Method for dressing polishing pads

A polishing pad and dresser technology, applied in the field of polishing pads, can solve the problems of unsatisfactory polishing pads and non-permanent polishing pad effects, and achieve the effects of increasing removal rate, improving plane parallelism, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

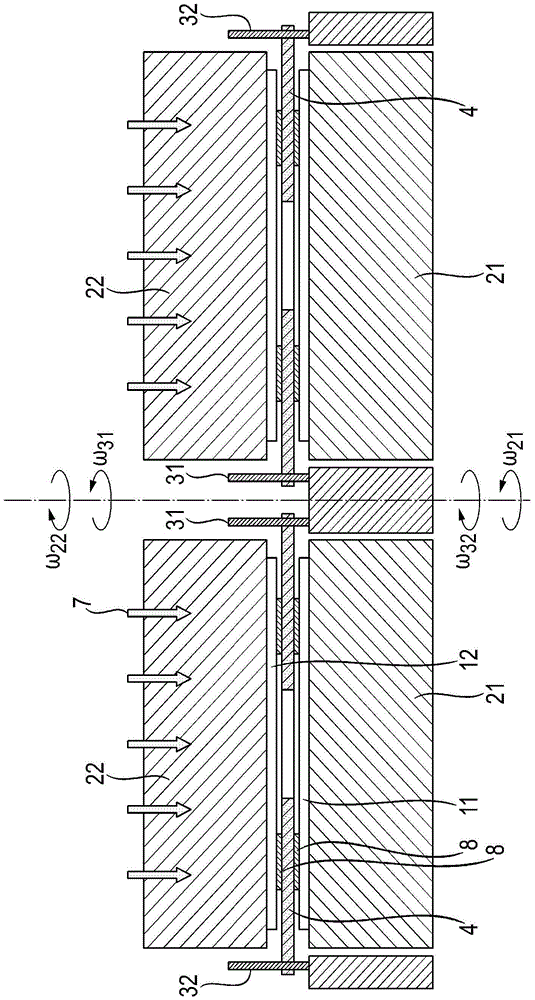

[0051] As already stated, the method according to the invention can be carried out both with a device for polishing a semiconductor wafer on one side and with a device for polishing a semiconductor wafer on both sides. If an apparatus for double-sided polishing of a semiconductor wafer is used, a dresser 4 can be used instead of the carrier plate used in the polishing process.

