Fully automatic pin pressing and testing all-in-one machine

A fully automatic, all-in-one machine technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high labor intensity, high production cost, and unguaranteed product quality, and achieve high automation, compact structure, working procedures and detection Results Precise and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

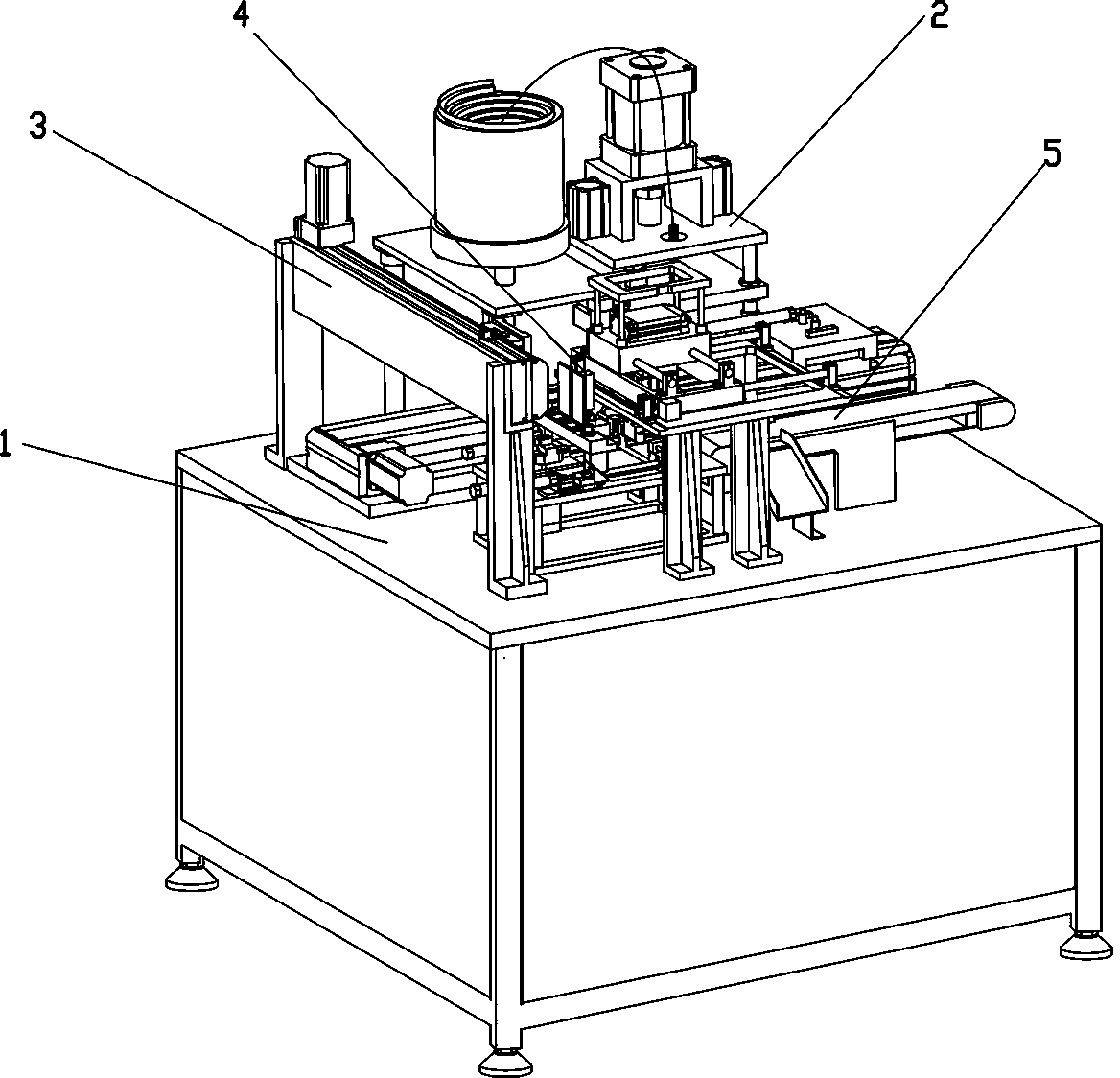

[0032] attached figure 1 Middle machine base 1, pressing pin mechanism 2, clamping mechanism 3, detection mechanism 4, conveying mechanism 5.

