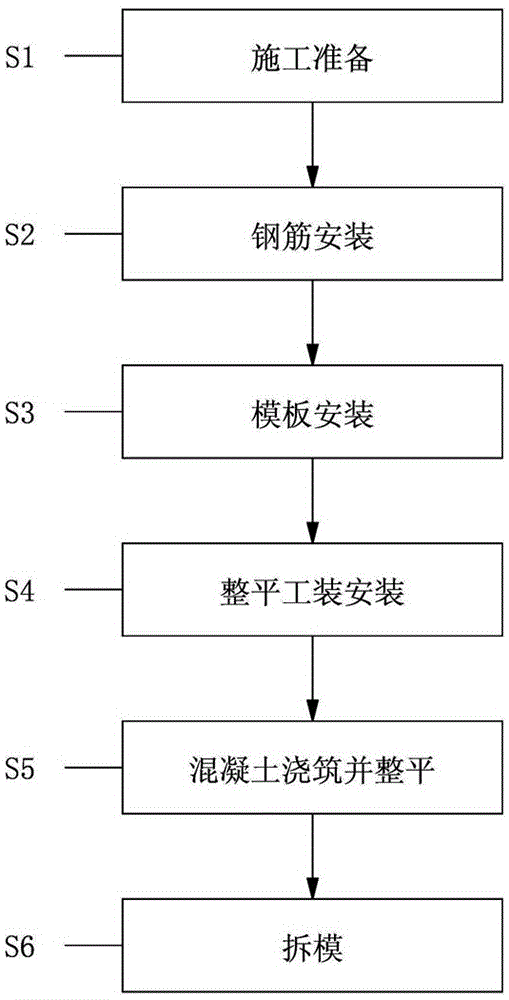

[0026] figure 1 The flow chart of an embodiment of a construction method for a CRTSⅢ slab ballastless track base plate of the present invention is shown, and the construction method includes the following steps:

[0027] S1: Construction preparation: complete the inspection and acceptance of the chiseling on the beam surface, organize materials and equipment to enter the site, measure the four corner points of the base plate and stake out, record the elevation of the stake out points, and use ink lines to pop up the corner points between the four corner points. Wire;

[0028] S2: Reinforcement installation: The reinforcement mesh is laid in two layers. First, the bottom layer of reinforcement mesh is laid according to the connection line of the corner points, and then the L-shaped connection reinforcement is installed in the connecting sleeve embedded in the beam surface. After completion, the top layer of reinforcement mesh is laid. It is supported and fixed by L-shaped conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com