Lifting platform utilizing high-strength round chain

A high-strength, circular chain technology, applied in the direction of lifting devices, lifting equipment braking devices, lifting frames, etc., can solve the problems of unstable lifting of heavy objects, unable to ensure uniform transmission of heavy objects, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

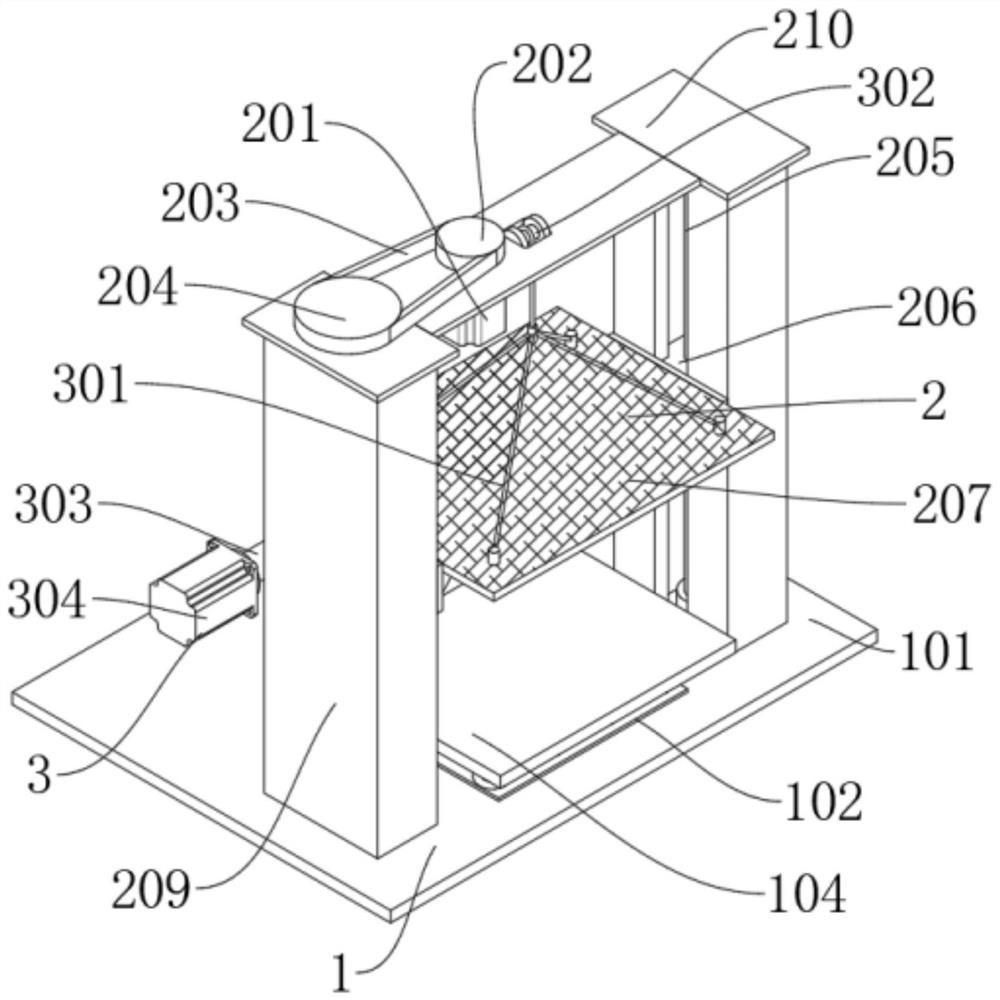

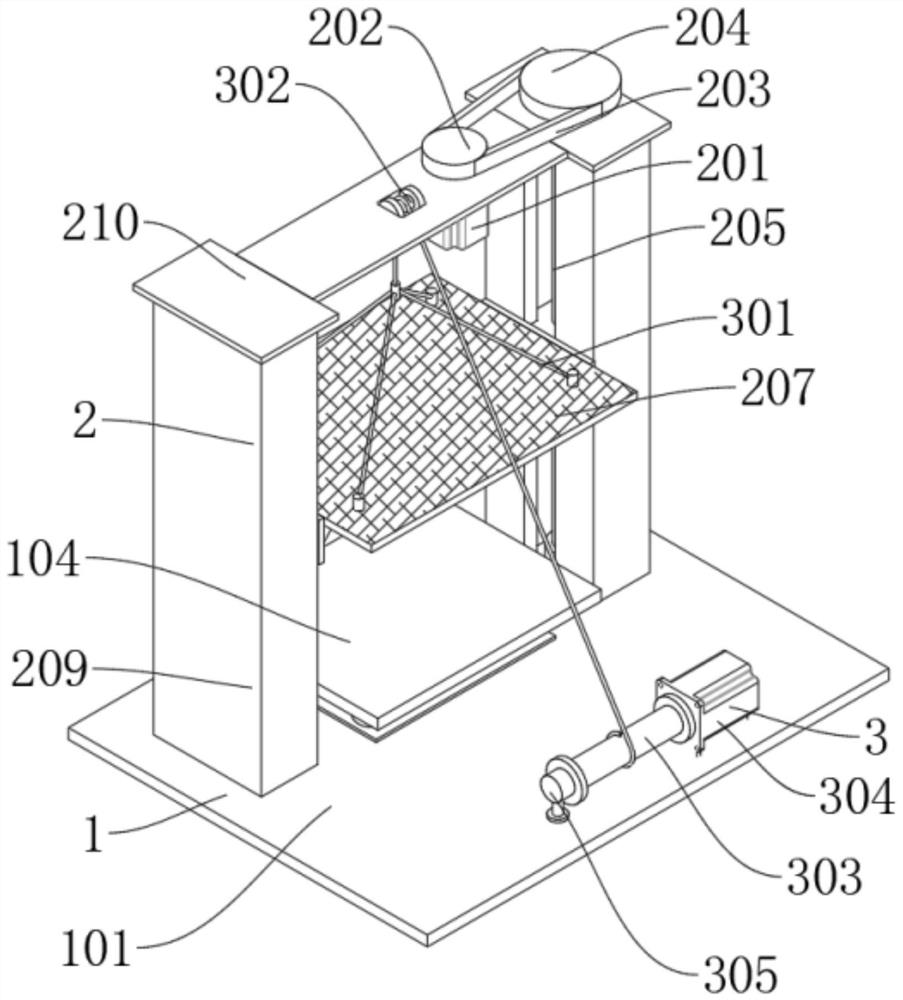

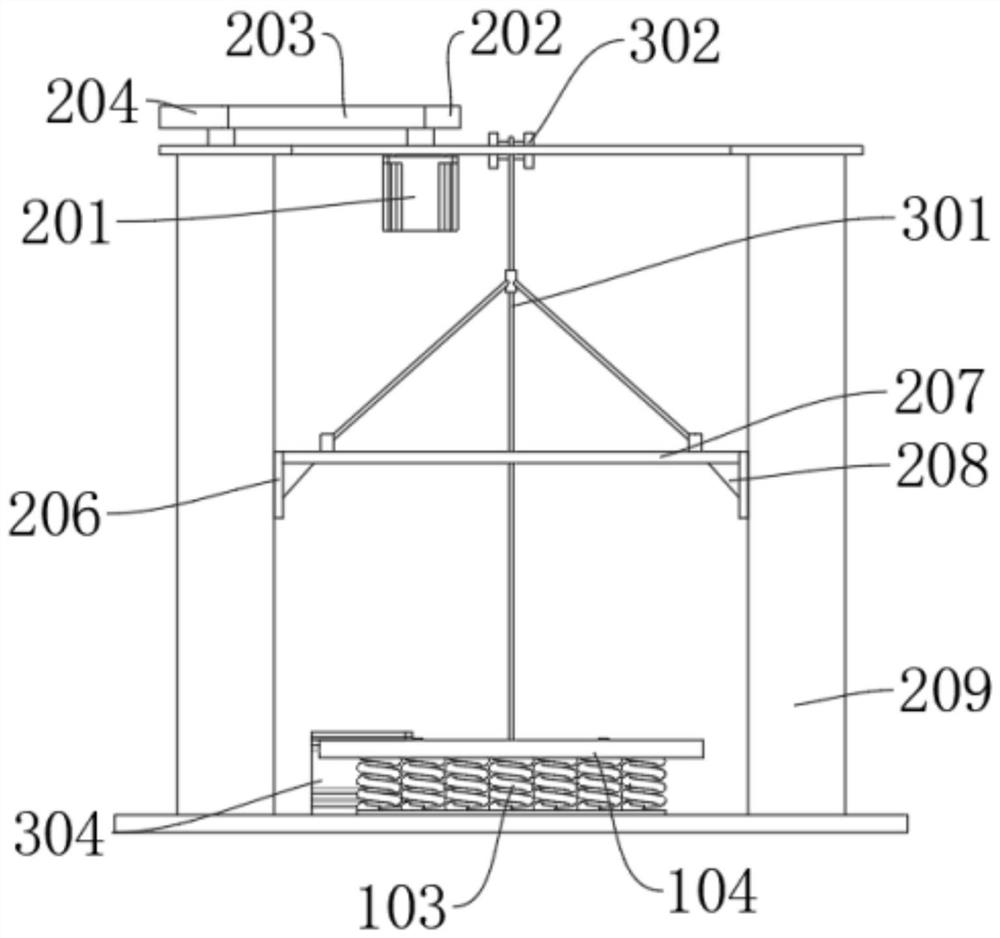

[0028] see Figure 1-Figure 4 , the present invention provides a lifting platform using a high-strength circular chain: it includes a slow pressure mechanism 1, and also includes a first lifting mechanism 3 that is convenient for the second lifting mechanism 2 to lift. The first lifting mechanism 3 includes a circular chain rope 301, The pulley 302, the rope roller 303, the second motor 304, the bracket 305, the round chain sling 301 is detachably connected to the upper part of the second lifting mechanism 2, the round chain sling 301 bypasses the pulley 302 and is wound on the rope roller 303, One side of the rope roller 303 is key-connected with a second motor 304, and the other side of the rope roller 303 is connected with a bracket 305 through a bearing.

[0029] On the basis of the above-mentioned embodiments: the slow pressure mechanism 1 includes a backing plate 101, a mounting plate 102, a slow pressure spring 103, and a contact pressure plate 104. A mounting plate 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com