Hollow planetary reducer

A planetary reducer, hollow technology, applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of inability to meet the requirements of precision machinery, increase the overall volume of the reducer, occupy space, etc., to achieve internal space configuration optimization, The effect of reducing the occupied volume and reducing the rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

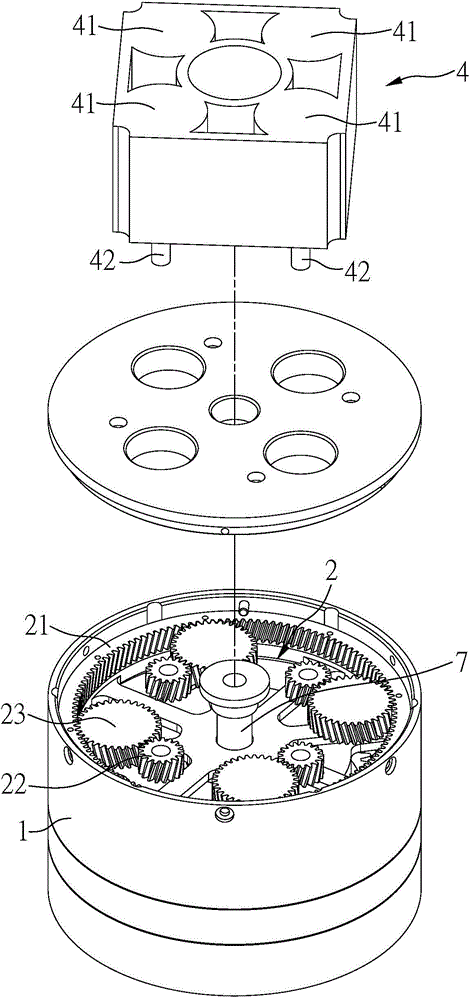

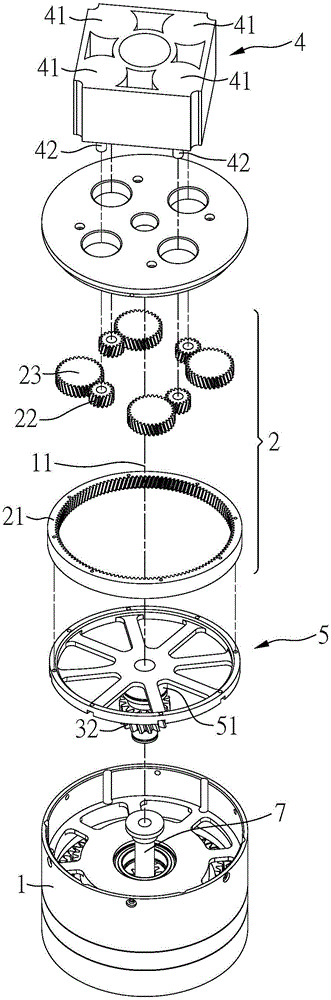

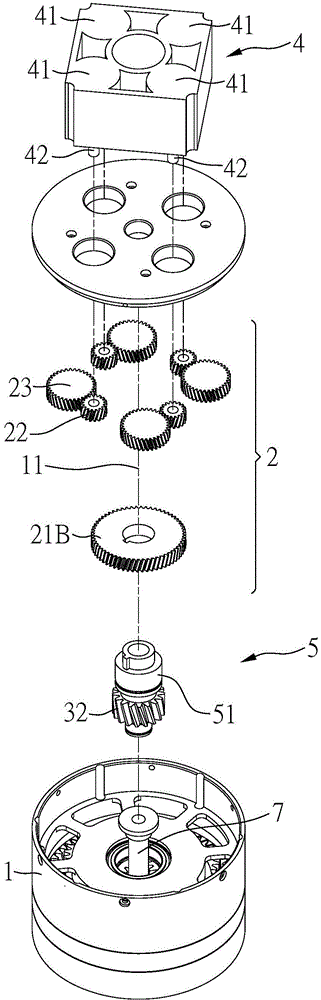

[0019] see Figure 1 to Figure 6 , the one shown is the hollow planetary reducer provided by the present invention, which has a body 1, and the body 1 is provided with a first gear 21, a second gear 31 and a sun gear 32 arranged along the same axis 11 , wherein the first gear 21 and the second gear 31 are located on both sides of the main body 1 respectively, and define a primary reduction mechanism 2 and a secondary reduction mechanism 3 .

[0020] The above-mentioned second gear 31 is an internal gear. In detail, the second gear 31 is an annular structure with teeth on its inner surface. Accordingly, the inner side of the second gear 31 accepts meshing connection with other gears.

[0021] Such as figure 1 , figure 2 match Image 6 As shown, in this embodiment, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap