U-shaped pin pull-out device

A kind of puller, U-shaped technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of easy injury, high labor intensity of operators, complicated pullout process, etc., to prevent bruises and improve the pullout effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

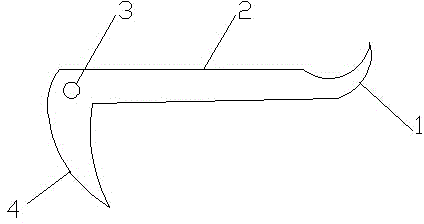

[0016] Embodiment one: if figure 1 As shown, a U-shaped pin puller includes a strip steel plate 2, and one end of the strip steel plate 2 is set as a small elbow 1 bent upward. The arcs on the left and right sides of the small elbow 1 intersect at the tip, which is conducive to the insertion of the present invention into the contact between the U-shaped pin and the fixture.

Embodiment 2

[0017] Embodiment two: if figure 1 As shown, on the basis of the first embodiment, the other end of the strip steel plate 2 is set as a large elbow 4 bent downward. The arcs on the left and right sides of the large elbow 4 intersect at the tip, which is conducive to the insertion of the present invention into the contact between the U-shaped pin and the fixture.

Embodiment 3

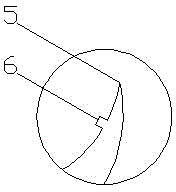

[0018] Embodiment three: as figure 2 As shown, on the basis of the first or second embodiment, a protrusion 5 is provided on the left side of the small elbow 1 near the tip 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com