Outdoor unit of variable refrigerant flow air-conditioning system and variable refrigerant flow air-conditioning system

A multi-connection system, outdoor unit technology, applied in compressors, refrigerators, mechanical equipment, etc., can solve the problems of compressor wear and oil return bias, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

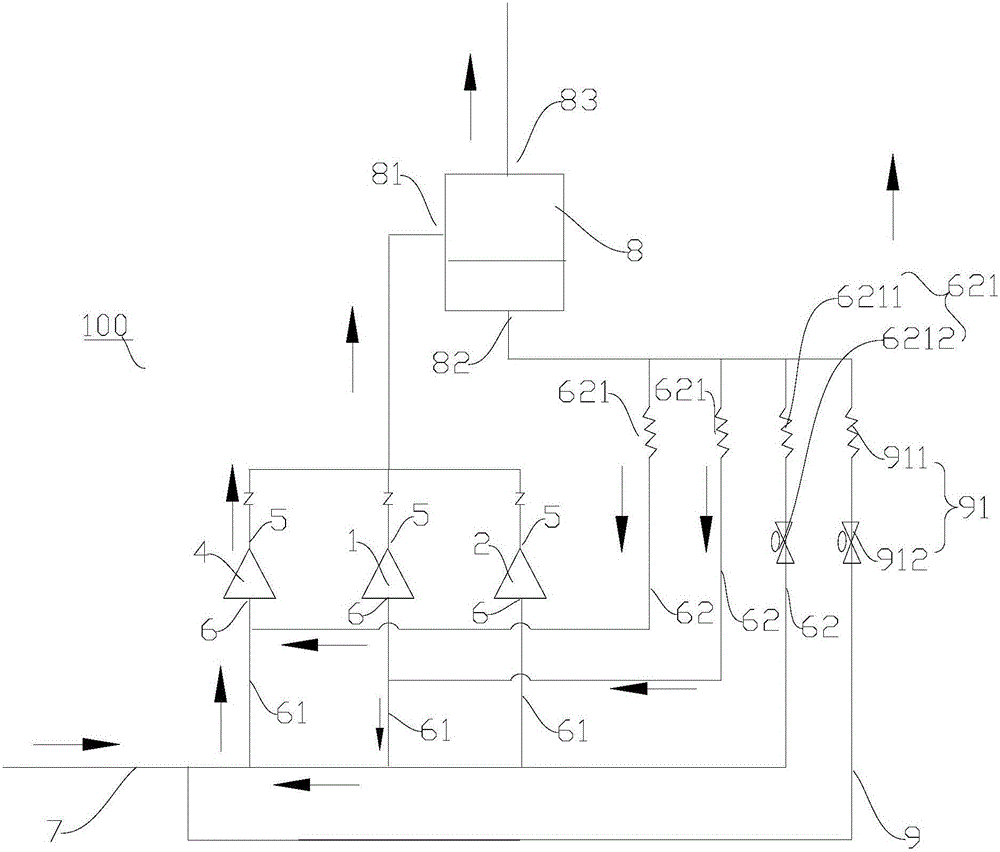

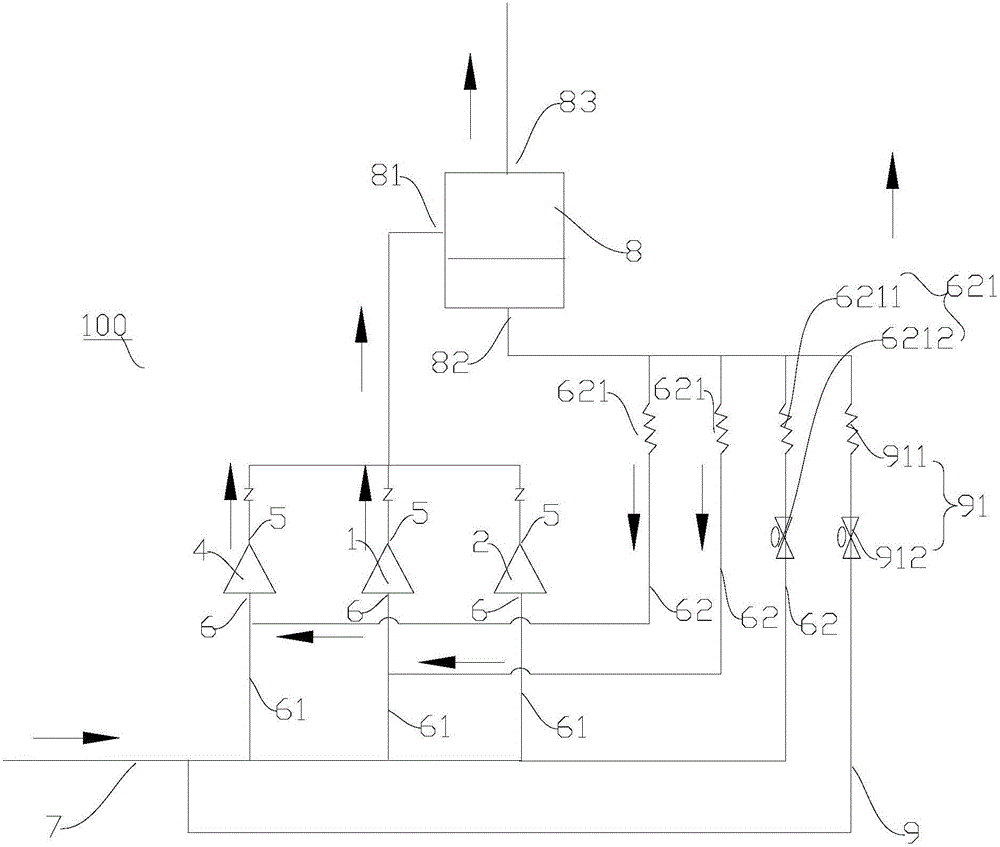

[0055] Such as Figure 1-Figure 3 As shown, the outdoor unit 100 of the multi-connected system in this embodiment includes a main air return pipe 7, a main compressor 4, a supplementary oil return pipeline 9 and two auxiliary compressors (namely the first auxiliary compressor 1 and the second auxiliary compressor 1). Auxiliary compressor 2) and an oil separator 8.

[0056] Each compressor has an air return port 6 and an exhaust port 5 , and the air return port 6 of each compressor is connected to the main air return pipe 7 through a corresponding sub-air return pipe 61 .

[0057] The oil separator 8 includes an inlet 81 , an oil outlet 82 and a discharge port 83 , the inlet 81 is connected to the exhaust port 5 of each compressor, and a sub-oil return pipeline 62 is connected between each sub-return pipe 61 and the oil outlet 82 . Each sub-oil return pipeline 62 is connected in series with a first throttling device 621 having throttling and pressure-reducing functions to redu...

