Coal bed methane drainage and production control method and device

A control method and coalbed methane technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems affecting the service life of drainage equipment, frequent adjustment frequency, and fluctuations in bottomhole flow pressure, so as to avoid well Large fluctuations in bottom flow pressure and the effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

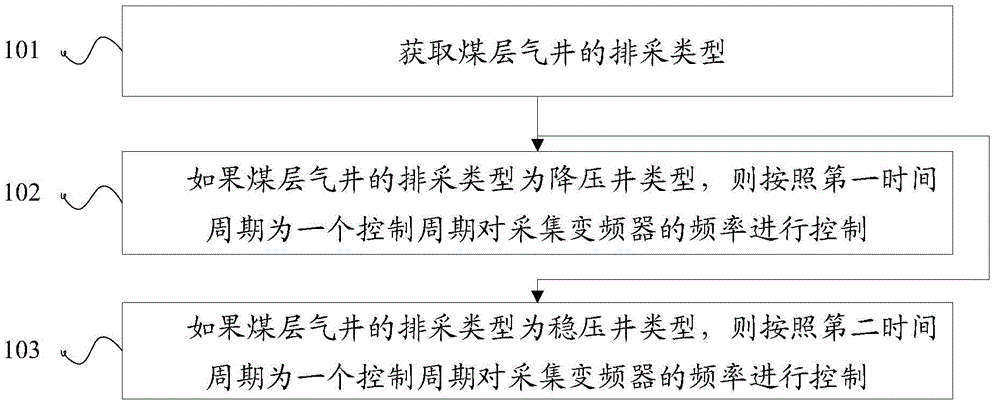

[0059] The embodiment of the present invention provides a control method for coalbed methane extraction, see figure 1 , the method flow includes:

[0060] 101: Obtain the drainage type of the coalbed methane well;

[0061] 102: If the drainage type of the coalbed methane well is a decompression well type, control the frequency of the acquisition frequency converter according to the first time period as a control period;

[0062] Among them, the frequency control methods of the acquisition frequency converter of the pressure-reduction well type include:

[0063] Acquiring the first bottomhole flowing pressure of the current control period detected by the pressure gauge, and comparing the first bottomhole flowing pressure of the current control period with the first ideal bottomhole flowing pressure of the current control period in the preset ideal bottomhole flowing pressure drop curve;

[0064] If the first bottomhole flowing pressure in the current control period is greater...

Embodiment 2

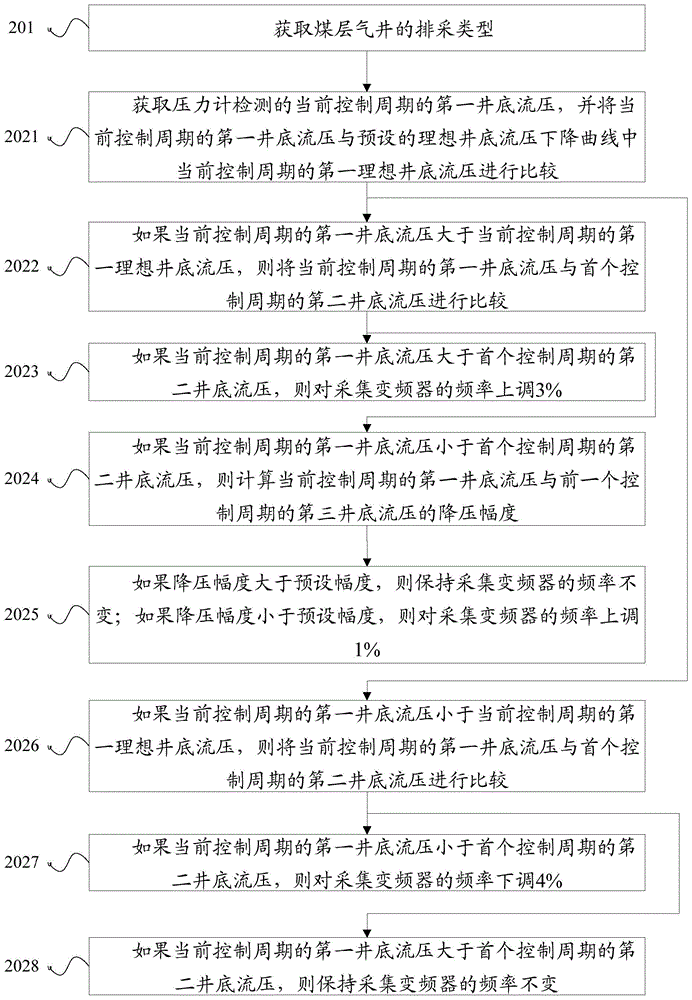

[0073] The embodiment of the present invention provides a control method for coalbed methane extraction, see figure 2 , the method flow includes:

[0074] 201: Obtain the drainage type of the coalbed methane well.

[0075] Among them, the drainage type may include two types, respectively: pressure-reducing well type and pressure-stabilizing well type. In the embodiment of the present invention, the decompression well type is taken as an example for illustration.

[0076] 202: If the drainage type of the coalbed methane well is a decompression well type, control the frequency of the acquisition frequency converter according to the first time period as a control period.

[0077] Wherein, the first time period may be two hours, that is, the frequency of the acquisition frequency converter is controlled at a frequency of once every two hours, and every two hours belongs to a control period, which is controlled 12 times a day.

[0078] Whenever a control cycle is entered, the s...

Embodiment 3

[0100] The embodiment of the present invention provides a control method for coalbed methane extraction, see Figure 4 , the method flow includes:

[0101] 401: Obtain the drainage type of the coalbed methane well.

[0102] Among them, the drainage type may include two types, respectively: pressure-reducing well type and pressure-stabilizing well type. In the embodiment of the present invention, the type of the stabilizing well is taken as an example for illustration.

[0103] 402: If the drainage type of the coalbed methane well is a stabilizing well type, control the frequency of the acquisition frequency converter according to the second time period as a control period; wherein, the first time period is different from the second time period;

[0104] Wherein, the second time period may be half an hour, that is, the frequency of the acquisition frequency converter is controlled according to the frequency of once every half hour, and every half hour belongs to a control per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com