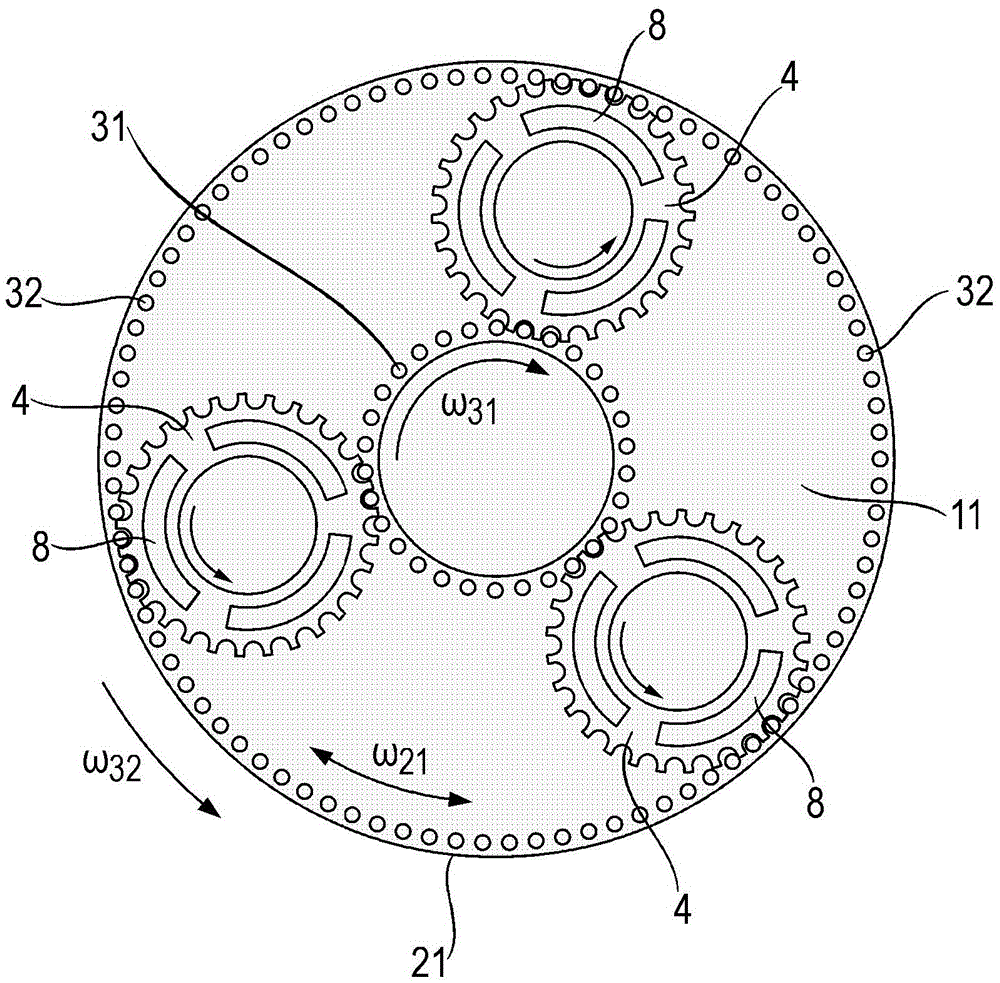

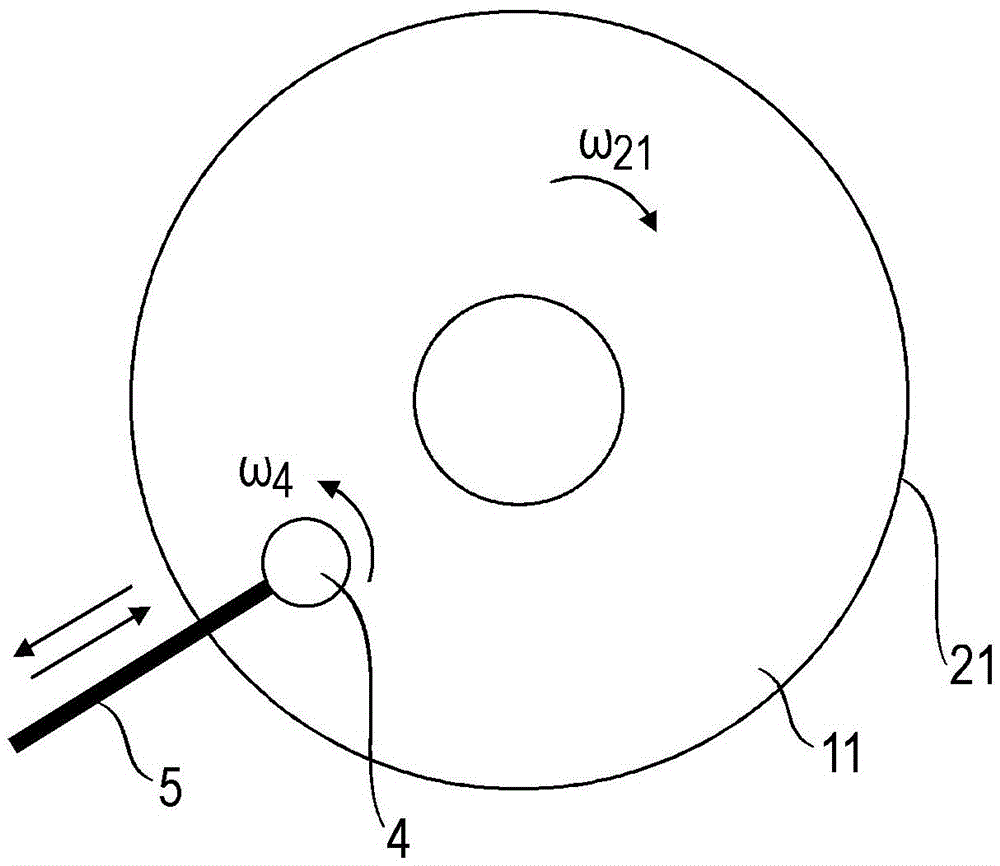

[0052] When using a device for double-sided polishing of semiconductor wafers, it is preferred to use an annular or disk-shaped dresser 4 with a peripheral gear ring in tooth mesh with an internal gear 31 and an external gear 32 . The rotational movement of the dresser 4 necessary for multidirectional dressing is ensured by the rotation of the two pinwheels. The side of the dresser 4 facing the upper polishing cloth 12 and the side of the dresser 4 facing the lower polishing cloth 11 are in each case preferably equipped with at least one dressing element 8 .

[0053] In a further embodiment of simult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com