Real-time monitoring device and method for cutting force signals in machining process

A processing process and real-time monitoring technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of time waste, not easy to carry, complicated connection, etc., and achieve simple and convenient use, strong versatility and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in combination with specific embodiments.

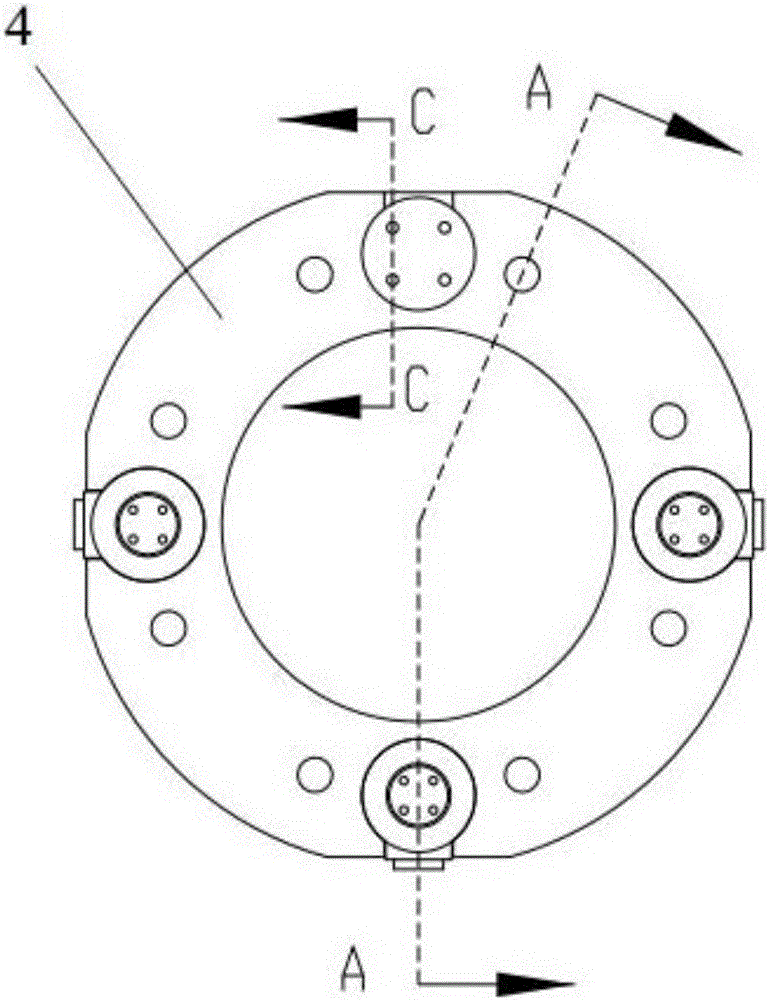

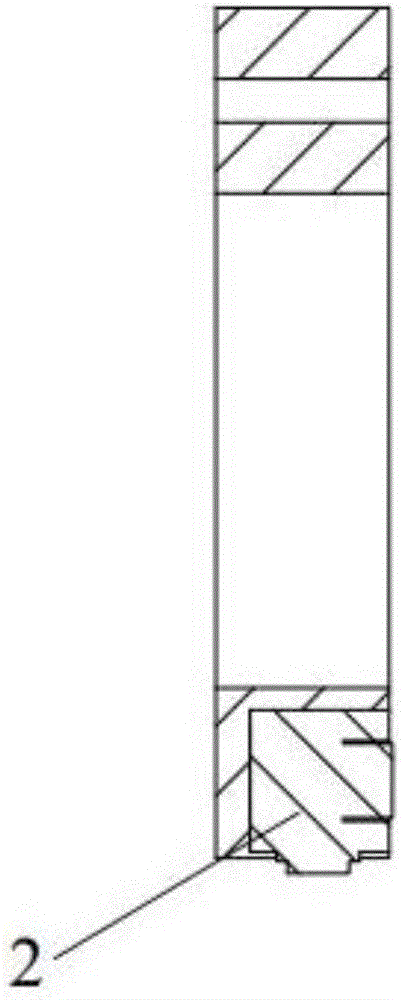

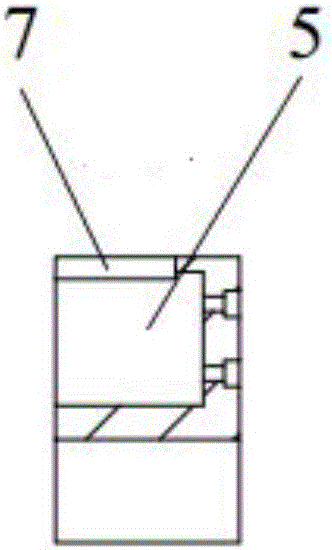

[0017] As shown in the drawings, the present invention is a real-time monitoring device for cutting force signals during machining, which includes an annular force-measuring device 4, and the annular force-measuring device 4 includes a body with a hole in the middle, and the The annular force measuring device 4 is set on the electric spindle body 1 through the middle opening and clamped and fixed between the electric spindle flange 6 and the fixed flange 3 of the equipment. The clamping and fixing can be done through the ring force measuring device 4, the electric The main shaft flange 6 and the fixed flange 3 of the equipment are fixed by bolts. On the body, there are four force sensor placement holes 5 at intervals of 90 degrees in the same circumferential direction, and a force sensor placement hole 5 is fixed in each force sensor placement hole 5. A three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com