Embodiment 2

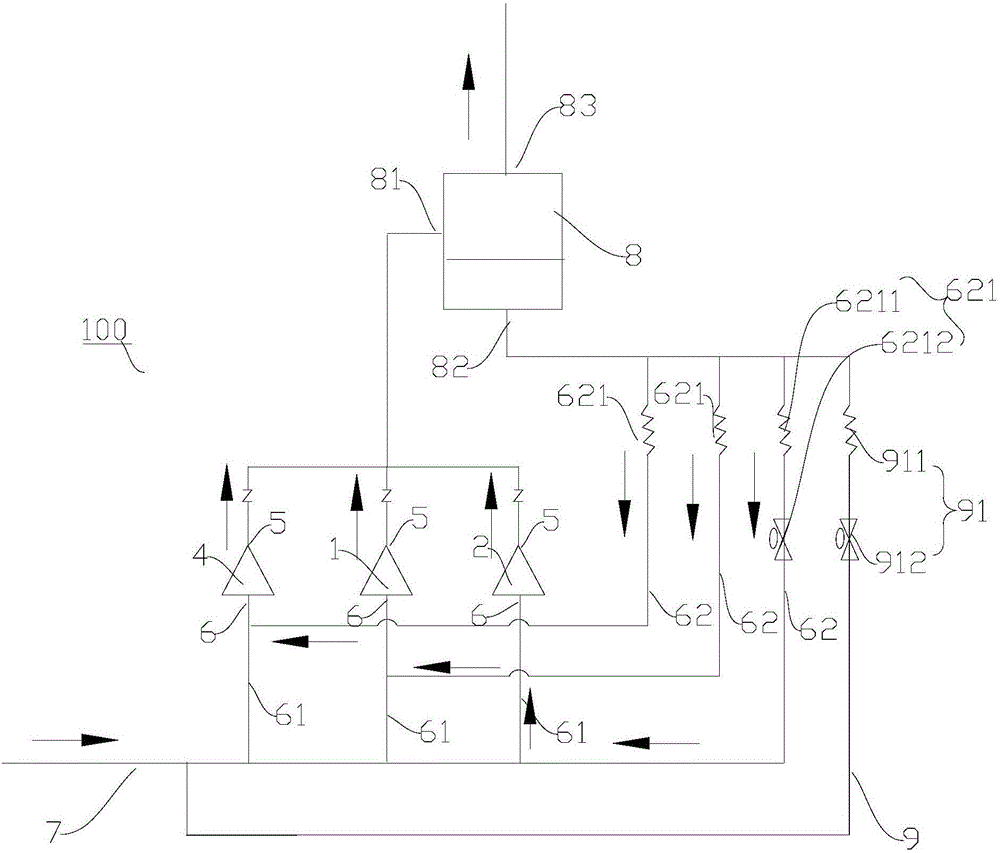

[0066] Such as Figure 4 As shown, the outdoor unit 100 of the multi-connected system in this embodiment includes a main air return pipe 7, a main compressor 4, a supplementary oil return pipeline 9 and three auxiliary compressors (namely the first auxiliary compressor 1, the second Auxiliary compressor 2 and a third auxiliary compressor 3) and an oil separator 8.

[0067] Each compressor has an air return port 6 and an exhaust port 5 , and the air return port 6 of each compressor is connected to the main air return pipe 7 through a corresponding sub-air return pipe 61 .

[0068] The oil separator 8 includes an inlet 81 , an oil outlet 82 and a discharge port 83 , the inlet 81 is connected to the exhaust port 5 of each compressor, and a sub-oil return pipeline 62 is connected between each sub-return pipe 61 and the oil outlet 82 . Each sub-oil return pipeline 62 is connected in series with a first throttling device 621 having throttling and pressure-reducing functions to redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com