3D model lifting cylinder for 3D printer

A technology of 3D printers and lifting cylinders, which is applied to the sealing of engines, electromechanical devices, mechanical equipment, etc., can solve problems that affect printing quality, sealing performance cannot meet the requirements, gas waste, etc., and achieve the requirements of sealing and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the drawings and embodiments.

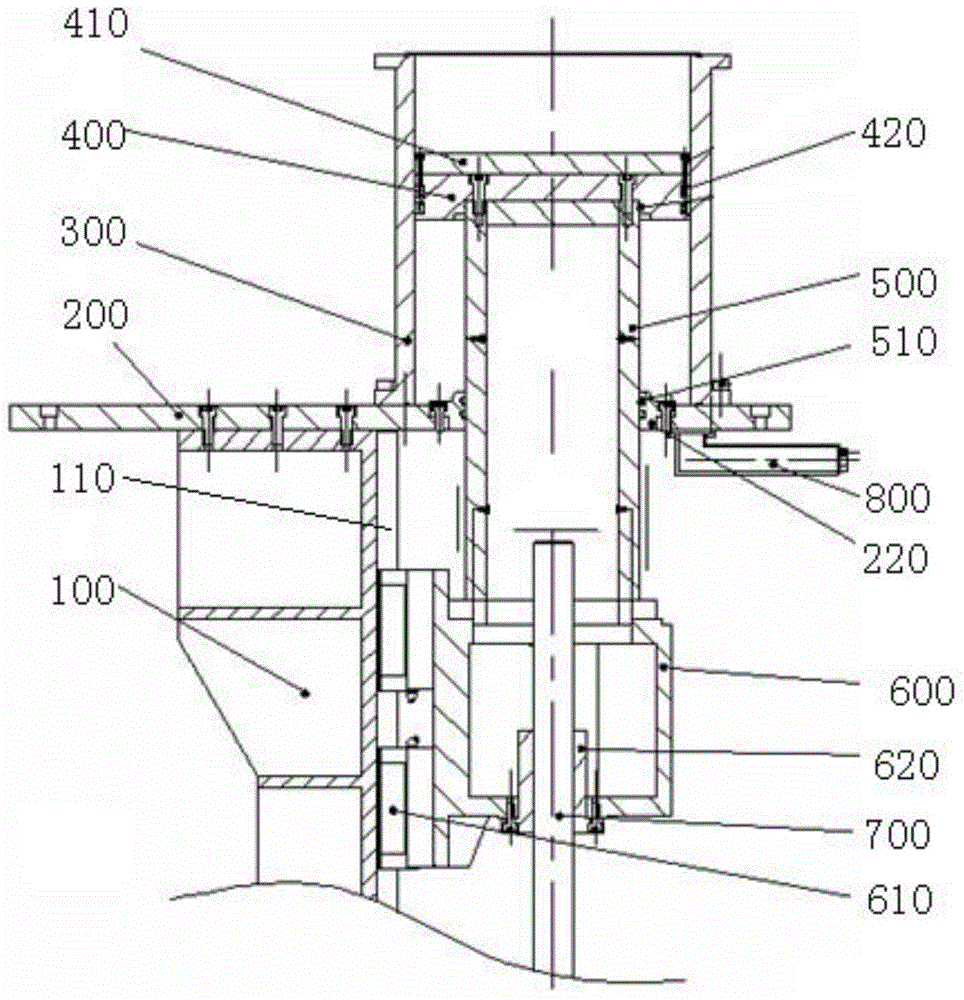

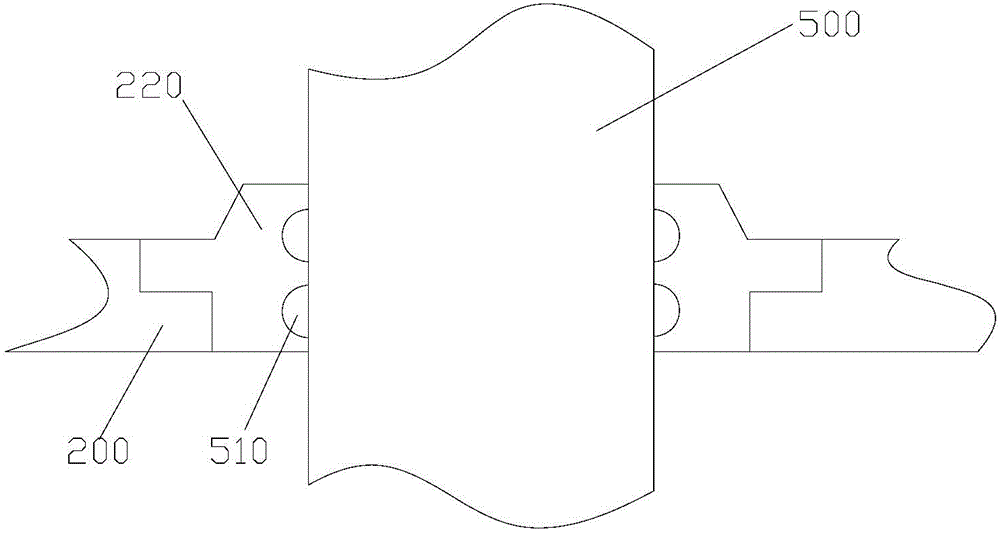

[0013] Such as figure 1 with figure 2 As shown, the 3D model lifting cylinder of the 3D printer includes a bracket 100, a bottom plate 200, a cylinder block 300, a piston 400, a guide rod 500, a nut seat 600, and a screw rod 700. The bottom plate 200 is fixed on the bracket 100 and the cylinder block 300 Fixed on the bottom plate 200, the bottom plate 200 is provided with a guide rod through hole; the bracket 100 is provided with a slide rail 110, and the nut seat 600 is provided with a sliding block 610. The sliding block 610 is clamped to slide on the slide rail 110, so The screw rod 700 is connected to the nut seat 600 through the screw nut 620, and the screw rod 700 is externally connected to the servo motor; the upper end of the guide rod 500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com