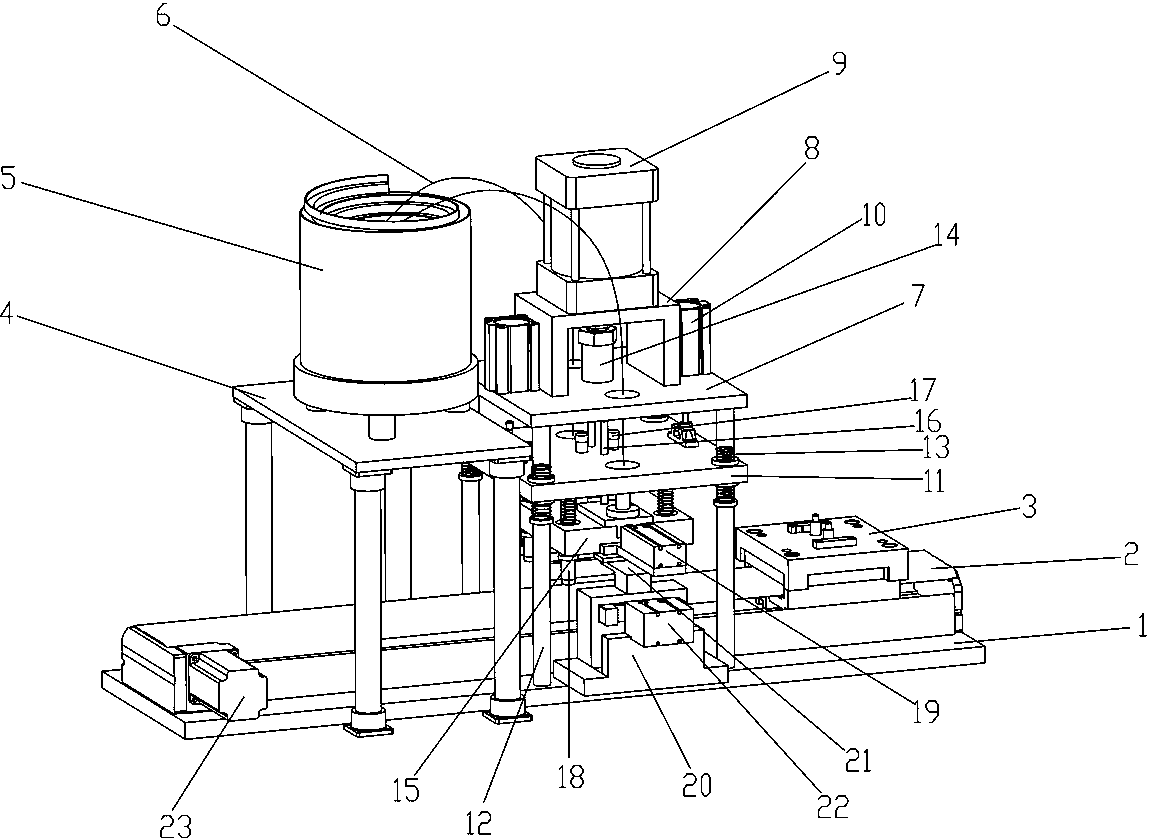

[0033] attached figure 2 Middle fixed plate 1, wire module 2, workpiece transfer jig 3, moving cylinder 23, support frame 4, feeding mechanism 5, pin feed pipe 6, pressing pin assembly, positioning device, wire module 2 is laid horizontally On the fixed plate 1, the workpiece transfer fixture 3 is set on the track above the line module 2, and can move along the track as required; the moving cylinder 23 is installed at the end of the line module 2; the feeding mechanism 5 is set on the fixed part of the support frame 4 On the plane of the plate 1, one end of the pin feeding pipe 6 is connected to the pin feeding mechanism 5, and the other end is connected to the pin pressing assembly; Mechanism, the depressing cylinder group is supported and connected by the guide post 12 and located on the upper part of the depressing plate 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com