Simple cable fixing rack

A fixing frame and cable technology, applied in the direction of electrical components, etc., can solve the problems of increased cost, easy corrosion of angle iron brackets, and many processes, and achieve the effects of prolonging service life, stable welding method, and flexible and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

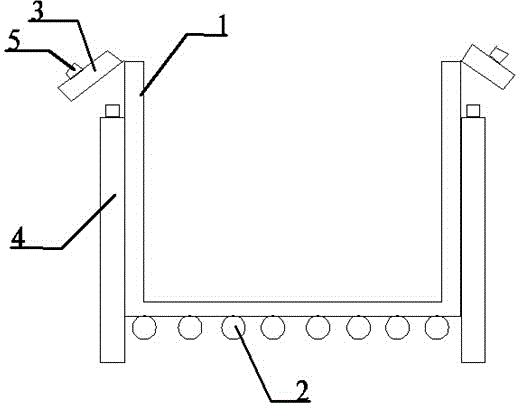

[0019] A simple cable fixing frame is composed of transverse ribs 1 and longitudinal ribs 2, the cross section of the fixing frame is a U-shaped groove structure, and the longitudinal ribs 2 are fixedly arranged on the outside of the transverse ribs 1.

Embodiment 2

[0021] Example 2 as figure 1 As shown, it is improved on the basis of Example 1. Its transverse reinforcement 1 and longitudinal reinforcement 2 are metal pipes, the horizontal reinforcement 1 is a U-shaped structure, and the longitudinal reinforcement 2 is a linear structure. The horizontal reinforcement 1 and the longitudinal reinforcement 2 are fixed by welding. . Compared with the existing fixing frame, the material cost is reduced, the degree of combination is more perfect, and the grid structure makes the installation easier, and it is easier and faster to overhaul the line.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1, and a movable cable splint 3 is respectively arranged on both sides of its transverse rib 1 . There will be shaking when the cable is connected out. Once the cable shakes, it will wear the edge of the cable fixing frame, causing the cable to be worn out and scrapped. The movable cable splint can reach the splint. wear and tear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com