System and method for regulating and controlling pH value of dephenolization device

A technology of dephenolization and pH value, which is applied in the direction of control/adjustment system, chemical instrument and method, control of various fluid ratios, etc. It can solve the problems of pH value fluctuation, large pH value fluctuation, and difficult control, etc., and reduce labor strength, prolonging operating life, and avoiding the effect of large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

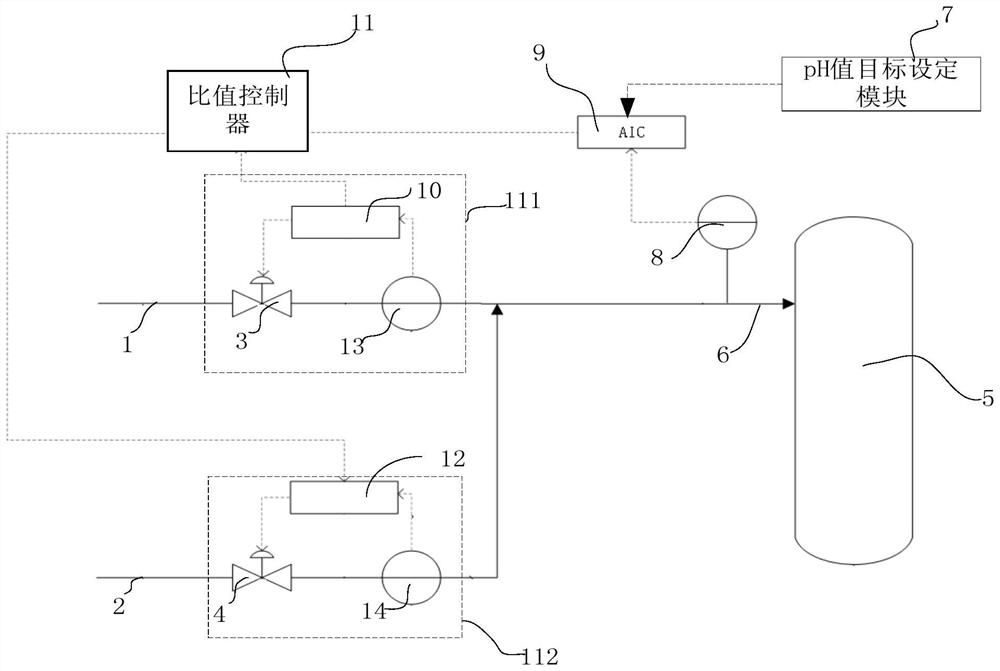

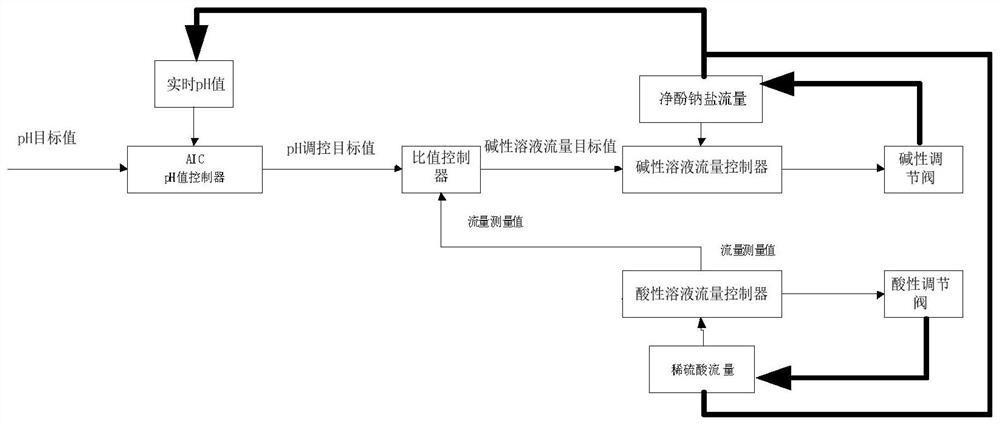

[0044] A pH online measuring meter is installed in the feed inlet pipeline of the separation tower of the dephenolization device. According to the real-time pH measurement value of the feed in the pipeline measured by the pH online measuring meter, the staff manually increases or decreases the net phenolic sodium salt flow rate. Adjust the pH value of the feed in the pipeline so that the pH of the feed liquid entering the separation tower meets the requirements, but the way of adjusting the pH value by repeatedly manually adjusting the addition and subtraction of the feed liquid is difficult to control and easily causes large fluctuations in the pH value , and will increase the labor intensity of the staff. In order to solve the above problems, a system for regulating the pH value of the dephenolization device is proposed in this embodiment, see figure 1 , before the feed liquid enters the separation tower of the dephenolization device, the pH value of the feed liquid is regul...

