a ribbon box

A technology for carbon ribbon cassettes and ribbons, applied in the directions of ink ribbon cassettes, printing, and inking devices, etc., can solve the problems that the coaxiality of the front and rear sections of the ribbon shaft cannot be guaranteed, whether it is in place or not, and the installation position is inaccurate. Improve accuracy and installation efficiency, convenient connection positioning, spring alignment and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

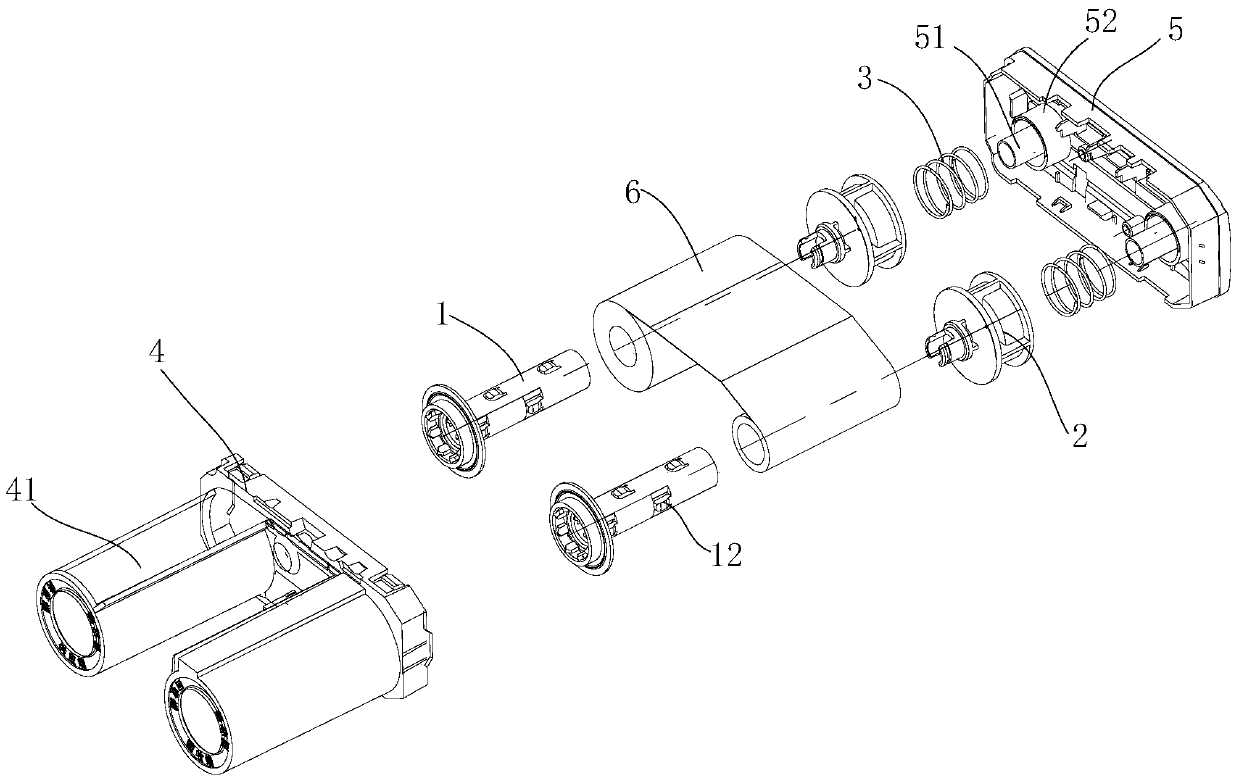

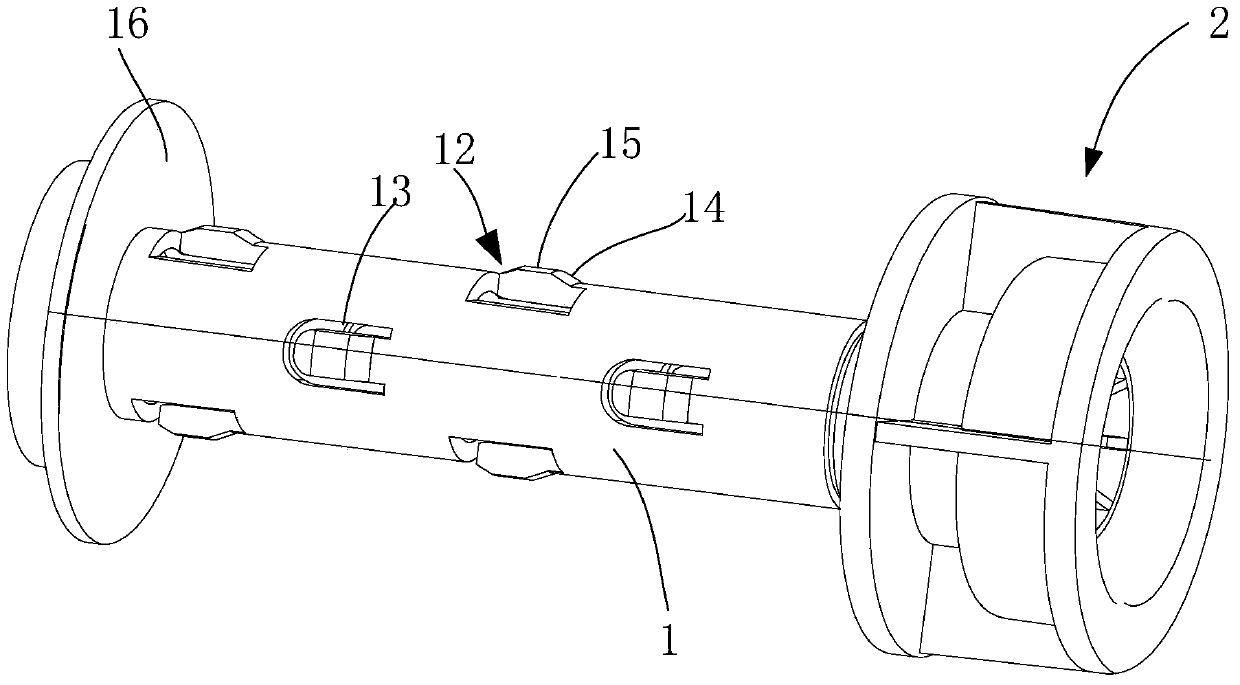

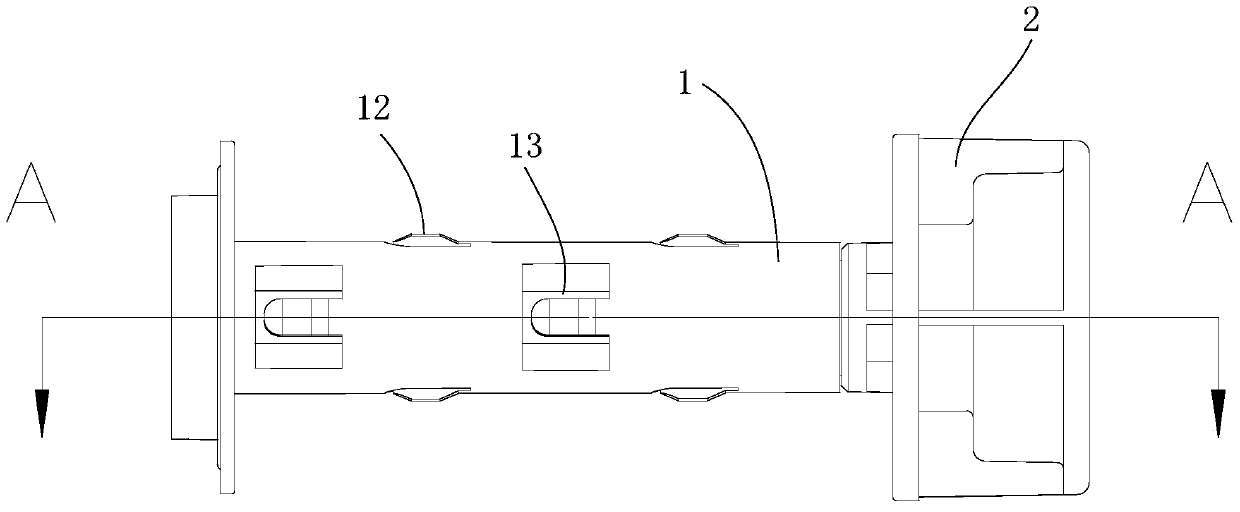

[0061] Such as Figure 1 to Figure 8 As shown, a carbon ribbon cassette includes an inner shell 4, an outer shell 5, and a ribbon shaft. The inner shell 4 and the outer shell 5 are connected by clamping. The ribbon shaft is installed in the inner shell 4. The rear end of the ribbon shaft is connected to the inner shell 4. Elastic elements 3 are arranged between the shells 5, and the carbon ribbon shaft includes a hollow support shaft 1 and a support member 2 for installing the carbon ribbon 6. The support member 2 and the rear end of the support shaft 1 are connected by a limiting structure, and the support shaft 1 The front end is the connection part that cooperates with the movement, and has flanges 16, meshing teeth 18, convex rings 17 for reducing friction, etc., and the limit structure can limit the relative movement between the support member 2 and the support shaft 1 in the axial or circumferential direction , realize the reliable connection of the support shaft 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com