Cable fireproof device and using method thereof

A fire prevention device and cable technology, which is applied in the direction of measuring devices, electrical components, fire rescue, etc., can solve the problems of single fire extinguishing effect and limited fire extinguishing effect, and achieve the effect of sealing and easy plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

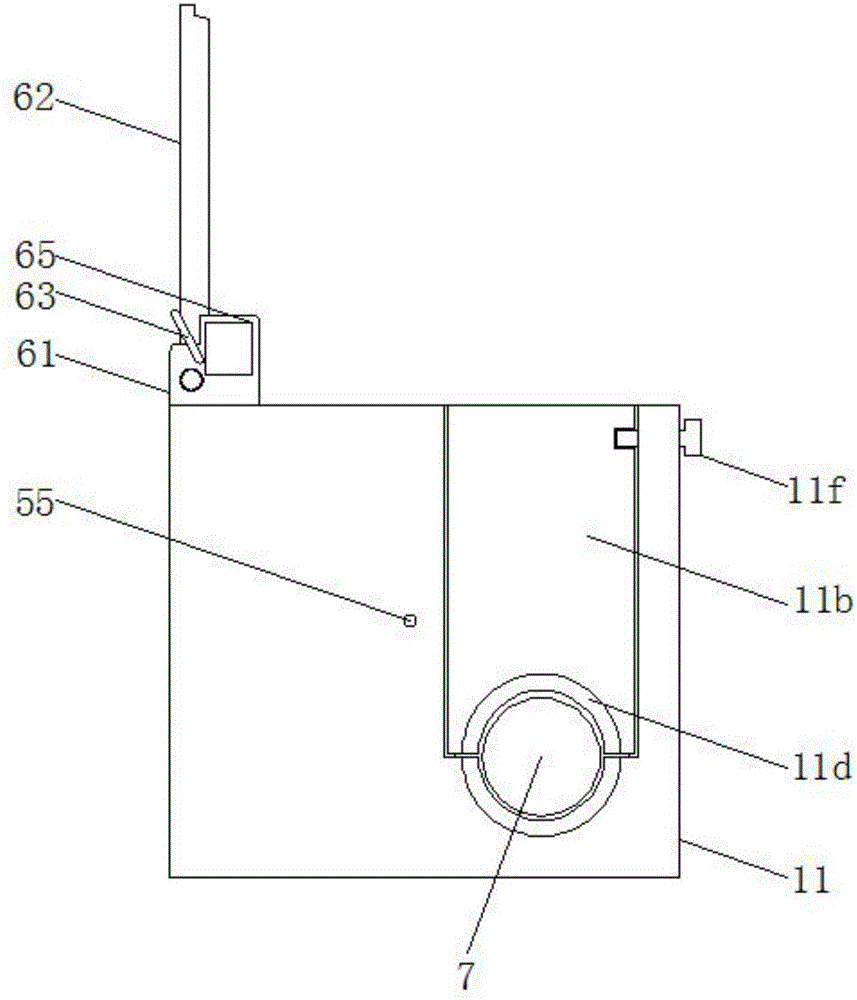

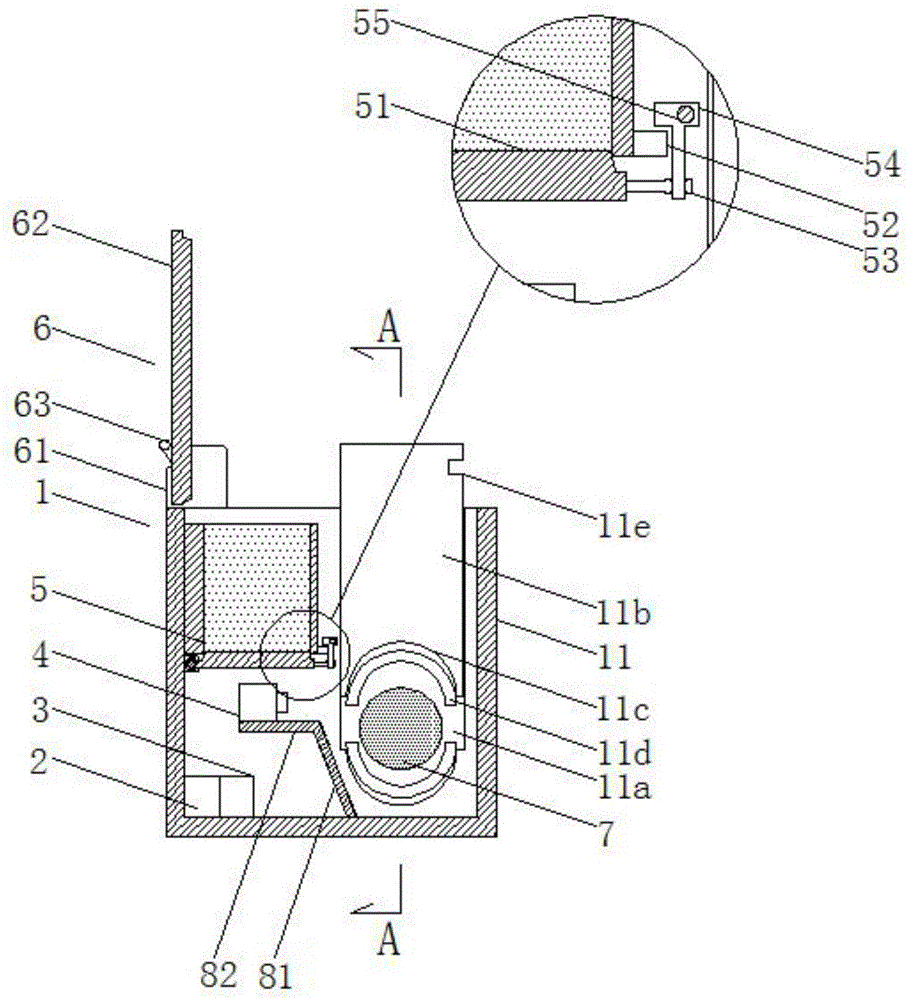

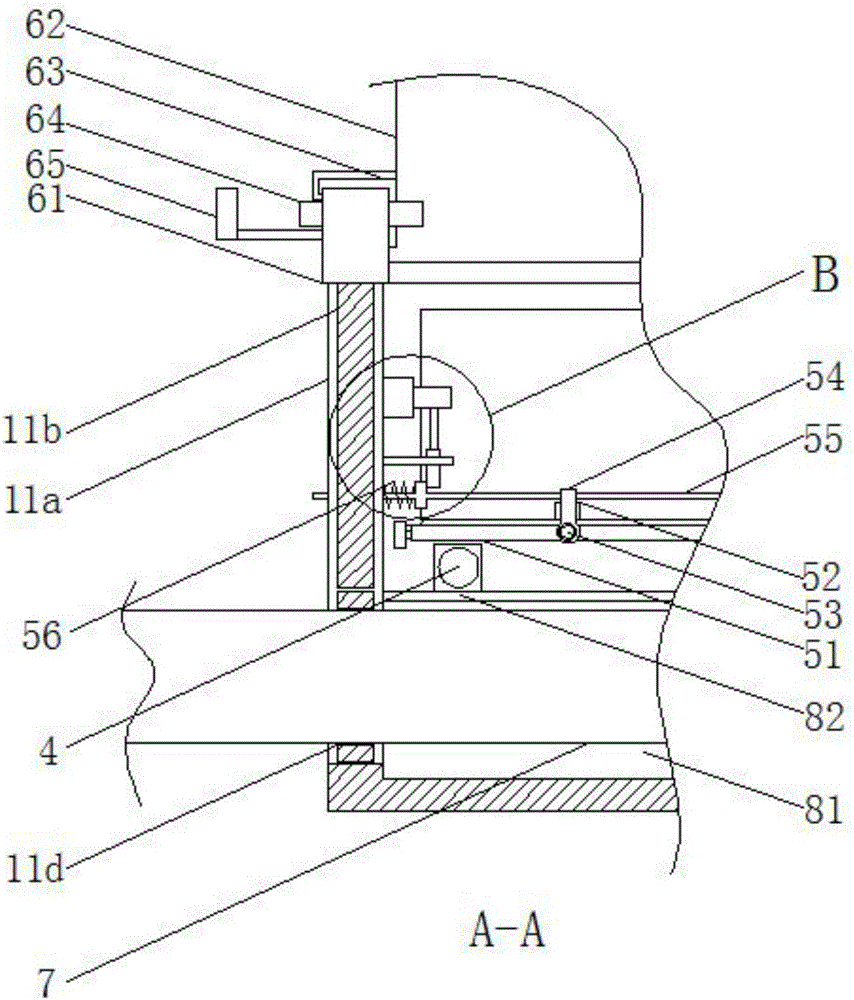

[0040] A cable fire protection device, characterized in that: it includes a horizontally arranged pipe 11 for covering cables;

[0041] The pipe 11 is a hollow pipe with an open upper end, a pair of side walls corresponding to the length direction of the pipe 11 are provided with a downwardly disposed rectangular slot 11a, and a rectangular insert 11b is inserted in the rectangular slot 11a. The lower horizontal sides of the rectangular board 11b and the rectangular slot 11a are symmetrically provided with a semicircular groove 11c for clamping the cable 7;

[0042] A temperature sensor 2 is provided behind the lower bottom of the pipeline 11, and the temperature sensor 2 is electrically connected to a control device 3, and the control device 3 is also electrically connected to at least one automatic fire extinguisher 4, and the nozzle of the automatic fire e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com