Embodiment 2

[0055] In this embodiment, the acid pipeline 1 is also provided with an acid solution flow meter 13, the acid solution flow meter 13 is used to measure the flow of the acid solution in the acid pipeline 1, and the flow measurement value is transmitted to the acid solution flow controller 10, see figure 1 , acid solution flow, 13, acid solution flow controller 12 and acid regulating valve 3 form an acid flow PID control loop 111, in order to achieve real-time feedback, the purpose of stable pH control.

[0056] Preferably, the alkaline pipeline 2 is also provided with an alkaline solution flowmeter 14, which is used to measure the flow of the alkaline solution in the alkaline pipeline 2, and transmits the flow measurement value to the alkaline solution flow controller, and the alkaline solution flowmeter 14. The alkaline solution flow controller 12 and the alkaline regulating valve 4 form an alkaline flow PID control loop 112 to achieve real-time feedback and stable pH control. ...

Embodiment 3

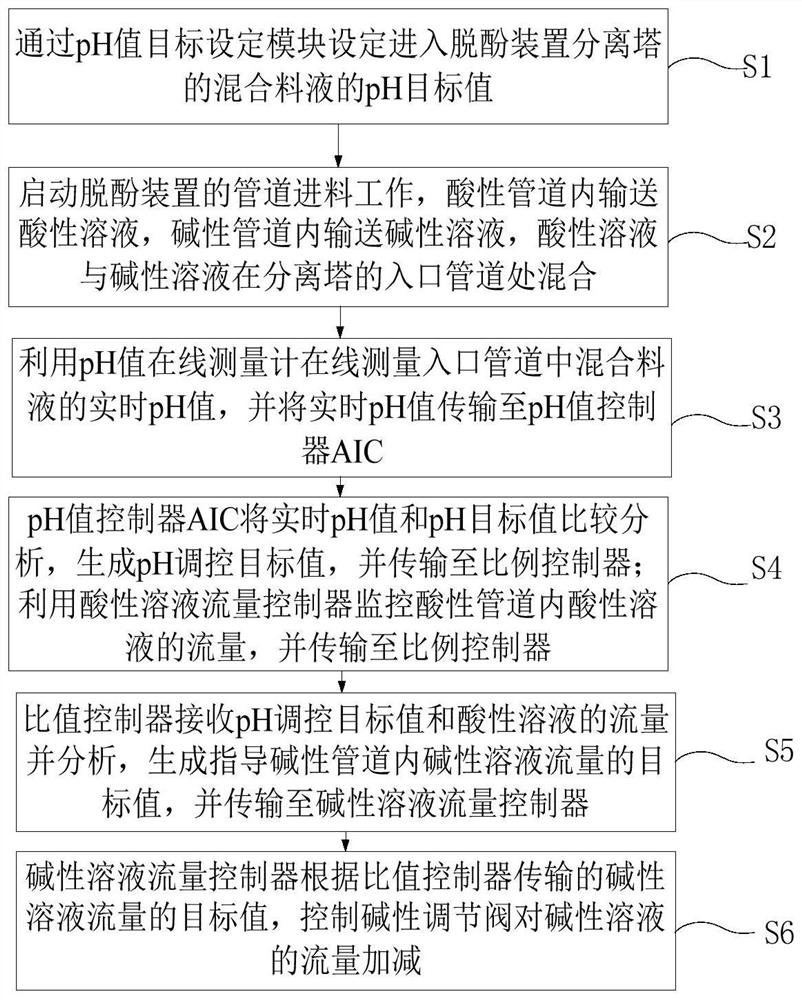

[0058] see image 3 , based on the system of embodiment 1 and embodiment 2, a method for regulating the pH value of the dephenolization device is proposed in the present embodiment, and the method includes the following steps:

[0059] S1. Set the pH target value of the mixed material liquid entering the separation tower of the dephenolization device through the pH value target setting module;

[0060] S2. Start the pipeline feeding work of the dephenolization device, transport the acidic solution in the acidic pipeline, transport the alkaline solution in the alkaline pipeline, and mix the acidic solution and the alkaline solution at the inlet pipeline of the separation tower;

[0061] S3. Use the online pH meter to measure the real-time pH value of the mixed material liquid in the inlet pipeline online, and transmit the real-time pH value to the pH controller AIC;

[0062] S4. The pH value controller AIC compares and analyzes the real-time pH value and the pH target value, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com